If you are in the logistics industry, you are probably aware of the numerous challenges that come with managing a warehouse. From inventory management to order fulfillment, every process needs to be efficient and accurate to ensure smooth operations.

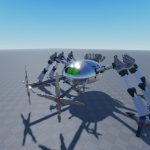

One solution that has gained immense popularity in recent years is the automation of warehouse processes. By using automated guided vehicles (AGVs) and automatic handling machines, companies can significantly enhance their efficiency and productivity.

In this YouTube video, we will explore the benefits of implementing automation in the warehouse and how automatic handling machines, specifically, play a crucial role in streamlining operations.

Automatic handling machines are designed to handle various tasks in the warehouse, such as picking, packing, and sorting. These machines use advanced technology and robotic arms to perform these tasks with precision and speed, eliminating the need for manual labor.

One of the key advantages of using automatic handling machines is the reduction in errors. With manual handling, there is always a chance of human error, leading to incorrect orders or misplaced items. However, with automated machines, the chances of errors are significantly reduced, ensuring accurate order fulfillment and inventory management.

Another benefit of using automatic handling machines is the increase in productivity. These machines can work round the clock without the need for breaks or rest, resulting in a higher output in a shorter amount of time. This increased productivity translates to faster order processing and improved customer satisfaction.

Furthermore, automatic handling machines also contribute to a safer working environment. By taking over repetitive and physically demanding tasks, they minimize the risk of injuries to warehouse workers. This not only ensures the well-being of employees but also reduces the company’s liability for workplace accidents.

In addition to automatic handling machines, AGVs also play a crucial role in warehouse automation. These vehicles are equipped with sensors and software that enable them to navigate through the warehouse without human intervention. They can transport goods from one location to another, eliminating the need for manual labor and reducing the time taken for material handling.

AGVs offer several advantages, including increased efficiency, reduced operating costs, and improved inventory accuracy. They can optimize the use of space within the warehouse, maximizing storage capacity and minimizing wasted space. With their ability to communicate and coordinate with other machines, AGVs can also enhance the overall efficiency of the warehouse, reducing the time taken for material flow.

As technology continues to advance, warehouse automation is becoming more prevalent in the logistics industry. Companies are realizing the numerous benefits that automation brings, from increased productivity to improved accuracy.

If you are looking to streamline your warehouse operations and enhance your efficiency, it is essential to consider implementing automatic handling machines and AGVs. These technologies can revolutionize the way you manage your warehouse, leading to significant cost savings and improved customer satisfaction.

Check out our video to learn more about the advantages of warehouse automation and how automatic handling machines and AGVs can transform your operations. Don’t miss out on this opportunity to revolutionize your warehouse management!

Check the coil packing solution with a leading manufacturer for the professional solution right here. Handling Machine

“Revolutionizing Warehouse Operations: Enhancing Efficiency and Accuracy with Automated Guided Vehicles and Storage & Retrieval Machines”