Title: Efficient Automatic Packing Line for Sale | Soap Bar and Laundry Soap Flow Wrapping Machinery

Description:

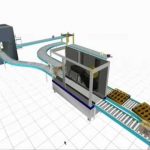

Welcome to our video showcasing the advanced Automatic Packing Line for Sale, featuring state-of-the-art Soap bar automatic packing Machine line and Laundry soap flow wrapping Machinery. This comprehensive and high-performance packaging solution is designed to streamline your production process and optimize efficiency. Watch this video to discover the key features, operation steps, and benefits of the Automatic Packing Line.

Introduction:

In this video, we present an innovative Automatic Packing Line for Sale that encompasses Soap bar automatic packing Machine line and Laundry soap flow wrapping Machinery. This cutting-edge solution is specifically designed to meet the packaging needs of soap manufacturers, ensuring a seamless and efficient production process.

Video Content:

1. Key Features:

– The Automatic Packing Line offers a fully automated packaging process, eliminating the need for manual intervention and enhancing productivity.

– It utilizes advanced technology to achieve precise and consistent packaging results, ensuring the highest quality standards.

– The Soap bar automatic packing Machine line efficiently handles soap bars, ensuring secure packaging and protection during transportation.

– The Laundry soap flow wrapping Machinery excels in wrapping laundry soap bars, providing a professional and appealing presentation.

2. Operation Steps:

– The video demonstrates the step-by-step process of the Automatic Packing Line, from soap bar loading to finished product packaging.

– It highlights the seamless integration of different machinery components, showcasing the smooth flow of operations.

– The precise and accurate movements of the machines guarantee efficient packaging with minimal wastage.

Call to Action:

If you found this video informative and inspiring, we encourage you to hit the like button, subscribe to our channel for more industry-related content, and share this video with your peers. Stay updated with the latest packaging innovations and solutions.

Additional Tags and Keywords:

Automatic Packing Line, Soap bar automatic packing Machine line, Laundry soap flow wrapping Machinery, foodpackingmachine, packing machine, flow packaging machine, BoxMotion408S, horizontal packing machine, soap packaging, soap bar packaging, soap manufacturing, soap production line, packaging efficiency.

Hashtags:

#AutomaticPackingLine #SoapPackaging #LaundrySoapWrapping #PackagingEfficiency #IndustryInnovations

Title: Soap Bar Automatic Packing Machine Line: Laundry Soap Flow Wrapping Machinery Tilter

Introduction:

The Soap Bar Automatic Packing Machine Line is an advanced solution for packaging laundry soap bars efficiently. This machinery integrates a tilter, which enhances the overall packaging process. In this article, we will explore the features and benefits of the Soap Bar Automatic Packing Machine Line with a tilter, highlighting its significance in the laundry soap flow wrapping industry.

1. Enhanced Efficiency:

The tilter integrated into the Soap Bar Automatic Packing Machine Line optimizes the packaging process by ensuring a smooth and continuous flow of soap bars. It intelligently adjusts the position of the soap bars to align them perfectly for wrapping, eliminating any potential jams or disruptions during the process.

2. Precise Positioning:

The tilter component is equipped with advanced sensors and controls that accurately detect the position of each soap bar. This ensures precise alignment and positioning of the soap bars, ensuring consistent and uniform packaging results.

3. Versatile Compatibility:

The tilter is designed to accommodate soap bars of various shapes and sizes, making it suitable for a wide range of laundry soap products. Its adjustable settings allow for seamless integration into existing packaging lines, providing flexibility to manufacturers.

4. Reduced Downtime:

By eliminating jams and disruptions, the tilter significantly reduces downtime during the packaging process. It minimizes the need for manual intervention, saving valuable time and labor costs for manufacturers. This increased efficiency contributes to higher productivity and faster turnaround times.

5. Improved Packaging Quality:

The tilter ensures that each soap bar is perfectly positioned for wrapping, resulting in impeccable packaging quality. This reduces the risk of damaged or misaligned packaging, enhancing the overall appearance and market appeal of the laundry soap products.

6. User-Friendly Interface:

The Soap Bar Automatic Packing Machine Line with a tilter features a user-friendly interface that allows operators to easily control and monitor the packaging process. The intuitive controls enable quick adjustments and troubleshooting, ensuring smooth operation and minimal operator training.

7. Cost-Effective Solution:

By increasing efficiency, reducing downtime, and improving packaging quality, the Soap Bar Automatic Packing Machine Line with a tilter offers a cost-effective solution for laundry soap manufacturers. It streamlines production, reduces waste, and lowers labor costs, ultimately maximizing profitability.

Conclusion:

The integration of a tilter into the Soap Bar Automatic Packing Machine Line revolutionizes the packaging process in the laundry soap industry. With its enhanced efficiency, precise positioning, and versatile compatibility, this machinery provides a reliable and cost-effective solution for manufacturers. By investing in this advanced technology, laundry soap producers can optimize their production capabilities, enhance product quality, and gain a competitive edge in the market. coil packing line

#Soap #bar #automatic #packing #Machine #line #Laundry #soap #flow #wrapping #Machinery