Check out our leading manufacturer for the professional solution here:

Are you tired of using traditional hair combs and looking for something more innovative? Look no further! In this YouTube video, we will introduce you to the fascinating world of 2 Colour Comb plastic injection molding machines. With our advanced 2 Screw barrel Unit, you can create unique and colorful hair combs that will make a style statement.

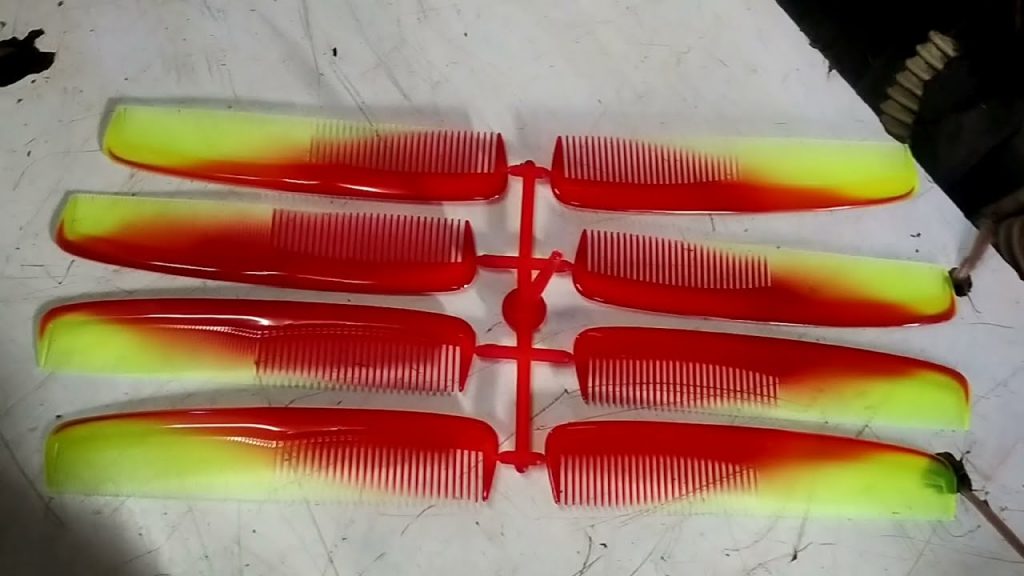

The process of manufacturing a 2 colour ki kangi, also known as a color wala comb, using a plastic injection molding machine is truly mesmerizing. By combining two different colors of plastic, you can create stunning designs and patterns that will enhance your hair styling routine. Whether you want a subtle ombre effect or a bold contrast, our machine can fulfill all your creative desires.

Plastic Injection Machine Manufacturers play a crucial role in bringing this technology to life. They are the experts behind the design and development of these machines, ensuring their efficiency and reliability. With their extensive knowledge and experience, they have revolutionized the hair comb industry, offering a wide range of options for hairstylists and individuals alike.

Now, let’s dive deeper into the technical aspects of the 2 Colour Comb plastic injection molding machine. The machine consists of a 2 Screw barrel Unit, which is responsible for injecting the molten plastic into the mold cavity. This unit ensures precise control over the color distribution, allowing you to create intricate designs with ease.

The process begins by melting the plastic pellets in the machine’s barrel. The two colors are carefully selected and loaded into separate hoppers. As the plastic melts, it is pushed forward by the rotating screw, mixing the two colors together. Once the desired color combination is achieved, the molten plastic is injected into the mold cavity, where it takes the shape of the hair comb.

The mold plays a crucial role in determining the final design of the comb. It is created with precision and accuracy, ensuring that every detail is captured perfectly. The molten plastic fills the mold cavity under high pressure, ensuring a smooth and flawless finish. Once the plastic cools down and solidifies, the mold is opened, and the finished comb is ejected.

The 2 Colour Comb plastic injection molding machine offers numerous advantages over traditional manufacturing methods. It allows for faster production, higher precision, and cost-effective manufacturing. With this technology, you can create customized combs in a variety of colors and designs, catering to the unique preferences of your customers.

In conclusion, the 2 Colour Comb plastic injection molding machine has revolutionized the hair comb industry. With its advanced 2 Screw barrel Unit and the expertise of Plastic Injection Machine Manufacturers, it offers endless possibilities for creating stunning and vibrant hair combs. Say goodbye to boring and traditional combs, and embrace the colorful world of injection molding technology.

Check out our leading manufacturer for the professional solution here: [link to the manufacturer’s website] Plastic Injection Machine

“Efficient Plastic Injection Molding for Two-Color Combs: A Comprehensive Look at Leading Manufacturers”