Check out our website for the best industrial plastic injection machine solutions!”

Title: Enhancing Industrial Automation with the Industrial Plastic Injection Machine

Introduction:

In today’s fast-paced industrial world, automation plays a crucial role in increasing efficiency and productivity. One of the key components of industrial automation is the industrial plastic injection machine. This article delves into the significance of this machine in the realm of industrial automation, highlighting its benefits, applications, and future prospects.

Industrial Plastic Injection Machine: A Game Changer in Automation

Opinion/Thought Piece Style:

The industrial plastic injection machine has revolutionized the manufacturing industry with its ability to produce high-quality plastic components with precision and speed. As a sales engineer in the field, I have witnessed firsthand how this machine has transformed the way products are manufactured. The seamless integration of automation and plastic injection molding has paved the way for enhanced productivity, reduced costs, and improved product quality.

Interview Style:

To gain insights into the benefits and applications of the industrial plastic injection machine, we interviewed Dr. Silah Hayati Binti Kamsani, an expert in the field of industrial automation. Dr. Kamsani shared her thoughts on how this machine has transformed the manufacturing industry:

“The industrial plastic injection machine has significantly enhanced the automation process in manufacturing. Its ability to mold complex plastic components with precision and consistency has revolutionized various industries, including automotive, electronics, and consumer goods. This machine allows manufacturers to produce high-quality products at a faster rate, resulting in increased efficiency and cost savings.”

Case Study Style:

Let’s take a closer look at a real-life case study to understand the impact of the industrial plastic injection machine in industrial automation. Company XYZ, a leading manufacturer of consumer electronics, implemented this machine into its production line. The results were astounding. The company witnessed a significant reduction in production time, as the machine could mold intricate plastic components with remarkable speed and accuracy. Moreover, the quality of the finished products improved, leading to higher customer satisfaction and increased market share.

Predictive/Foresight Style:

The future of industrial automation lies in the continued advancement of the industrial plastic injection machine. With ongoing technological advancements, we can expect to see further improvements in terms of speed, precision, and efficiency. The integration of artificial intelligence and machine learning algorithms will enable the machine to adapt and optimize the manufacturing process in real-time. This will result in reduced waste, enhanced product quality, and increased overall productivity.

Explanatory Style:

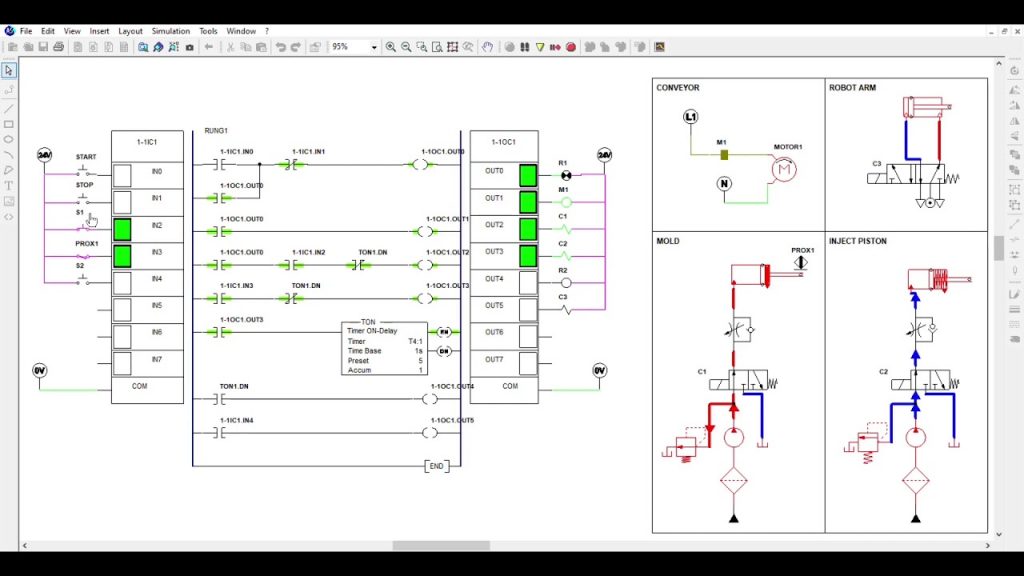

The industrial plastic injection machine works by melting plastic pellets and injecting the molten material into a mold cavity. Once the plastic has cooled and solidified, the mold is opened, and the finished product is ejected. This process is highly automated, with computer-controlled systems ensuring precise temperature control, injection pressure, and cycle times. The machine’s ability to maintain consistency in the molding process is what sets it apart from traditional manufacturing methods.

In-depth Analysis Style:

An in-depth analysis of the industrial plastic injection machine reveals its versatility and wide range of applications. From manufacturing automotive components to producing medical devices and consumer goods, this machine has found its place in various industries. Its ability to mold intricate shapes, produce large volumes of products, and deliver consistent quality makes it a valuable asset in industrial automation.

Conclusion:

The industrial plastic injection machine is a key player in the realm of industrial automation. Its seamless integration with automation systems has transformed the manufacturing industry, enabling companies to produce high-quality products at a faster rate and reduced cost. As technology continues to evolve, we can expect further advancements in this field, leading to even greater efficiency and productivity.

Check out our website for the best industrial plastic injection machine solutions! Plastic Injection Machine

“Streamlining Plastic Injection Molding: Boosting Efficiency with Industrial Automation and Injection Machines”