Check out the leading manufacturer for professional coil packing solutions here: [link]

Title: 8 Reasons Why You Should Be Using a Babyplast Micromolding Machine

Introduction:

In this episode of “Some Serious Engineering,” Gordon dives into the world of micromolding machines and specifically focuses on the Babyplast Micromolding Machine. As a sales engineer, Gordon understands the importance of using the right equipment for the job, and he believes that the Babyplast Micromolding Machine is a game-changer in the plastic injection industry. In this article, we will explore eight compelling reasons why you should consider using this innovative machine.

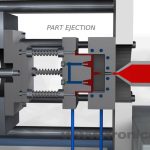

1. Unmatched Precision:

The Babyplast Micromolding Machine boasts an exceptional level of precision, allowing for the production of intricate and detailed plastic components. Its advanced technology ensures minimal part variations, resulting in high-quality end products.

2. Cost-Effective Solution:

With the Babyplast Micromolding Machine, manufacturers can reduce production costs significantly. Its compact design and efficient operation make it ideal for small-scale production, eliminating the need for expensive and bulky machinery.

3. Versatility:

This micromolding machine offers versatility like no other. It can handle a wide range of materials and produce parts with varying complexities. From medical devices to automotive components, the Babyplast Micromolding Machine can fulfill diverse manufacturing requirements.

4. Faster Time-to-Market:

In today’s fast-paced business environment, time is of the essence. The Babyplast Micromolding Machine enables rapid prototyping and short production cycles, allowing manufacturers to bring their products to market faster than ever before.

5. Energy Efficiency:

The Babyplast Micromolding Machine is designed with energy efficiency in mind. Its innovative technology minimizes power consumption, reducing environmental impact while saving on operational costs.

6. User-Friendly Interface:

Operating the Babyplast Micromolding Machine is a breeze, thanks to its intuitive user interface. With user-friendly controls and clear instructions, even inexperienced operators can quickly learn to use the machine effectively.

7. Reliability and Durability:

Manufacturers can rely on the Babyplast Micromolding Machine for consistent and reliable performance. Built with high-quality materials and precision engineering, this machine is designed to withstand the demands of continuous production.

8. Excellent After-Sales Support:

Babyplast takes pride in providing exceptional after-sales support to its customers. With a dedicated team of experts, they offer technical assistance, spare parts, and maintenance services, ensuring that your production line remains uninterrupted.

Conclusion:

The Babyplast Micromolding Machine is revolutionizing the plastic injection industry with its precision, cost-effectiveness, versatility, and user-friendly interface. Its ability to accelerate time-to-market and reduce energy consumption make it a compelling choice for manufacturers. With reliable performance and excellent after-sales support, Babyplast has established itself as a trusted name in the industry.

So, if you’re looking for a reliable micromolding machine that ticks all the boxes, look no further than the Babyplast Micromolding Machine. Take your plastic injection manufacturing to the next level and experience the numerous benefits it offers.

Check out the leading manufacturer for professional coil packing solutions here: [link] Plastic Injection Machine

“Unleashing the Potential: Discover the Advantages of Babyplast Micromolding Machines | Some Serious Engineering – Ep3 & Injection Machine Insights”