Check out our website for the best coil packing solutions available in the market today!

—

Title: The Ultimate Guide to Semi-Automatic Plastic Injection Machines

Introduction:

Are you looking for an efficient and reliable solution for your plastic injection molding needs? Look no further! In this video, we will explore the world of semi-automatic plastic injection machines and how they can revolutionize your manufacturing process.

Section 1: Understanding Semi-Automatic Plastic Injection Machines

Before we delve into the benefits and features of semi-automatic plastic injection machines, let’s first understand what they are and how they work.

1.1 What are Semi-Automatic Plastic Injection Machines?

Semi-automatic plastic injection machines are advanced manufacturing tools designed to produce high-quality plastic products. Unlike fully automatic machines, these machines require manual intervention during certain stages of the injection molding process.

1.2 How do Semi-Automatic Plastic Injection Machines Work?

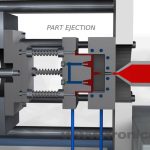

These machines consist of a mold, an injection unit, and a clamping unit. The mold is filled with molten plastic material, which is injected into the mold cavity through the injection unit. The clamping unit then holds the mold together while the plastic cools and solidifies. Once the plastic has hardened, the mold is opened, and the finished product is ejected.

Section 2: Advantages of Semi-Automatic Plastic Injection Machines

Now that we understand the basics of semi-automatic plastic injection machines, let’s explore the advantages they offer over other types of machines.

2.1 Cost-Effective Solution

Semi-automatic machines are a cost-effective alternative to fully automatic machines. They require less initial investment and have lower operating costs. This makes them an ideal choice for small to medium-sized businesses looking to optimize their production process without breaking the bank.

2.2 Greater Control and Flexibility

With semi-automatic machines, operators have greater control over the injection molding process. They can adjust various parameters such as injection speed, pressure, and temperature, ensuring optimal results for each product. This level of control allows for greater flexibility in manufacturing different types of plastic products.

2.3 Suitable for Small Batch Production

Semi-automatic machines are perfect for small batch production runs. They offer quick setup times and easy mold changes, enabling manufacturers to produce a wide range of products in smaller quantities. This flexibility is especially beneficial for businesses catering to niche markets or dealing with seasonal demands.

Section 3: Case Study – Transforming Plastic Molding with Semi-Automatic Machines

To further highlight the effectiveness of semi-automatic plastic injection machines, let’s look at a real-life case study.

3.1 Company X: Revolutionizing Plastic Molding

Company X, a leading manufacturer in the plastic molding industry, was facing challenges in meeting customer demands due to their existing fully automatic machines. They decided to invest in semi-automatic plastic injection machines to streamline their production process.

By incorporating semi-automatic machines, Company X was able to:

– Reduce production costs by 30%

– Increase production efficiency by 25%

– Improve product quality and consistency

– Meet customer demands more effectively

Section 4: The Future of Semi-Automatic Plastic Injection Machines

4.1 Advancements in Technology

As technology continues to evolve, semi-automatic plastic injection machines are becoming more advanced and efficient. Manufacturers are integrating features like robotic automation, real-time monitoring systems, and smart controls to enhance productivity and reduce human error.

4.2 Growing Demand in Emerging Markets

The demand for semi-automatic plastic injection machines is rapidly increasing in emerging markets. Countries like Morbi, Kanpur, Bihar, Bagalur, and Chapra are witnessing a rise in manufacturing activities, creating a need for reliable and cost-effective injection molding solutions.

Conclusion:

Semi-automatic plastic injection machines offer a cost-effective and efficient solution for businesses in the plastic molding industry. With their flexibility, control, and suitability for small batch production, these machines are transforming the way manufacturers produce plastic products.

So, if you’re looking to optimize your production process and stay ahead of the competition, consider investing in a semi-automatic plastic injection machine. Revolutionize your manufacturing process and unlock new possibilities for your business today!

Check out our website for the best coil packing solutions available in the market today! Plastic Injection Machine

“Semi-Automatic Vertical Plastic Moulding Machine: Boosting Efficiency in Morbi, Kanpur, Bihar, Bagalur, Chapra, and Beyond”