Introduction:

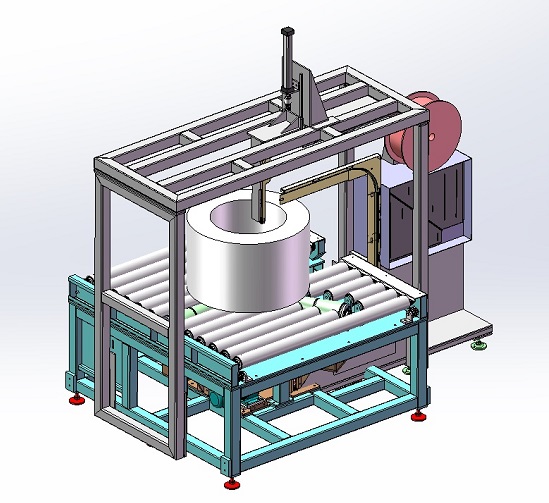

In metal smelting plants, the packaging process for steel coils is a critical stage that requires efficiency, accuracy, and safety. Automatic coil strapping machines play a significant role in optimizing this process.

These machines are designed to streamline the coil bundling process and offer numerous benefits, including increased productivity, improved worker safety, minimized product damage, and enhanced operational efficiency.

By considering key factors and leveraging the capabilities of these machines, metal smelting plants can optimize their packaging process.

Here are five ways steel coil strapping machines can help achieve that:

High-Temperature Adaptability:

Metal smelting plants often operate in high-temperature environments, especially during hot-rolled coil processing.

Automatic coil strapping machines must be equipped with high-temperature-resistant materials, cooling systems, and insulation measures.

This ensures the machines can function normally and withstand the heat.

By utilizing these features, plants can maintain consistent performance and prevent equipment failure in demanding conditions.

High-Speed Strapping Capability:

The production of steel coils involves rapid coil delivery, requiring the packaging machines to have high-speed strapping capabilities.

Automatic coil strapping machines should be designed to handle the fast-paced nature of the process.

With efficient and precise strapping, these machines reduce downtime and increase overall productivity.

They ensure coils are bundled promptly and securely, contributing to an optimized packaging process.

Handling of Heavy Coils:

Steel coils can be extremely heavy, often weighing tens of tons. Automatic coil strapping machines must have robust construction and advanced load-bearing mechanisms to handle these heavyweight coils safely and reliably.

The machines should be designed to support the weight, maintaining stability during the strapping process.

By ensuring proper load-bearing capacity, plants can optimize the packaging process and prevent accidents or damage caused by inadequate support.

Integration with the Packaging Process:

Seamless integration of automatic coil strapping machines with the overall packaging process is crucial for efficient material flow and synchronization with downstream operations.

These operations may include labeling, additional strapping, or wrapping.

By integrating the machines into the packaging line, plants can optimize productivity and minimize disruptions.

Smooth material flow and synchronized operations contribute to a streamlined and efficient packaging process.

Data Management:

Automatic coil strapping machines can incorporate data management systems to monitor and analyze operational parameters.

These systems can track production volumes, monitor machine performance, and generate reports for process optimization and quality control.

By leveraging data, manufacturers can identify bottlenecks, make informed decisions, and optimize the packaging process.

Analyzing operational parameters and performance metrics allows for continuous improvement and increased efficiency.

Conclusion:

Steel coil strapping machines play a crucial role in optimizing the packaging process in metal smelting plants.

By considering factors such as high-temperature adaptability, high-speed strapping capabilities, handling of heavy coils, integration with the packaging process, and data management, plants can enhance productivity, improve worker safety, minimize product damage, and achieve optimal efficiency.

Investing in robust and well-designed automatic coil strapping machines can significantly contribute to an optimized packaging process and overall operational success in metal smelting plants.