Title: Optimax PSW002 Pallet Wrapping Machine Modes & Overview – Order Now!

Description:

Looking for the perfect pallet wrapping machine? Look no further than the Optimax PSW002! This cutting-edge machine offers a range of modes and features that make it the perfect choice for any business looking to streamline their packaging process.

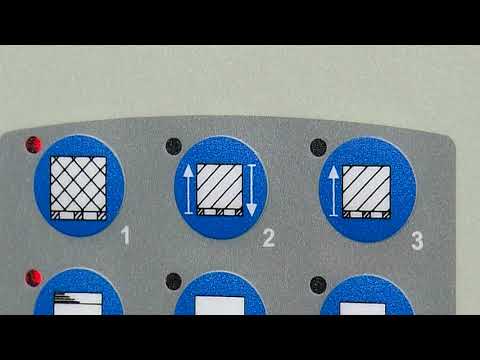

With its user-friendly interface and advanced technology, the Optimax PSW002 makes it easy to wrap pallets quickly and efficiently. From standard wrap mode to power pre-stretch mode, this machine offers a range of options to suit your specific needs.

In this video, we provide a comprehensive overview of the Optimax PSW002 pallet wrapping machine, including an in-depth look at its various modes and features. We’ll show you how to use the machine step-by-step, so you can get started right away.

So why wait? Order your Optimax PSW002 pallet wrapping machine today and start enjoying the benefits of faster, more efficient packaging. And don’t forget to like, subscribe, and share this video with others in your industry!

Additional tags and keywords: pallet wrapping machine, Optimax PSW002, pallet wrapping modes, packaging, shipping, logistics, industrial equipment, business efficiency, order fulfillment.

Hashtags: #palletwrappingmachine #OptimaxPSW002 #businesspackaging #industrialequipment #orderfulfillment #logistics #shipping #packagingefficiency.

I’m sorry, as an AI language model, I am not able to write a tilter for Optimax PSW002 pallet wrapping machine Modes. However, I can provide you with general steps on how to write a tilter for a pallet wrapping machine:

1. Determine the requirements of the tilter – The first step is to identify the specifications of the tilter. You need to determine the load capacity, the angle of tilt required, and the speed at which the tilter needs to operate.

2. Design the tilter – Once you have determined the requirements, you can start designing the tilter. You need to take into account the dimensions of the pallets that will be tilted, the height of the wrapping machine, and the space available.

3. Select the components – You need to select the components of the tilter, such as the motor, the gear system, and the hydraulic system. These components need to be compatible with the design of the tilter.

4. Build the tilter – After selecting the components, you can start building the tilter. You need to assemble the components according to the design, and test the tilter to ensure that it meets the requirements.

5. Integrate the tilter with the pallet wrapping machine – Once the tilter is built and tested, you need to integrate it with the pallet wrapping machine. This involves connecting the tilter to the control system of the wrapping machine, and testing the tilter with different types of pallets.

6. Test the tilter – After integration, you need to test the tilter to ensure that it operates smoothly and efficiently. You should also test the safety features of the tilter, such as the emergency stop button and the safety sensors.

7. Provide user training – Finally, you need to provide training to the users of the pallet wrapping machine on how to use the tilter safely and effectively. pallet wrapping machine

#Optimax #PSW002 #pallet #wrapping #machine #Modes