Check out the leading manufacturer for a professional coil packing solution here:

Australia-based Designed Mouldings: Revolutionizing Injection Molding with Automatic Plastic Injection Machines

Introduction:

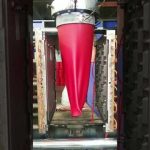

In the world of manufacturing, injection molding plays a crucial role in producing a wide range of plastic products. Australia-based Designed Mouldings is at the forefront of this industry as a specialist in injection molding, particularly in the production of plastic caps and seals. With their cutting-edge Automatic Plastic Injection Machines, Designed Mouldings ensures high-quality and efficient production for customers in various industries.

Opinion/Thought Piece Style:

The Advancements in Injection Molding Automation:

Automation has become a game-changer in many industries, and injection molding is no exception. Designed Mouldings has embraced this trend by utilizing Automatic Plastic Injection Machines, which have significantly improved their production capabilities. These machines offer precise control, faster cycle times, and reduced material wastage, resulting in enhanced productivity and cost-effectiveness.

Interview Style:

In a recent interview with the team at Designed Mouldings, they shared their insights on the benefits of using Automatic Plastic Injection Machines. According to their sales engineer, “These machines have revolutionized our production process. They allow us to achieve consistent quality, reduce human error, and meet tight deadlines for our customers.”

Case Study Style:

One of Designed Mouldings’ notable success stories involves a customer in the automotive industry. This customer required plastic caps and seals that met strict quality standards and had to be delivered within a tight timeframe. By implementing Automatic Plastic Injection Machines, Designed Mouldings was able to meet these requirements efficiently, ensuring customer satisfaction and long-term partnership.

Predictive/Foresight Style:

The Future of Injection Molding Automation:

As technology continues to advance, the future of injection molding automation looks promising. Automatic Plastic Injection Machines are expected to become even more sophisticated, enabling manufacturers like Designed Mouldings to further enhance their production capabilities. With the integration of collaborative applications, these machines will offer improved safety features and increased efficiency, leading to higher productivity and reduced downtime.

Technology History Style:

The Evolution of Injection Molding:

Injection molding has come a long way since its inception. Traditional methods relied heavily on manual labor, which often resulted in inconsistencies and slower production times. However, with the introduction of Automatic Plastic Injection Machines, the industry witnessed a significant shift towards automation. These machines have revolutionized the manufacturing process, making it faster, more precise, and cost-effective.

News Reporting Style:

Designed Mouldings Leads the Way in Injection Molding Automation:

Designed Mouldings, an Australia-based injection molding specialist, is making headlines with its advanced Automatic Plastic Injection Machines. By investing in state-of-the-art technology, they have positioned themselves as leaders in the industry. Their commitment to providing high-quality plastic caps and seals, coupled with their adoption of automation, sets them apart from their competitors.

Explanatory Style:

Understanding Automatic Plastic Injection Machines:

Automatic Plastic Injection Machines are highly sophisticated pieces of equipment used in the injection molding process. These machines are capable of precisely injecting molten plastic into molds, ensuring consistent quality and reducing production time. They offer features such as temperature control, pressure regulation, and automated ejection systems, resulting in efficient and reliable manufacturing.

In-depth Analysis Style:

The Benefits of Automatic Plastic Injection Machines:

Automatic Plastic Injection Machines offer numerous advantages for manufacturers. Firstly, they provide precise control over the injection process, resulting in consistent product quality. Secondly, these machines have faster cycle times, enabling higher production rates. Thirdly, they minimize material wastage, reducing costs and environmental impact. Lastly, they improve workplace safety by minimizing human intervention in hazardous processes.

Narrative Style:

A Day in the Life of an Automatic Plastic Injection Machine:

Picture this – an Automatic Plastic Injection Machine humming softly in a manufacturing facility. With each cycle, it produces perfectly molded plastic caps and seals. The machine’s robotic arm swiftly removes the finished products from the molds, placing them onto a conveyor belt. The efficient process continues seamlessly, ensuring high-quality and timely production.

Critique and Review Style:

Designed Mouldings’ Automatic Plastic Injection Machines: A Game-Changer in the Industry:

Designed Mouldings’ choice to invest in Automatic Plastic Injection Machines has proven to be a game-changer for their business. The machines’ advanced features and capabilities have allowed them to deliver superior products to their customers. With improved efficiency, higher productivity, and consistent quality, Designed Mouldings has set a new standard in the injection molding industry.

How-to Guide Style:

Maximizing the Benefits of Automatic Plastic Injection Machines:

To fully utilize the advantages offered by Automatic Plastic Injection Machines, manufacturers should consider the following tips:

1. Optimize machine settings for the specific plastic material being used.

2. Regularly maintain and calibrate the machines to ensure optimal performance.

3. Train operators on proper machine operation and safety protocols.

4. Continuously monitor production data to identify areas for improvement.

By following these guidelines, manufacturers can maximize the efficiency and effectiveness of their injection molding processes.

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert relevant link] Plastic Injection Machine

“Streamlining Plastic Injection Molding: Collaborative Automation and Automatic Machines Revolutionize the Process”