Check out our video on mold manufacturing and injection molding! As a sales engineer in the industry, I’m excited to share with you some insights and information about the process. In this article, we’ll dive into the world of plastic injection machine manufacturers, discuss the importance of mold processing and manufacturing, and explore the various applications of injection molding.

Plastic injection machine manufacturers play a crucial role in the manufacturing industry. These companies specialize in producing high-quality machines that are capable of efficiently and effectively molding plastic materials into a variety of shapes and forms. With their expertise, they provide the necessary tools and technology to enable the production of plastic injection molding products.

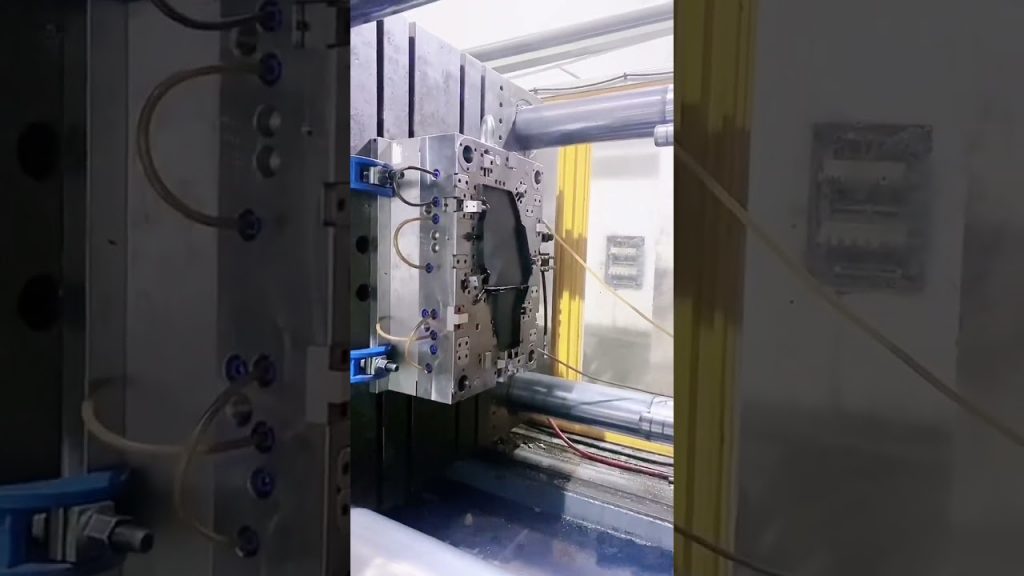

Mold processing and manufacturing is an essential step in the production of plastic injection molding products. It involves the creation of molds that will be used to shape the plastic materials. This process requires precision and expertise to ensure that the molds are accurately designed and constructed. The molds are then used in the injection molding machines to produce the final products.

Injection molding is a versatile manufacturing process that allows for the production of a wide range of plastic products. It involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. This process is widely used in various industries, including automotive, electronics, medical, and consumer goods.

One of the key advantages of injection molding is its ability to produce complex and intricate parts with high precision and consistency. This makes it a preferred choice for manufacturers who require intricate designs and tight tolerances. Additionally, injection molding offers cost-effective production solutions, as it allows for mass production of parts with minimal material waste.

Overmolding injection molding is another technique that is commonly used in the industry. It involves molding one material, typically a softer material, over another material, creating a multi-material product. This technique is often used to enhance the functionality and aesthetics of the final product. Overmolding provides added durability, improved grip, and a more attractive appearance.

In this video, we will explore the various applications of plastic injection molding products. From automotive components to medical devices, plastic injection molding has revolutionized the way we manufacture products. We will also showcase the latest advancements in injection molding technology and how it is shaping the future of manufacturing.

Whether you are a manufacturer looking to optimize your production process or a consumer interested in learning more about the products you use, this video will provide valuable insights and information. Join us as we explore the world of mold manufacturing and injection molding.

Check out the video now to learn more about plastic injection machine manufacturers and the fascinating world of injection molding. Don’t miss out on the opportunity to gain valuable knowledge and stay up-to-date with the latest trends and advancements in the industry.

[Video link goes here]

Remember, for all your mold processing and manufacturing needs, trust the experts in the field. Plastic injection machine manufacturers are here to provide you with top-notch solutions and ensure the success of your projects. So, what are you waiting for? Watch the video now and discover the endless possibilities of plastic injection molding!

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert link here] Plastic Injection Machine

“Exploring the World of Injection Molding: Techniques, Products, and Manufacturers”