So, you want to make your own products out of recycled plastic? Props to you! Recycling plastic is not only a great way to reduce waste, but it also allows you to create unique and sustainable products. But before you can start turning your plastic waste into treasures, you need to understand what an Injection Mould is and how it works with a Plastic Injection Molding Machine.

Injection moulding is a manufacturing process that involves injecting molten plastic material into a mould to create a desired shape. This process is widely used in various industries, including automotive, electronics, packaging, and more. The Plastic Injection Molding Machine is the equipment used to perform this process.

Now, let’s dive into the details of what you need to know about Injection Moulds and Plastic Injection Molding Machines.

Injection Moulds:

An Injection Mould is a custom-made tool that is used to shape the plastic material during the injection moulding process. It is typically made of steel or aluminum and consists of two halves, the core and the cavity. The core creates the internal features of the product, while the cavity forms the external features. The molten plastic material is injected into the cavity, and once it cools and solidifies, the mould is opened, and the finished product is ejected.

To create an Injection Mould, you need to consider various factors, such as the design of the product, the type of plastic material to be used, and the desired production volume. The mould design must be precise and optimized for efficient production, ensuring that the plastic material flows smoothly and evenly throughout the cavity. This helps to avoid defects such as voids, warping, or sink marks in the final product.

Plastic Injection Molding Machines:

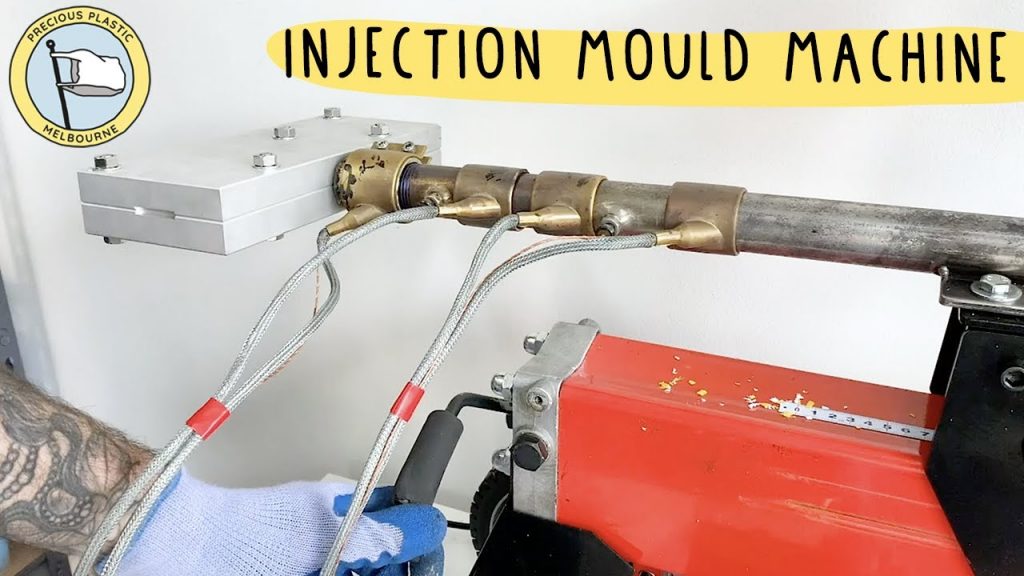

A Plastic Injection Molding Machine is the key equipment used to perform the injection moulding process. It consists of a hopper, where the plastic material is fed, a heating unit, which melts the plastic, and an injection unit, which injects the molten plastic into the mould. The machine also includes a clamping unit, which holds the mould securely in place during the injection process.

When choosing a Plastic Injection Molding Machine, you need to consider factors such as the machine’s clamping force, shot size, and injection pressure. The clamping force determines the machine’s ability to hold the mould closed during injection, while the shot size refers to the maximum amount of plastic material that can be injected in one cycle. The injection pressure affects the flow and packing of the plastic material inside the mould.

Precious Plastic Melbourne:

If you’re looking for more information and resources on Injection Molding and Plastic Moulding Machines, check out Precious Plastic Melbourne. They provide comprehensive guides, tutorials, and support for individuals interested in recycling plastic and creating their own products. Their website offers valuable insights into the plastic recycling process and showcases innovative projects that promote sustainability.

In conclusion, if you’re passionate about recycling plastic and creating your own products, understanding the role of Injection Moulds and Plastic Injection Molding Machines is essential. These tools and machines enable you to transform plastic waste into functional and environmentally-friendly products. So, get ready to embark on your recycling journey and start making a positive impact on the environment!

Check the coil packing solution with leading manufacturers for the professional solution just here. Plastic Injection Machine

“Master the Art of Injection Moulding: Simplifying the Process with Precious Plastic Melbourne and an Efficient Plastic Injection Molding Machine”