Title: Efficient Pallet Wrapping Machine for Secure Packaging | High Load Capacity | Industry Leading Manufacturer

Description:

Introduction:

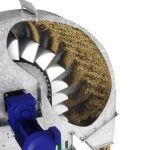

Welcome to our video showcasing the exceptional capabilities of our advanced pallet wrapping machine. Designed to meet the demands of modern packaging requirements, this highly efficient machine ensures secure and reliable packaging for all types of goods. With a focus on maximizing productivity and minimizing downtime, our pallet wrapping machine is a game-changer in the industry.

Video Content:

In this video, we explore the remarkable features and benefits of our pallet wrapping machine. With a maximum packaged goods height of 2.4m and a load capacity of 2 tons, our machine is built to handle even the most demanding packaging tasks. From fragile items to heavy-duty loads, this machine guarantees optimal stability and protection during transportation and storage.

Key Highlights:

1. Exceptional Load Capacity: Our pallet wrapping machine can effortlessly handle up to 2 tons of goods, ensuring secure packaging for even the heaviest loads.

2. Height Compatibility: With a generous packaged goods height of 2.4m, our machine accommodates various sizes and shapes, providing versatility for diverse packaging needs.

3. Advanced Wrapping Technology: Utilizing cutting-edge technology, our machine ensures precise and consistent wrapping, eliminating the risk of loose or unstable packaging.

4. Time and Cost Efficiency: By automating the packaging process, our machine significantly reduces labor costs and enhances overall productivity, allowing businesses to meet deadlines efficiently.

5. Durability and Reliability: Crafted with high-quality materials and precision engineering, our pallet wrapping machine guarantees long-lasting performance, minimizing maintenance requirements.

Operation Steps:

1. Secure the goods onto the pallet, ensuring they are properly aligned and stable.

2. Adjust the machine settings according to the specific requirements, such as wrapping tension and speed.

3. Activate the machine and observe as it wraps the pallet securely, ensuring a tight and protective packaging.

4. Once the wrapping process is complete, carefully remove the pallet and proceed with transportation or storage.

Call to Action:

If you found this video informative and valuable, we would appreciate your support by liking, subscribing, and sharing it with others who may benefit from our pallet wrapping machine. For more information and to explore our wide range of packaging solutions, please visit our website or contact our knowledgeable team.

Additional Tags and Keywords:

pallet wrapping machine, packaging machine, machinery, manufacturer, packing machine, industry, pallet packaging, secure packaging, automated packaging, load capacity, high load capacity, advanced wrapping technology, efficient packaging, packaging solutions

Hashtags:

#machine #machinery #manufacturer #packingmachine #packing #industry #packing #palletwrapping #securepackaging

Here’s a sample code for a tilter control for a Pallet Wrapping Machine:

“`

#include

// Define servo pin

const int servoPin = 9;

// Define tilt angles

const int tiltAngle1 = 0; // Initial position

const int tiltAngle2 = 90; // Tilted position

// Create servo object

Servo tiltServo;

void setup() {

// Attach servo to the pin

tiltServo.attach(servoPin);

// Set initial position

tiltServo.write(tiltAngle1);

// Initialize Serial communication

Serial.begin(9600);

}

void loop() {

// Check for input from user

if (Serial.available()) {

char command = Serial.read();

// Tilt the pallet

if (command == ‘T’) {

tiltPallet();

}

}

}

// Function to tilt the pallet

void tiltPallet() {

// Tilt to position 2

tiltServo.write(tiltAngle2);

delay(2000); // Wait for 2 seconds

// Tilt back to position 1

tiltServo.write(tiltAngle1);

delay(2000); // Wait for 2 seconds

Serial.println(“Pallet tilted!”);

}

“`

This code assumes that you have connected a servo motor to pin 9 of your Arduino. It listens for the character ‘T’ from the Serial Monitor and then tilts the pallet by moving the servo motor to position 2 (tilted position) for 2 seconds, and then back to position 1 (initial position) for another 2 seconds. It prints a message to the Serial Monitor after each tilt action. pallet wrapping machine

#Pallet #Wrapping #Machine