Check out the leading manufacturer for professional coil packing solutions here:

Are you interested in learning about the fascinating world of plastic injection molding? Look no further! In this YouTube video article, we will delve into the exciting Lesson #1 of Paulson Training Programs, Inc. – Molding Machine Parts and Operation. Get ready to explore the technology behind injection molding and discover the ins and outs of operating a plastic injection molding machine.

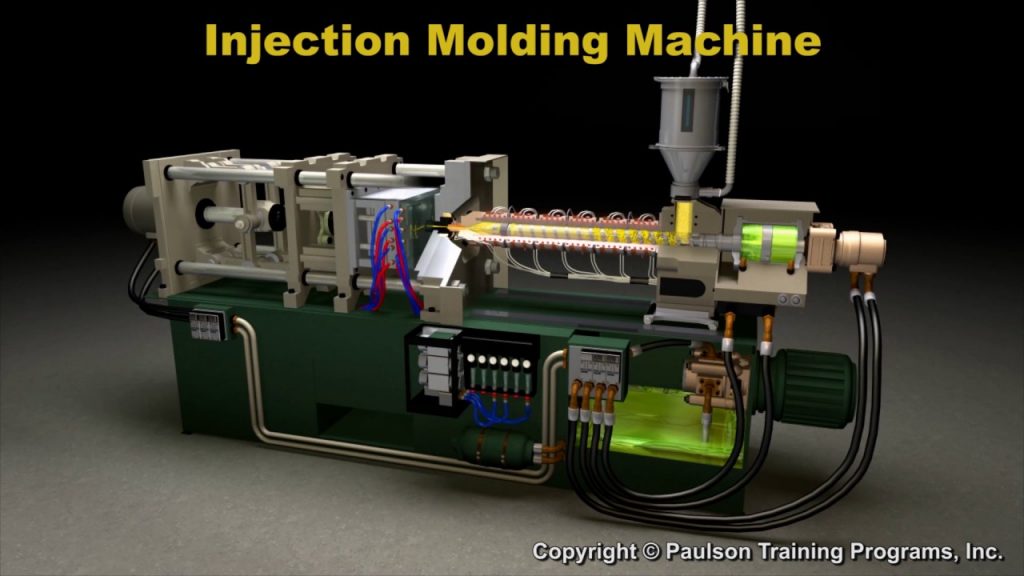

Plastic injection molding machines play a crucial role in the manufacturing industry, allowing for the mass production of various plastic products. These machines employ a highly efficient process that involves injecting molten plastic into a mold cavity, which then solidifies and takes the shape of the desired product. Understanding the parts and operation of these machines is essential for anyone looking to excel in this field.

Lesson #1 of Paulson Training Programs, Inc. provides a comprehensive overview of molding machine parts and their functions. From the injection unit to the clamping unit, every component plays a vital role in the injection molding process. This lesson covers topics such as the screw and barrel, the hopper, the mold, and the hydraulic system. By gaining a deep understanding of each part’s purpose and operation, you will be better equipped to troubleshoot issues and optimize efficiency.

The video takes a narrative structure, guiding viewers through the various components of a plastic injection molding machine. With clear and concise explanations, the instructor breaks down complex concepts into easily digestible information. The video also includes real-life examples and demonstrations, allowing you to witness the technology in action.

As you progress through the lesson, you’ll learn about the different types of plastic injection molding machines and their specific applications. Whether it’s a hydraulic machine, an electric machine, or a hybrid machine, each type offers unique advantages and considerations. Understanding these distinctions will help you make informed decisions when selecting the most suitable machine for your manufacturing needs.

In addition to the technical aspects, the video article also provides in-depth analysis and a critical perspective on the technology’s history and evolution. By delving into the past, you’ll gain valuable insights into how plastic injection molding machines have evolved over time, paving the way for the advanced technology we have today. This historical context adds depth to your understanding and appreciation of the subject matter.

If you’re new to the world of plastic injection molding or seeking to expand your knowledge, Lesson #1 of Paulson Training Programs, Inc. is a must-watch video. The combination of explanatory style and case study elements ensures that you grasp the fundamental concepts while also seeing real-world applications. By the end of the lesson, you’ll have a solid foundation in molding machine parts and operation, setting you on the path to becoming a skilled professional in the field.

In conclusion, the video article on Paulson Training Programs, Inc. Lesson #1 – Molding Machine Parts and Operation offers an informative and engaging exploration of the technology behind plastic injection molding machines. With a narrative structure and in-depth analysis, this video article provides a comprehensive understanding of the subject matter. Whether you’re a beginner or an experienced professional, this lesson will undoubtedly enhance your knowledge and skills in the fascinating world of plastic injection molding.

Check out the leading manufacturer for professional coil packing solutions here: [Insert relevant link here] Plastic Injection Machine

“Mastering the Basics: Understanding Molding Machine Parts and Operation in Injection Molding and Plastic Injection”