The manufacturing industry is undergoing a significant transformation with the advent of advanced technologies.

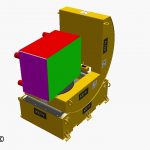

Mold upenders, also known as mold flippers or rotators, are one such innovation that is revolutionizing factory operations. These machines have become indispensable for manufacturers looking to streamline their processes and improve overall efficiency.

Here, we–FHOPE will explore seven key benefits of investing in a mold upender for your factory, highlighting how it can transform your manufacturing operations.

Enhanced Productivity

Investing in a mold upender can significantly enhance the productivity of your factory. These machines automate the process of handling heavy molds or dies, such as FPCT-40, FPCT-60 reducing the time and effort required for manual handling.

With quick and efficient mold changes, production downtime is minimized, allowing for increased output and improved overall efficiency.

Mold upenders enable smooth rotation and positioning of molds, ensuring precise alignment and reducing errors, thus boosting productivity in the manufacturing process.

Improved Ergonomics and Worker Safety

Worker safety and ergonomics are paramount in any manufacturing facility.

Mold upenders address these concerns by eliminating the need for manual lifting, reducing the risk of injuries and strains among workers.

These machines are equipped with safety features such as light barrier secure clamping mechanisms, and emergency stop buttons, ensuring a safe working environment. By promoting better ergonomics and minimizing physical strain, FHOPE’s mold upenders contribute to higher employee satisfaction and reduced absenteeism.

Streamlined Mold Handling

Mold upenders streamline the handling of molds or dies in factories. These machines provide mechanized lifting and rotating capabilities, eliminating the need for manual labor.

With precise control and adjustable rotation angles, mold upenders facilitate easy access for maintenance and cleaning. They also improve workflow efficiency by reducing the time required for mold changes.

The streamlined mold handling process ensures smoother production operations and allows for better utilization of resources.

Versatility and Adaptability

Investing in a mold upender offers versatility and adaptability to accommodate various manufacturing needs. These machines can handle molds or dies of different sizes, shapes, and weights, making them suitable for a wide range of products across industries.

FHOPE can provide the upender from 1-100 ton as manufacturing applications. Mold upenders can be customized to meet specific production requirements, providing flexibility in rotation angles and positioning.

This adaptability enables manufacturers to optimize their operations and cater to diverse customer demands.

Space Optimization

Space optimization is a crucial consideration in factory operations. Mold upenders are designed to occupy minimal floor space while providing maximum functionality.

These machines can be easily integrated into existing production lines or configured as standalone units.

By efficiently utilizing available space, mold upenders contribute to a more organized and structured factory layout, improving overall workflow and productivity.

Time and Cost Savings

Investing in a mold upender can lead to significant time and cost savings for manufacturers. The automation of mold handling reduces the reliance on manual labor, saving time and minimizing labor costs.

With faster mold changes and improved productivity, overall production time is reduced, enabling manufacturers to meet deadlines and fulfill orders promptly.

Additionally, the precise positioning and alignment capabilities of mold upenders reduce errors and material waste, resulting in cost savings and improved product quality.

Future-Proofing Your Operations

By investing in a mold upender, manufacturers future-proof their operations. These machines are aligned with the industry’s digital transformation and automation trends.

With the ability to integrate with other manufacturing technologies and systems, mold upenders ensure compatibility with future advancements.

Staying ahead of the curve in terms of technology adoption allows manufacturers to remain competitive, adapt to changing market demands, and position themselves as industry leaders.

Conclusion

Mold upenders manufactured by FHOPE are revolutionizing the manufacturing industry by streamlining mold handling, improving productivity, enhancing worker safety, and offering versatility and adaptability.

By investing in a mold upender, manufacturers can unlock numerous benefits, including improved ergonomics, streamlined operations, space optimization, time and cost savings, and future-proofing their operations.

Embracing this innovative technology is a strategic move that sets manufacturers on a path toward greater efficiency, productivity, and competitiveness in the evolving landscape of the manufacturing industry.