In the fast-paced world of manufacturing, optimizing production processes is crucial to stay competitive.

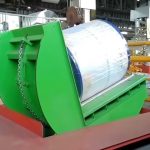

Mold upenders manufactured by FHOPE PACK, also known as mold flippers or rotators, hold the key to streamlining your production line and unlocking hidden efficiencies.

Now, we will uncover insider secrets about how mold upenders can transform your manufacturing operations.

From improving workflow to enhancing productivity, these innovative machines are the secret weapon that can take your production line to the next level.

Efficient Mold Handling

Mold upenders excel at streamlining mold handling, a critical aspect of any production line.

FHOPE’s mold upenders in model FPCT-02, FPCT-10, FPCT-20…can eliminate the need for manual lifting and rotating of heavy molds or dies, reducing the risk of injuries and strain on workers.

With their automated capabilities, mold upenders ensure smooth and precise positioning of molds, minimizing errors and improving overall efficiency.

By optimizing the mold handling process, production line bottlenecks are eliminated, resulting in faster turnaround times and increased output.

Seamless Integration

FHOPE’s Mold upender with roller conveyor, is integrated into your production line as a seamless process that can yield significant benefits.

It can be easily integrated with existing machinery and automation systems, allowing for a smooth flow of operations.

Mold upenders can be synchronized with other equipment, such as injection molding machines or die casting systems, ensuring a streamlined production process.

This integration eliminates manual intervention, reduces downtime, and maximizes the utilization of resources.

Quick Mold Changeovers

One of the biggest time-consuming factors in manufacturing is mold changeovers.

Mold upenders revolutionize this process by enabling quick and efficient mold swaps. With their precise rotation and positioning capabilities, FHOPE’s mold upenders facilitate rapid mold changeovers, minimizing downtime and increasing production uptime.

Manufacturers can switch between different molds or dies seamlessly, allowing for greater flexibility and responsiveness to customer demands.

Quick mold changeovers translate into higher productivity, reduced costs, and improved overall operational efficiency.

Improved Workflow and Space Optimization

Mold upenders optimize workflow and space utilization in the production line.

Fhope’s mold upender in model FPCT-05, FPCT-10 are designed to occupy minimal floor space while maximizing functionality.

By integrating mold upenders at strategic points in the production line, manufacturers can create a more efficient and organized workflow.

Mold upenders ensure smooth and efficient movement of molds, reducing congestion and improving overall material flow.

The optimized space utilization enables manufacturers to make the most of their available floor area, enhancing productivity and minimizing waste.

Enhanced Worker Safety and Ergonomics

Worker safety and ergonomics are paramount in any manufacturing environment.

Mold upenders prioritize these aspects by eliminating the need for manual lifting and rotating heavy molds. This reduces the risk of injuries and musculoskeletal disorders among workers.

Mold upenders in Model FPCT-50, FPCT-60 are equipped with safety features such as strong frame, electrical limit mechanisms, and emergency stop button, ensuring a safe working environment.

By promoting better ergonomics and minimizing physical strain, mold upenders improve employee well-being and morale.

Increased Productivity and Cost Savings

Implementing mold upenders in your production line can significantly boost productivity and result in cost savings.

By automating mold handling and reducing manual labor, manufacturers can achieve higher production rates and improved overall efficiency.

The streamlined workflow and quick mold changeovers minimize downtime, allowing for increased output and faster time-to-market.

Additionally, the improved accuracy and precision provided by mold upenders reduce material waste and enhance product quality, leading to cost savings and customer satisfaction.

Conclusion

Mold upenders hold the key to streamlining your production line and unlocking hidden efficiencies.

By optimizing mold handling, seamless integration, quick changeovers, workflow improvement, and enhancing worker safety, mold machines from FHOPE can revolutionize your manufacturing operations.

The increased productivity, cost savings, and improved efficiency resulting from the implementation of mold upenders can provide your business with a competitive edge in the fast-paced manufacturing industry.

Embrace these insider secrets and watch your production line reach new heights of success.