Coil Packing Solutions

Automatic Coil Packing Solution

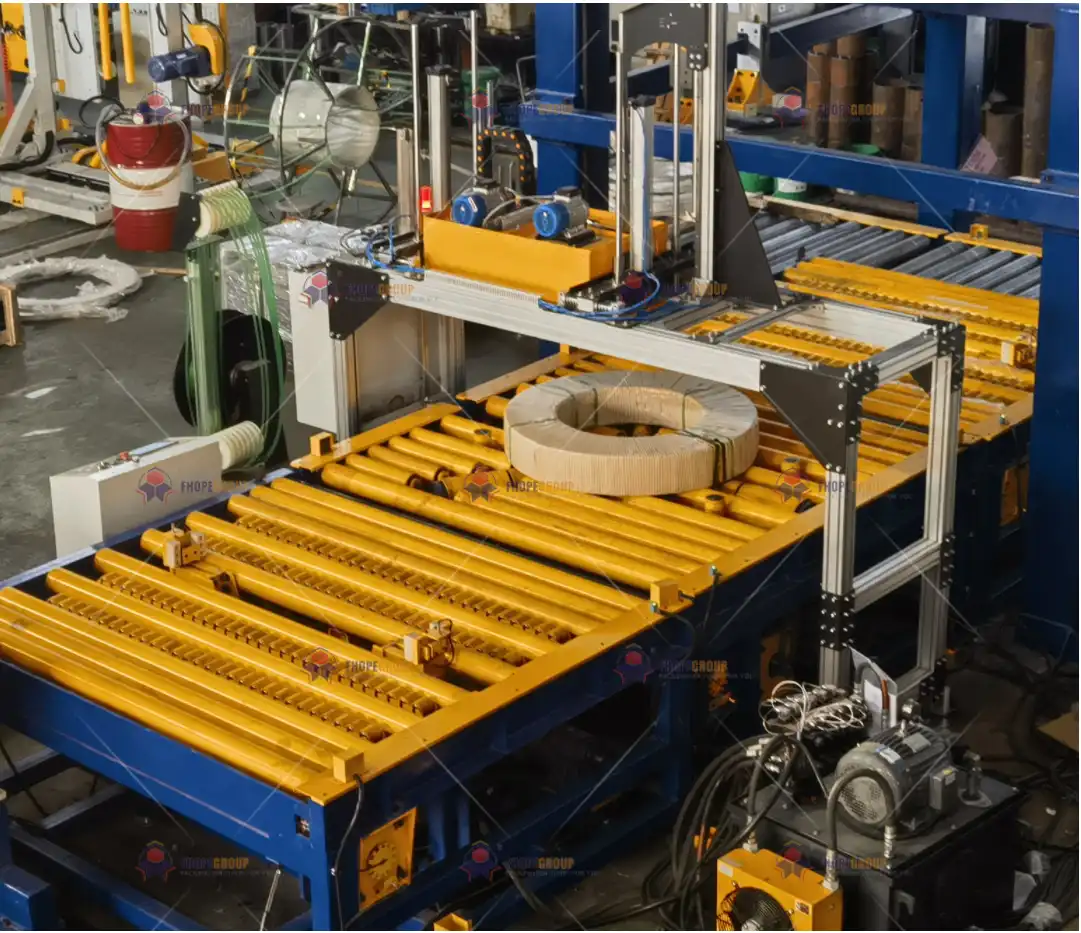

The coil packing line is a comprehensive system that combines the coil handling machine, coil packing machine, and strapping machine to automate the process from the production line to the warehouse with PLC program systme and ERP data system.

Handling steel coils manually is challenging due to their heavy weight. To ensure safety and improve efficiency in coil packing, many factories are in search of solutions to address the issues associated with coil status.

Automatic Coil Packing Solutions

The way to improve your coil packing from manually to automatically

REASONS FOR COIL PACKING LINE

01. High Efficiency Coil Handling

Effective coil management, packaging, palletizing by one people only...suited for various steel coil specifications..

02. Automated Process with Data Integration

Monitor every step with data creation that's compatible with ERP, MES systems from packaging to storage.

03. Improving the Packaging

Improved packaging and safeguarding of coil surface, strapping, and palletizing to meet diverse packaging objectives

04. Safety operation

Keep employees distant from the heavy coil packaging procedure and establish a safe work environment.

FHOPE offers a coil packing system that is tailored to meet the specific packing requirements of users to improving the packaging procession and packaging management. Our system includes various types of packing lines that seamlessly integrate with the silting line, coil downender, crane, fork-man, and more. Moreover, we provide a specialized hot mill coil packing system that guarantees the highest level of efficiency. By connecting with ERP system Whether it's coil information scanning, strapping, or packing, our flexible system significantly reduces labor costs associated with handling and stacking. It benefits not only in packaging, but also in the products management.

A. SLIT COIL HANDLING AND STACKING LINE

Automatic Coil

Handling

Increasing the handling speed

This is the solution mainly form helping to easy handling the slitting coil with slitting line. It is for seperating the steel coil from turnstile one by one that replace the manually operation with more safety and efficiency.

Specifications

Turnstile

Holds slit coils on arms

The turnstile is for storage the slit coils and turning for coil unloading , which equipped with two or four arms, is used for storing coil straps transferred from the slitting line. The arm designed with channel for C-hook or down ender coil pick up

Down ender

Coil pick up one by one

This equipment is coil lifter and turner that lifts each slit coil from the turnstile and 90 degree turning to the conveyor wiht ID to sky.

Semiauto Strapping Station

Rotation for strapping

It is economic solution to strap the coil, Semi-automatic strapping solution: facilitated by a hand tool with a turntable or a semi-automatic strapping head. The turn table for coil 360 degree turning to do coil starpping per strapping number

Centering Station

Aligns the coil for stacking

This device, including a lifting roller and pusher, guides the coil to the center of the conveyor for proper positioning. IT is necessary procession for precised coil stacking.

Stacking Machine

Transfers coils to the pallet individually

The crucial component is the coil stacking machine, designed to pick up the coil from centering position and stacking each coil on the pallet. The main driving system is by hydraulic system. This method offers a safer and easier alternative to other handling methods.

The solution for making the coil handling and packing in a pipe line

Providing Customized Solution per different Loads

The handling solution primarily focuses on lifting the coil from the coil car and transferring it into the stacking machine, serving as an alternative to traditional cranes or fork lifters.

B. SLIT COIL WRAPPING AND STACKING LINE

The solution to help you have a fast return on investment.

FHOPEPACK

Steel Coil Wrapping

Stacking line

Specifications

Turnstile

Integrated with the slitting line

This marks the beginning of the coil packing line. The coil car moves the slit coil from the winding machine to the turnstile.

Down Ender

Performs a 90-degree down ending

This equipment lifts the bare coil from the turnstile and down ends it onto the conveyor one by one. It includes a hydraulic station, coil lifter, and conveyor.

Automatic Strapping Machine

Designed for coil binding

The Automatic Strapping Machine is engineered to carry out the ID strapping of the coil packages autonomously. Manual operations can also be performed using the control desk screen or the button panel on the machine.

Automatic Wrapping Machine

Uses Paper/knit belt+stretch film

This packaging approach reduces the amount of air in the package by using tight layers of packing material, which decreases the chance of moisture formation and consequently the risk of corrosion or water spots. This machine significantly reduces labor requirements in the coil packing procedure.

Automatic Centering Machine

Aligns the coil for stacking

Automatic Stacker

Employs a fork arm type lifter

Handling speed: Can handle a coil every 70-120 seconds.

Max. Coil Weight: 6T

Strapping: By PET/STEEL

Packing Material: As per requirement

Control Level: Level 1-3

IoT: Yes

Compatible with: MES, ERP

Space: According to factory layout

Control System

System Integration

FHOPE provides a tailored coil packing system designed for various packaging objectives and budget levels. The packing system requires only 1-2 people for all operation steps. Depending on the handling method, the packing line can be designed with coil car feeding, crane loading, or even forklift in&out.

Automatic slitting coils packing solution with prefect ROI

Offering Tailored Solutions for Various Loads

The idea behind the coil packing line is to integrate the coil strapping machine and packing machinery for enhanced automation. The machine applies compact layers of packing materials across all surfaces of the coil.

C. SLIT COIL PACKAGING

STRAPPING LINE

From Automated coil packaging lines, through coil wrapping machinery to relevant packaging materials, Fhope provides a diverse array of packaging equipment covering a wide spectrum for coil objects.

Explore our comprehensive range of solutions by choosing the areas that best suit your needs.

Leading manufacturer

Coil Packing System

Specifications

Control System

Connection to MES System

The system integrates relevant management experiences, industrial practices, and information technology. It is designed to process and store production performance, quality, and material-tracking data promptly. This promotes communication across all departments and roles within the steel slitting plant, enhancing the conditions for production decision-making, and ensuring timely and accurate information transmission for decision-making.

Turnstiles

Automated turning aligned with turntable

For this project, to meet the requirement of handling same-size coil stacking on pallets, the turnstile can be programmed to inspect and rotate the arms. This prepares each arm for feeding in coils of the same size.

Down eneder

Automated pick-up and width check of steel coils

Through data sharing from the ERP system or via profit-bus, the coil can be automatically picked up according to width, eliminating the need for manual coil data input.

Automatic strapping machine

Steel Belt Strapping Machine

The strapping material used for coil binding is a steel belt.

Weight station

Weighing and data transmission

Coil data can be transferred to the printing and ERP systems for online label printing and application.

Printing station

Label Printer

Data generated from the packing line or shared from the ERP system can be printed and automatically applied to the surface of the steel coil.

Wrapping machine

Single-pass multi-layer wrapping

In the wrapping machine, a second layer of packing material is applied as needed. This outer layer secures the ancillary package in place and further protects the inner airtight film layer. Any handling damage is limited to the outer layer, while the inner layer remains intact, thereby keeping the coil sealed and protected due to the ancillary material sandwiched between the two layers.

Stacking machine

Precise Coil Stacking

With centering at the stacking position, this arm-type stacking machine can pick up and shift the steel coil precisely within 0-3mm on the pallet.

Coil pallet Turntable

For pallet collection and distribution

The turntable gathers the coils and rotates the pallet for coil stacking based on the stacking formula setting. Each pallet station can be set to receive a specific coil size. There's also an automatic indication for coil pallet unloading once the coil number reaches the set limit.

The solution for making the coil handling and packing in a pipe line

Offering Tailored Solutions for Various Loads

If you're unsure about the functions needed in a coil packaging line, the following solution diagram can guide you to understand the typical requirements of a slitting center. Alongside strapping and wrapping, there are stations for weighing, labeling, coil centering, and automatic timber feeding...

D. COLD ROLL COIL HANDLING AND PACKAGING LINE

The modern coil packing factory

14 years experience

Cold Roll Steel Coil

Packaging Line

Specifications

Coil Storage

Buffering for packing

This is the coil buffering area designed to receive the coil and manage packaging time, coil handling, or troubleshoot machine issues...

Automatic Master coil Wrapper

Coil eye through wrapping

This orbital wrapper uses shuttles that carry packing material for through-eye wrapping. It can handle Cold roll coils with a Max. OD of 2500mm, Width of 2200mm, Weight of 35T. Packing materials: VCI film, Paper, HDPE...

OD Covering Machine

Feeding and cutting

Two primary packing materials covering the steel coil OD are corrugated paper, plastic sheet, or steel sheet. After feeding the material, it will be cut to fit the coil OD. The packing material head & tail are connected by glue or tape.

ID&OD Protector

Corner Protector

This is one of the most challenging packing processes to automate. For the automatic solution, it usually requires a robot. Most companies opt for manual corner protector insertion.

Circumferential Strapping machine

OD strapping

This machine straps the steel coil at its OD with a steel belt or PET, according to the number setting.

Radial Strapping Machine

ID strapping

This machine straps the steel coil through its ID with a steel belt or PET, according to the number setting.

Auxiliary Equipment

Per requiremetn

The equipment varies based on the packaging goal and the function of the packing line.

Automation Control System

Industry PC control

Automation development for ERP and MES connection. FHOPE providing the level 1 to level 3 control system.

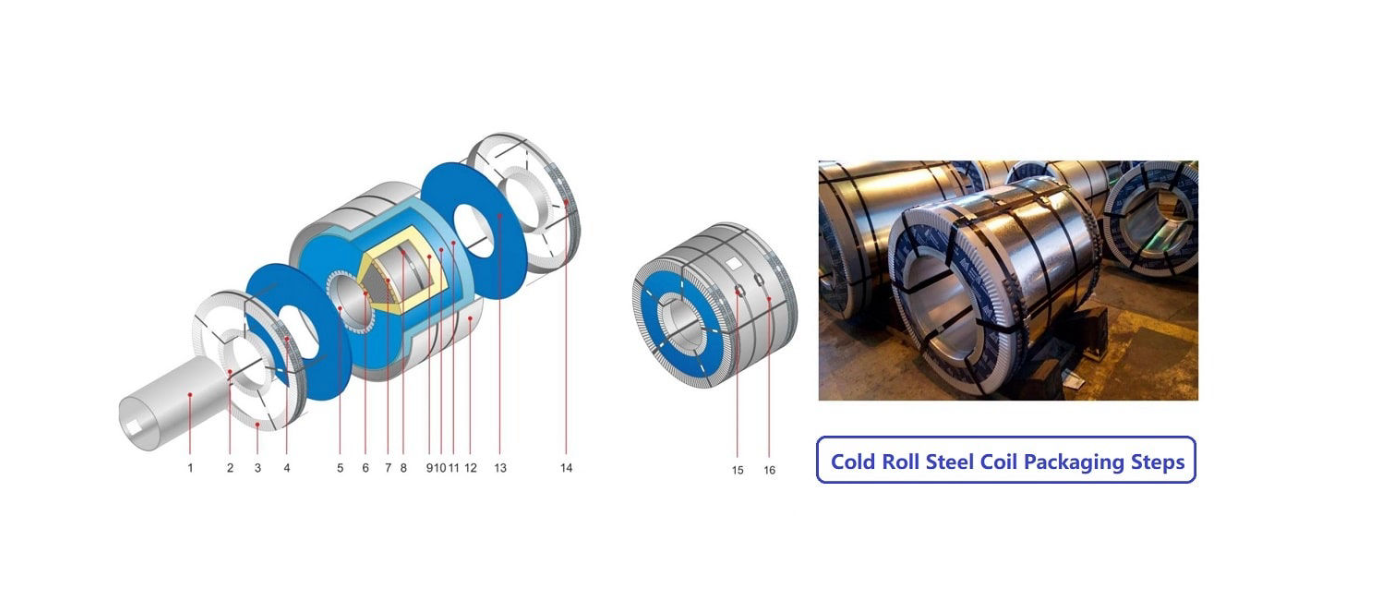

| 1.ID hole protector | 2. ID steel edge protector | 3. OD steel edge protector | 4. OD edge protector strapping | 5-6. ID cardboard protector |

| 7. OD cardboard protector | 8. Cold roll steel coil OD strapping | 9. VCI paper covering | 10. VCI film stretch wrapping | 11. Cardboard OD covering |

| 12. Steel sheet OD covering | 13. Side cover | 14. OD Edge protector | 15. Circumference coil strapping | 16. Radial coil strapping |

The solution for making the coil handling and packing in a pipe line

Offering Tailored Solutions for Various Loads

The ancillary packaging can also be utilized. This cold roll coil packaging might encompass outside diameter protectors, inside diameter protectors, side wall protectors or belly wrap materials. These materials can be integrated into the system for automatic application or can be manually applied.

E. More Special Solutions Can Be Option For Coil Packing Line

Vertical coil packing line, Economic coil packing system, auxiliary equipment very from projects.

By Machine - Identify the perfect solution for your requirements by choosing the kind of machine you need. The functions of the coil packing line can be customized.

By Industry - Discover the ideal solution for your coil packaging requirements by selecting your industry or market segment, such as copper, aluminum, etc.

More coil packaging information

The flow direction and layout are modifiable to fit the available space and coil handling exit.

The speed of Automatic coil packing machines is significantly faster than manual methods, making them the perfect equipment for projects requiring minimal space and cost, yet needing higher production rates.

FEATURE & ADVANTAGE

Safety

To substitute manual labor and prevent work-related injuries

Easy Operation

Full operation possible with unskilled personnel

Reliable

Complies with EU standards in electrical and mechanical aspects, requiring no maintenance

Get your best coil packing solution

More Information

Beyond the robust features already outlined, our systems offer additional capabilities: reliable process control, measurement data processing, clear visualization of statuses and processes, secure data archiving, and comprehensive diagnostics., andSiemens standard-compliant PLCs for reliable process control....

5. LEVEL 1: BASIC AUTOMATION ENVIRONMENT

Control system should enable in a reliable way:

➢ Process control

➢ Processing of measurement data

➢ Visualization of statuses and processes

➢ Data archiving

➢ Recording of any selected input signals or secondary signals generated in the system

➢ Diagnostics: alarms, warnings, operator events, breakdowns of industrial network, malfunction

of servers and operator stations

5.1. PLCs

Preferred standard for PLCs in AMP are Siemens S7-1500 PLCs (process line PLCs) and S7-1200

(in case of package installations). Selection of PLC series is done after agreement with AIM. For

scattered stations Siemens ET 200MP HF or ET 200SP HF is a standard solution.

It is recommended to use modules offering Shared Device functionality. Use of any other scattered

stations only upon agreement with AIM. Supplier should ensure unification i.e. use one type of

CPU, CP, PS for each series. Version of utility software, Simatic Manager or TIA Portal, should be

agreed with AMP. Allowable size of work memory utilization in PLC is 60%. Maximum time of

OB1 cycle is 150ms.

All PLCs should be in one multi-project, if possible, together with HMI projects. In case of Simatic

Manager (PLC) or TIA Portal (HMI) software, Device Proxy functionality should be used.

Programs in PLCs should be written according to strictly defined rules and criteria, and use

common library. Requirements and rules should be agreed on during initial design phase with

AIM employees.

All PLCs should be available from engineer station, including configurable network devices,

measuring and operating elements if it is possible to connect them to network and manage

them using PC/WWW application.

Contractor will supply source codes and documentation of all libraries used. It means that there

should be no element of the system for which the source codes are not provided, excluding

standard Siemens library blocks. Source codes should be written in a clear way with comments

in English and/or in Polish. Expectations to this requirement should be discussed during

negotiations.

PLCs should have automatic backup of modified parameters (e.g. process settings, regulators,

alarm thresholds, etc.) so that CPU starts-up with current parameters after restart or reset.

System should enable its easy expansion by adding new modules or stations, devices.

Technical requirements of access devices:

- access ports using 10/100/1000 RJ45,

- density of access ports should be from 8 to 12, 24 and 48 (to be agreed on),

- at least 2 ports 1G SFP, SFP+ or XFP,

- support of SPAN and RSPAN protocol or similar (same principal of operation),

- all ports must be active i.e. must be ready to use without additional licenses,

- all the above mentioned ports must work at full speed without over-subscription,

- support for POE is optional (upon agreement)

o must be compatible with PoE+ and supply at least 350W power for connected devices

o in case of version with the lowest density of ports it must be compatible with POE+ and

supply power to at least half of the access ports - support of 802.1X MAB protocol,

- support of filtering by MAC address,

- support of G.8032 protocol,

- support of the following spanning-tree protocols: RSTP, MSTP, VSTP or equivalent,

- support of 802.3ad (LACP) protocol,

- should enable correct transfer of PROFINET frames,

- support of 802.1q, security mechanisms (DAI, IP Source guard, DHCP Snooping, DHCP option 82, etc.).

Detailed requirements for access devices, enterprise switch:

General requirements for the devices, which should:

- be covered by at least 36 months (optimum support period for the devices is 60 months) or

manufacturer's or partner's support. Update of software, replacement of damaged components and

support in trouble-shooting should be possible during the validity of service agreement, - the manufacturer cannot have had declared end-of-support for configuration of the device offered

by the supplier within the entire support period, - enable management using command line, access to the command line must be through a built-in

local console port, and remote access using SSHv2 protocol, - support SNMP v2 and v3 protocol,

- enable authentication using RADIUS, TACACS and local user base,

- support marking and matching of packets according to 802.1p or DSCP,

- enable queuing mechanisms with at least 8 queues per physical port,

- enable installation in 19" cabinet,

- enable use of optical modules supplied by a third party regardless of maintenance service

purchased, - support automatic backup of configuration after each change of configuration or on demand,

- support remote syslog server,

- optionally support monitoring of operating environment (temperature, supply voltage, etc.).