Title: “Efficient and Reliable Automatic Packing Line Solutions for Bearing Manufacturers”

Description:

Welcome to our comprehensive video on Automatic Packing Line Manufacturers, showcasing top-of-the-line machinery for the bearing industry. In this video, we highlight the Automatic Bearing Packing Line, Bearing Flow Wrapping Machine, Bearing Carton Box Packing Machine, and Bearing Cartoning Machine. These cutting-edge machines offer complete full automation, ensuring seamless and efficient packaging processes.

Introduction:

In this video, we present an in-depth overview of Automatic Packing Line Manufacturers, specifically focusing on the advanced machinery designed for bearing packaging. Whether you are a small-scale producer or a large manufacturing facility, our solutions cater to your specific needs, streamlining your operations and enhancing productivity.

Video Content:

1. Automatic Bearing Packing Line: Discover how our state-of-the-art packing line optimizes the packaging process for bearings, ensuring accuracy, speed, and precision. We discuss the key features and benefits of this system, highlighting its ability to handle various bearing sizes and packaging requirements seamlessly.

2. Bearing Flow Wrapping Machine: Learn about our innovative flow wrapping machine, designed to wrap bearings securely and professionally. We delve into the machine’s capabilities, highlighting its flexibility in accommodating different bearing dimensions and ensuring a neat, presentable finished product.

3. Bearing Carton Box Packing Machine: Explore our efficient carton box packing machine, which automates the process of placing bearings into carton boxes. We showcase its user-friendly interface and discuss its ability to handle different box sizes, reduce manual labor, and improve packaging consistency.

4. Bearing Cartoning Machine: Witness the power of our advanced cartoning machine, designed to automatically load bearings into cartons with precision and speed. We emphasize its versatility in handling various bearing types and sizes, while ensuring efficient and reliable packaging.

Call to Action:

If you found this video informative and helpful, please consider liking, subscribing, and sharing it with others in the bearing industry. Stay updated with the latest advancements in automatic packing solutions by subscribing to our channel.

Additional Tags and Keywords: Automatic Packing Line, Bearing Packaging, Flow Wrapping Machine, Carton Box Packing Machine, Cartoning Machine, Automation, Efficiency, Manufacturing Industry, Productivity.

Hashtags: #AutomaticPackingLine #BearingPackaging #EfficientMachinery #Automation #Manufacturing #Productivity

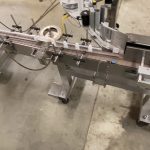

Here is a sample tilter for an automatic bearing packing line that includes a bearing flow wrapping machine and a bearing carton box packing machine:

1. Start by ensuring that all safety measures are in place and that the machines are properly connected and powered on.

2. Set up the bearing flow wrapping machine by adjusting the conveyor speed and the wrapping material tension to the desired specifications.

3. Place the bearings onto the input conveyor of the flow wrapping machine. Ensure that the bearings are properly aligned and evenly spaced to avoid any jams or blockages.

4. Activate the flow wrapping machine and monitor the wrapping process to ensure that each bearing is wrapped correctly and securely. Adjust the machine settings if necessary.

5. Once the bearings are wrapped, they will be discharged onto the output conveyor of the flow wrapping machine. Ensure that the conveyor is clear and ready to receive the wrapped bearings.

6. Set up the bearing carton box packing machine by adjusting the box size and the packing mechanism to accommodate the wrapped bearings.

7. Place the empty carton boxes onto the input conveyor of the carton box packing machine. Ensure that the boxes are properly positioned and aligned for accurate packing.

8. Activate the carton box packing machine and monitor the packing process to ensure that each box is filled with the correct number of wrapped bearings. Adjust the machine settings if necessary.

9. Once the boxes are packed with the wrapped bearings, they will be discharged onto the output conveyor of the carton box packing machine. Ensure that the conveyor is clear and ready to receive the packed boxes.

10. Continue the process until all the bearings have been wrapped and packed into the carton boxes. Regularly check the machines for any issues or malfunctions and address them promptly.

11. Once the packing process is complete, perform a final quality check on the packed boxes to ensure that they meet the required standards.

12. Remove the packed boxes from the output conveyor and prepare them for storage or shipment.

13. Clean and maintain the machines regularly to ensure their optimal performance and longevity.

Note: The tilter instructions provided above assume a basic understanding of the operation and setup of the mentioned machines. Always refer to the manufacturer’s manuals and guidelines for detailed instructions specific to your equipment. coil packing line

#Automatic #Bearing #Packing #Line #Bearing #Flow #Wrapping #Machine #Bearing #Carton #Box #Packing #Machine