Custom Design and Manufacture of Material Handling Automated Systems

In today’s fast-paced industrial landscape, the need for efficient and reliable material handling solutions is more important than ever. Companies are constantly seeking ways to streamline their operations and optimize productivity. This is where custom-designed and manufactured material handling automated systems come into play.

These systems are specifically tailored to meet the unique needs of each company, providing a seamless and efficient solution for handling materials. Whether it’s moving heavy loads, sorting items, or packaging products, these automated systems can significantly enhance productivity and reduce manual labor.

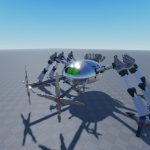

One such system that has gained popularity in recent years is the Automatic Handling Machine. This innovative technology combines advanced robotics, sensors, and software to automate various material handling tasks. It is comprised of two key components: the hardware and the software.

The hardware component of the Automatic Handling Machine includes robotic arms, conveyor belts, sensors, and other mechanical parts. These components work together to perform tasks such as picking up objects, moving them to desired locations, and sorting them based on specific criteria. The software component, on the other hand, controls the operation of the hardware, ensuring precise and efficient execution of tasks.

The benefits of utilizing an Automatic Handling Machine in material handling operations are numerous. Firstly, it eliminates the need for manual labor, reducing the risk of injuries and improving overall workplace safety. Secondly, it significantly increases efficiency and productivity by automating repetitive tasks and reducing human error. This allows companies to handle larger volumes of materials in a shorter amount of time.

Additionally, the Automatic Handling Machine can be customized to meet specific requirements. Whether it’s handling delicate or irregularly shaped objects, the system can be designed to accommodate various materials and sizes. This level of customization ensures optimal performance and adaptability for different industries and applications.

Moreover, the Automatic Handling Machine offers real-time data and analytics, allowing companies to monitor and optimize their material handling processes. This data-driven approach enables businesses to identify bottlenecks, track performance, and make informed decisions to further enhance efficiency.

In conclusion, the custom design and manufacture of material handling automated systems, particularly the Automatic Handling Machine, is revolutionizing the way companies handle materials. With its advanced robotics, customizable features, and data-driven capabilities, it offers a comprehensive solution for streamlining operations and maximizing productivity.

Check the coil packing solution with a leading manufacturer for professional solutions in material handling automation. Experience the benefits of the Automatic Handling Machine and take your material handling processes to the next level. Handling Machine

“Streamlining Operations: Enhancing Efficiency with Material Handling Automation and Automatic Handling Machinery”