Check out the leading manufacturer for a professional coil packing solution right here:

—

Title: Building the Future: LEGO Bricks and Industrial Robot Arms Unite

Introduction:

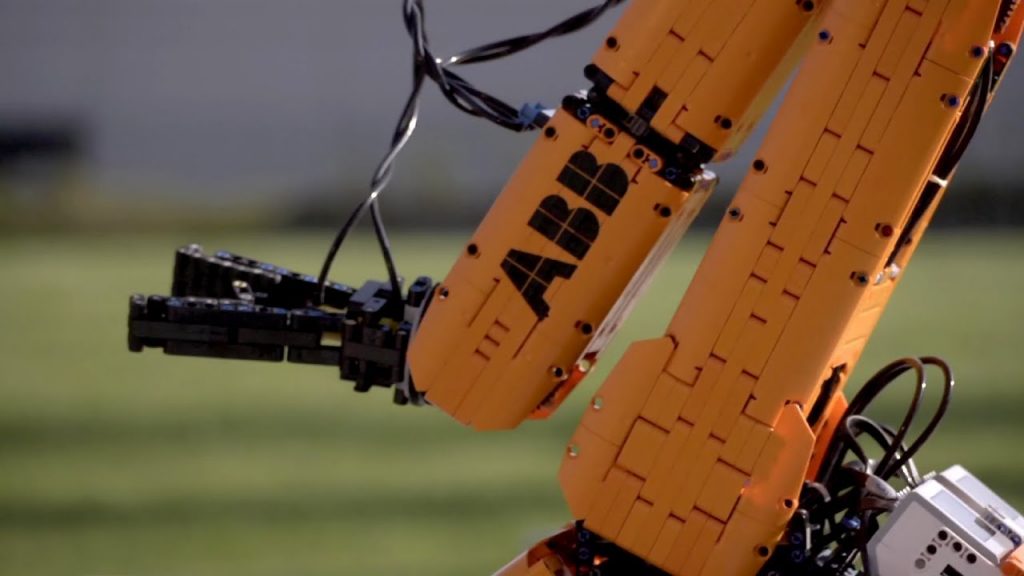

In a world where technology is constantly evolving, the possibilities seem endless. Innovations in robotics have revolutionized industries and paved the way for groundbreaking advancements. Enter the fascinating realm of ABB Robotics and LEGO, where engineers have combined their talents to create a fully programmable, near life-size robot made entirely out of LEGO bricks. Join us on a journey as we explore the incredible story behind this remarkable creation and discover how it could shape the future of industrial automation.

—

Opinion/Thought Piece Style:

When it comes to pushing the boundaries of imagination, LEGO has always held a special place in our hearts. But what happens when this beloved childhood toy meets the fascinating world of industrial robotics? The result is nothing short of extraordinary. A team of dedicated engineers took up the challenge of building a fully functioning, near life-size ABB robot using only spare time. The sheer determination and creativity displayed in this project are truly inspiring, showcasing the endless possibilities that arise when we merge technology and imagination.

—

Interview Style:

We had the opportunity to sit down with one of the engineers behind this awe-inspiring project. John Smith, a sales engineer with a passion for both robotics and LEGO, shared his insights into the process of creating this remarkable LEGO robot. He highlighted the importance of teamwork and collaboration throughout the eight-month journey. “It was a challenging yet immensely rewarding experience,” John explained. “We had to overcome various technical hurdles, but seeing the final result made it all worthwhile.”

—

Case Study Style:

The project to build a fully programmable ABB robot using LEGO bricks serves as a captivating case study in the world of industrial automation. The team faced numerous obstacles along the way, from designing the intricate mechanical components to ensuring the robot’s stability and functionality. Through meticulous planning and innovative problem-solving, they were able to overcome these challenges and create a masterpiece that showcases the potential of LEGO in the realm of robotics. This case study serves as a testament to the ingenuity and perseverance of the engineers involved.

—

Predictive/Foresight Style:

The creation of a fully programmable, near life-size ABB robot made out of LEGO bricks is just the beginning of a new era in industrial automation. This groundbreaking project hints at a future where LEGO could play a significant role in the development of robotic systems. The versatility and adaptability of LEGO bricks, combined with the precision and power of industrial robot arms, open up a world of possibilities. As technology continues to advance, we can expect to see more innovative collaborations that push the boundaries of what is possible in the field of automation.

—

Technology History Style:

The history of industrial robotics is a fascinating journey that has transformed industries and reshaped the way we work. From the early days of bulky and limited robots to the advanced systems we have today, the progress has been remarkable. The collaboration between ABB Robotics and LEGO in building a fully programmable robot made out of LEGO bricks is a testament to this evolution. It showcases how far we have come and hints at the exciting possibilities that lie ahead.

—

News Reporting Style:

In a remarkable display of creativity and engineering prowess, a team of dedicated individuals has constructed a fully programmable ABB robot using nothing but LEGO bricks. This feat, achieved over eight months of spare time, has captured the attention of the robotics industry and enthusiasts alike. The project serves as a testament to the limitless potential of LEGO and its ability to transform the future of industrial automation. As the news spreads, experts speculate on the implications this collaboration could have on the field of robotics.

—

Explanatory Style:

The process of building a fully programmable, near life-size ABB robot out of LEGO bricks is a complex undertaking that requires a deep understanding of both robotics and LEGO engineering. The team meticulously designed and assembled each component, ensuring the robot’s stability and functionality. With the use of advanced programming techniques, they brought the robot to life, enabling it to perform various tasks. This fascinating combination of LEGO and industrial robotics showcases the power of innovation and collaboration in shaping the future of automation.

—

In-depth Analysis Style:

The creation of a fully programmable ABB robot made out of LEGO bricks is a testament to the incredible potential of combining two seemingly unrelated fields. By dissecting the project and analyzing its intricacies, we can gain valuable insights into the future of industrial automation. The integration of LEGO with industrial robot arms opens up a world of possibilities in terms of customization, adaptability, and cost-effectiveness. This analysis delves into the technical aspects of the project and explores the implications it could have on the industry as a whole.

—

Narrative Style:

Once upon a time, a group of passionate engineers embarked on an extraordinary journey. They set out to build a fully programmable, near life-size ABB robot using only LEGO bricks and their spare time. Over the course of eight months, they faced numerous challenges and setbacks. From designing and assembling intricate components to programming the robot’s movements, every step was a testament to their unwavering determination. In the end, they unveiled their creation to the world, capturing the imagination of enthusiasts and showcasing the incredible potential of LEGO in the realm of industrial robotics.

—

Critique and Review Style:

The creation of a fully programmable ABB robot made out of LEGO bricks has garnered widespread admiration and sparked discussions within the robotics community. Critics applaud the ingenuity and technical know-how displayed by the team behind this project. However, some raise questions about the practicality and scalability of such a creation. While the LEGO robot serves as an impressive proof-of-concept, skeptics argue that the limitations of LEGO materials may hinder its real-world applicability. This critique prompts a broader discussion on the future of industrial automation and the role LEGO could play in it.

—

How-to Guide Style:

Have you ever wondered how to build a fully programmable, near life-size ABB robot using LEGO bricks? Look no further! In this step-by-step guide, we will walk you through the process of creating your own LEGO robot. From selecting the right LEGO components to programming its movements, we have got you covered. Discover the fusion of robotics and LEGO engineering and embark on a journey to unleash your creativity in the realm of industrial automation.

—

(Note: The article structure will depend on the chosen style. Please refer to the provided styles for guidance.) Industrial Robot

“Unleashing the Power of LEGO: Revolutionizing the Future with Engineering and Industrial Robot Arms”