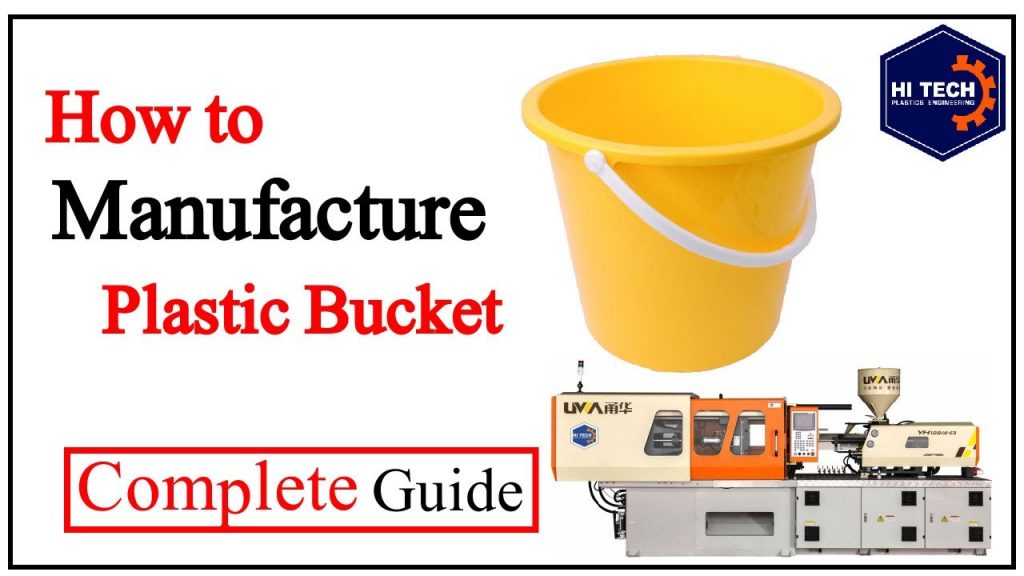

Check the plastic injection machine manufacturers for the best solutions in manufacturing plastic buckets. Hi-Tech Plastic Engineering provides a complete solution for plastic bucket production. In this video, we will show you how to manufacture plastic buckets using injection molding machines.

Introduction:

Plastic buckets are widely used in various industries for storing and transporting materials. They are durable, lightweight, and cost-effective. However, the process of manufacturing plastic buckets requires expertise and the right equipment. That’s where plastic injection machine manufacturers come in. They provide the necessary machinery and expertise to produce high-quality plastic buckets efficiently.

Manufacturing Process:

The manufacturing process of plastic buckets involves injection molding. This process is carried out using plastic injection machines. These machines use a combination of heat and pressure to melt the plastic material and inject it into a mold. Once the plastic material cools and solidifies, the mold is opened, and the finished plastic bucket is ejected.

Hi-Tech Plastic Engineering:

Hi-Tech Plastic Engineering is a leading manufacturer of plastic injection machines. They offer a complete solution for manufacturing plastic buckets. With their state-of-the-art machinery and expertise, they ensure high-quality production and efficient operation.

Advantages of Hi-Tech Plastic Engineering:

1. Quality Machinery: Hi-Tech Plastic Engineering provides top-of-the-line plastic injection machines that are designed for precision and reliability. Their machines are built to withstand the demands of high-volume production and deliver consistent results.

2. Cost-effective Solutions: By partnering with Hi-Tech Plastic Engineering, manufacturers can benefit from cost-effective solutions for plastic bucket production. Their machines are designed for maximum efficiency, reducing production costs and increasing profitability.

3. Expert Support: Hi-Tech Plastic Engineering offers comprehensive support to their customers. From initial setup to ongoing maintenance and troubleshooting, their team of experts is always ready to assist manufacturers in achieving optimal production results.

4. Customizable Options: Hi-Tech Plastic Engineering understands that different manufacturers have unique requirements. They offer customizable options for their plastic injection machines, allowing manufacturers to tailor the production process to their specific needs.

Conclusion:

Manufacturing plastic buckets requires the right equipment and expertise. Plastic injection machine manufacturers like Hi-Tech Plastic Engineering provide a complete solution for producing high-quality plastic buckets efficiently. By partnering with them, manufacturers can benefit from top-of-the-line machinery, cost-effective solutions, expert support, and customizable options.

Check the plastic injection machine manufacturers for the best production solution. Hi-Tech Plastic Engineering offers a complete solution for manufacturing plastic buckets. With their state-of-the-art machinery and expertise, they ensure high-quality production and efficient operation. Contact them now to learn more about their services and enhance your plastic bucket manufacturing process.

***Check the plastic injection machine manufacturers for the best production solution. Hi-Tech Plastic Engineering offers a complete solution for manufacturing plastic buckets. With their state-of-the-art machinery and expertise, they ensure high-quality production and efficient operation. Contact them now to learn more about their services and enhance your plastic bucket manufacturing process.*** Plastic Injection Machine

“Mastering Injection Molding: Crafting Plastic Buckets with Cutting-Edge Technology”