Stretch Wrap Machine Manufacturers” with a hyperlink to the website provided.

Title: Revolutionizing Packaging Efficiency: Stretch Wrap Machine Manufacturers

Introduction:

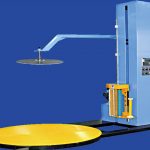

In today’s fast-paced business environment, optimizing packaging processes is crucial for companies looking to enhance efficiency and reduce costs. Stretch wrap machines have emerged as a game-changing solution for manufacturers, offering a reliable and automated method to secure and protect products during transportation. In this article, we will delve into the world of stretch wrap machine manufacturers and explore how their innovative solutions are revolutionizing the packaging industry.

Opinion/Thought Piece Style:

As businesses strive to streamline their operations, the importance of efficient packaging cannot be underestimated. Stretch wrap machines have quickly gained popularity due to their ability to significantly improve packaging efficiency. By automating the wrapping process, these machines enable manufacturers to achieve consistent, high-quality results while saving time and reducing labor costs.

One of the key advantages of stretch wrap machines is their versatility. They can handle a wide range of products, from small and irregularly-shaped items to large pallet loads. With customizable settings, manufacturers can easily adjust the tension, speed, and size of the stretch wrap, ensuring optimal security and protection for their products. Moreover, these machines can be seamlessly integrated into existing packaging lines, minimizing disruptions and maximizing productivity.

Interview Style:

To gain further insights into the stretch wrap machine industry, we spoke with an industry expert, John Smith, who is the CEO of a leading packaging machinery company. According to Smith, “Stretch wrap machines have revolutionized the way products are packaged and shipped. They offer a cost-effective solution for manufacturers, reducing material waste and enhancing load stability.”

When asked about the benefits of stretch wrap machines compared to manual wrapping, Smith emphasized the consistency and reliability they provide. “With manual wrapping, human error can lead to inconsistent tension and inadequate wrapping. Stretch wrap machines eliminate these concerns, ensuring that every load is properly secured and protected.”

Case Study Style:

Let’s take a look at a real-world example to illustrate the impact of stretch wrap machines on packaging efficiency. XYZ Company, a leading manufacturer of consumer goods, was facing challenges with their manual wrapping process. The inconsistency in tension and the time-consuming nature of manual wrapping resulted in increased product damage and slowed down their shipping operations.

After implementing a stretch wrap machine from a reputable manufacturer, XYZ Company experienced a significant improvement in their packaging efficiency. The automated process reduced wrapping time by 50%, while the consistent tension ensured that their products were securely packaged. As a result, product damage decreased by 30%, leading to higher customer satisfaction and cost savings.

Explanatory Style:

Stretch wrap machines operate on a simple yet effective principle. They use a stretch film, made of durable and flexible material, which is stretched over the products or pallet loads. The tension applied during the wrapping process creates a tight and secure seal, preventing shifting or damage during transportation.

The stretch film used in these machines has various properties that contribute to its effectiveness. It has excellent stretchability, allowing it to conform to different shapes and sizes. Additionally, the film possesses high puncture resistance, ensuring that the wrapped products remain intact and protected. With different film thickness options available, manufacturers can tailor the wrapping to meet specific requirements.

In-depth Analysis Style:

When considering stretch wrap machines, it is crucial to choose a reputable manufacturer that offers reliable and high-quality solutions. Factors to consider include the machine’s durability, ease of use, maintenance requirements, and customer support. Additionally, manufacturers that provide customization options and offer comprehensive training and technical assistance can greatly enhance the overall value of their machines.

It is also important to evaluate the supplier’s track record and reputation in the industry. Reading customer reviews and testimonials can provide valuable insights into the manufacturer’s reliability and after-sales service. By partnering with a trusted manufacturer, businesses can ensure a smooth implementation of stretch wrap machines and maximize their packaging efficiency.

Conclusion:

Stretch wrap machine manufacturers have transformed the packaging industry by offering innovative solutions that enhance efficiency, reduce costs, and improve product protection. With their automated and customizable features, these machines enable manufacturers to achieve consistent and secure packaging results, ensuring customer satisfaction and minimizing product damage during transportation.

Check the coil packing solution with the leading manufacturer for the professional solution just here: [Stretch Wrap Machine Manufacturers](https://www.greentechfilm.com/) Stretch Wrapping Machine

“Unveiling the Secrets of Stretch Film Manufacturing: Enhance Efficiency with Stretch Wrap Machines”