The manufacturing industry is continuously evolving, driven by advancements in technology and the pursuit of increased efficiency.

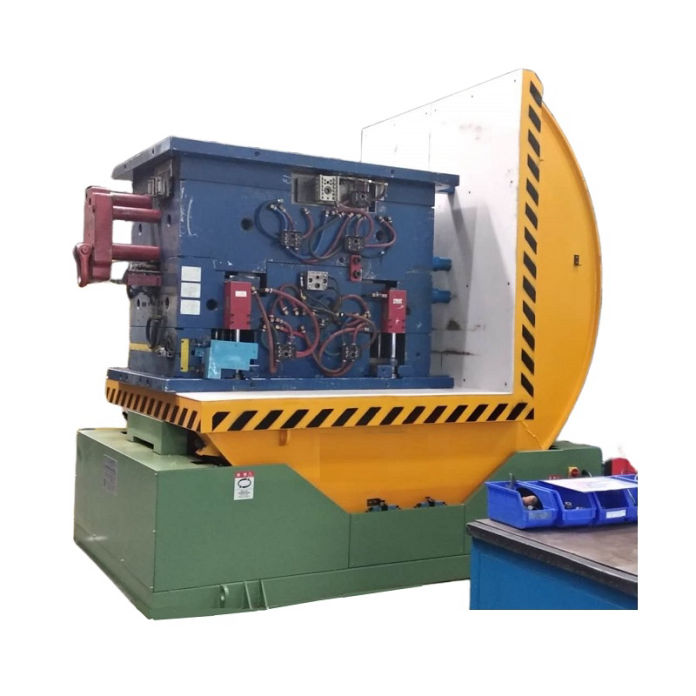

Mold upenders, also known as mold flippers or rotators, are at the forefront of this evolution, revolutionizing factory operations and paving the way for the future of manufacturing.

In this article, we will explore the transformative impact of FHOPE’s mold upenders and how they are leading the way towards a more streamlined and efficient manufacturing process.

Automation and Integration

Mold upenders are embracing automation and integration, which are essential components of the future of manufacturing. Such as Mold upender with roller conveyor can be seamlessly integrated into automated production lines, optimizing workflow and reducing the need for manual labor.

By incorporating mold upenders into a fully automated system, manufacturers can achieve higher levels of efficiency, precision, and productivity.

The ability to connect mold upenders with other manufacturing equipment through IoT (Internet of Things) technologies enables real-time data exchange and streamlined production management.

Smart Manufacturing and Data Analytics

Mold upenders are becoming smarter, thanks to the integration of data analytics and intelligent algorithms. This enables them to gather and analyze data from various sources, such as production rates, cycle times, and maintenance schedules.

By leveraging this data, manufacturers can gain valuable insights into their production processes, identify bottlenecks, and make data-driven decisions to optimize efficiency.

Predictive maintenance algorithms can also be implemented, allowing manufacturers to proactively schedule maintenance tasks and minimize unplanned downtime.

Enhanced Safety and Ergonomics

The future of manufacturing places a strong emphasis on worker safety and ergonomics, and mold upenders are leading the way in this regard.

These machines are equipped with advanced safety features, such as light fence, collision detection sensors, emergency stop buttons, and automated load balancing mechanisms.

By reducing the need for manual handling of heavy molds or dies, mold upenders minimize the risk of injuries and musculoskeletal disorders among workers.

This not only contributes to a safer working environment but also improves overall productivity by ensuring a healthy and motivated workforce.

Customization and Flexibility

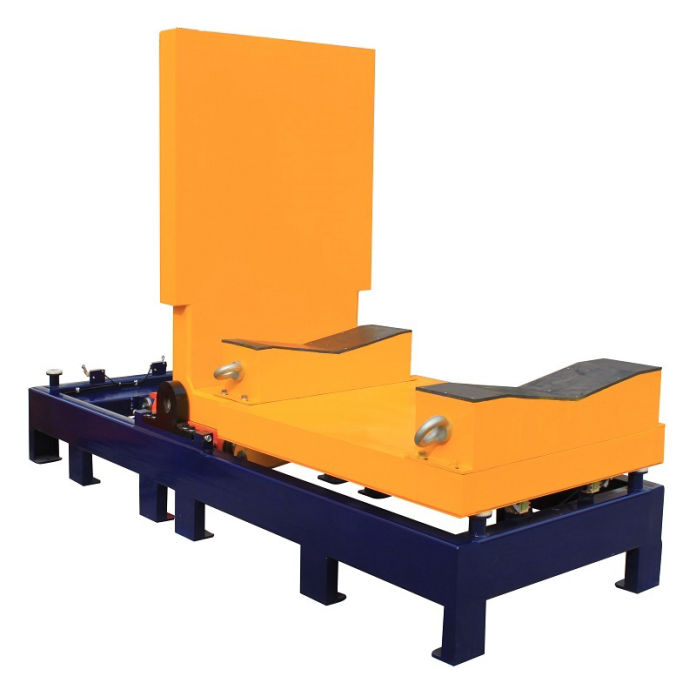

As customer demands become more diverse and personalized, mold upenders are evolving to offer greater customization and flexibility.

Manufacturers can now find mold upenders that can be easily adapted to handle molds or dies of various sizes, shapes, and configurations.

Adjustable rotation angles, programmable settings, and modular designs allow for quick and seamless customization to meet specific production requirements.

This flexibility enables manufacturers to efficiently produce a wide range of products while maintaining high-quality standards.

Sustainable Manufacturing

Sustainability is a key focus in the future of manufacturing, and FHOPE’s mold upenders contribute to this goal in several ways.

First, by optimizing production processes and reducing downtime, mold upenders help minimize energy consumption and waste.

Second, their automated features and precise positioning capabilities minimize material waste during mold changes.

Third, the integration of smart technologies and data analytics enables manufacturers to identify and implement energy-saving measures.

By incorporating mold upenders into their operations, manufacturers can make significant strides towards more sustainable and eco-friendly manufacturing practices.

Conclusion

The future of manufacturing is being reshaped by mold upenders, which are leading the way towards a more streamlined, efficient, and sustainable production process.

Through automation, integration, data analytics, and enhanced safety features, mold upenders are transforming factory operations. Their ability to adapt to customization needs and contribute to sustainable manufacturing practices makes them a vital asset for manufacturers across various industries.

As technology continues to advance, we can expect mold upenders to play an increasingly central role in shaping the future of manufacturing.