introduction:

Workplace safety is a key concern for businesses in various industries, regardless of the country, factory, or work environment.

FHOPE Packaging believes that ensuring the safety of workers has become more important in manufacturing environments involving heavy molds.

Therefore, improving workplace safety and efficiency is imperative, and one effective solution is to use a mold flipper.

In this article, FHOPE Packaging will explore the benefits of mold flippers with you and discuss what needs to be understood when implementing mold flippers in the workplace.

What is Mold Upenders?

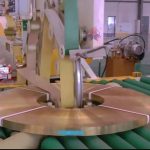

A mold flipper, also known as a mold flipper or reverser, is a machine specifically designed for safe handling and repositioning of heavy-duty molds used in manufacturing processes.

These machines are capable of rotating molds from a horizontal position to a vertical position, and vice versa, for easy maintenance, inspection, or transportation.

Strengthening workplace safety

Installing a mold flipper in the workplace can significantly improve safety through the following methods:

a. Reduce the time and frequency of manual handling:

The mold flipper eliminates the need for manual lifting and flipping of heavy molds, reduces the risk of back injuries and strains related to manual handling, and controls time costs.

In addition, the number of personnel operations has also been significantly reduced, and some customers may be able to independently perform mold flipping operations on their own

b. Controlled motion:

The flipping machine can precisely control the tilting process, which means that the mold is in a controlled state during the flipping process, ensuring smooth and controllable motion.

This minimizes the risk of accidents, such as molds slipping or falling during transportation.

c. Suitable for ergonomic design:

The design of the flipping machine takes into account ergonomics, with simple control panel buttons and a remote controller that can reach up to 5 meters, making it easier and safer for operators to load and unload molds.

They typically have adjustable control and safety functions to ensure operator comfort and minimize the risk of injury.

Improving efficiency and productivity

In addition to safety benefits, flipping machines also help improve workplace efficiency and productivity:

a. Time saving:

The mold flipper can quickly and efficiently reposition the mold, reducing downtime related to manual handling. This allows employees to focus on other tasks, thereby improving overall productivity.

b. Simplified maintenance:

With the mold flipper, accessing and maintaining molds becomes easier and more efficient. The ability to rotate molds simplifies the inspection, cleaning, and maintenance processes, minimizing production interruptions.

c. Best Space Utilization:

The mold flipper allows for vertical storage of molds, helping to maximize space utilization.

This frees up valuable floor space and enables better organization and flow within the workspace.

Implementation precautions

Before using a mold flipper in the workplace, please consider the following factors:

a. Equipment selection:

FHOPE packaging has a flipping expert who can select a mold flipper specifically designed for the user’s mold size and weight. Ensure that they have the necessary safety features and certifications to comply with industry standards.

b. Operator Training:

FHOPE Packaging will also provide comprehensive training on the safe operation of the flipping machine for users.

They should be familiar with control systems, security protocols, and appropriate load localization techniques. In this way, users have a practical plan for future use during the equipment preparation stage before purchasing

c. Equipment site space:

Users can communicate with FHOPE about the placement space and conditions of the equipment, which is conducive to establishing a regular maintenance and inspection plan for the flipping mechanism to ensure optimal performance and safety.

FHOPE Machinery will follow the manufacturer’s maintenance guidelines and promptly resolve any issues, such as equipping customers with perimeter guardrails and a grating sensing system.

Conclusion

The flipping machine provides many benefits for workplace safety, efficiency, and productivity.

By eliminating manual operation risks, providing controllable mobility, and simplifying maintenance processes, FHOPE packaging will help users create a favorable, safer, and more efficient work environment.

When considering the implementation of mold flipping devices, equipment options should be carefully evaluated, comprehensive operator training should be provided, and maintenance plans should be developed to maximize their advantages.

Prioritizing workplace safety through the use of mold flippers is a valuable investment that can bring long-term benefits to employees and businesses.