Check out our leading manufacturer for professional coil packing solutions here: [insert URL]”

Title: Exploring the Efficiency and Benefits of Semi-Automatic Plastic Injection Machines

Introduction:

In today’s fast-paced manufacturing industry, efficiency and precision are key factors for success. When it comes to plastic injection molding, the right machinery plays a critical role in achieving optimum results. In this article, we will delve into the world of semi-automatic plastic injection machines, discussing their features, benefits, and how they can revolutionize the plastic injection molding process.

Section 1: Understanding Semi-Automatic Plastic Injection Machines

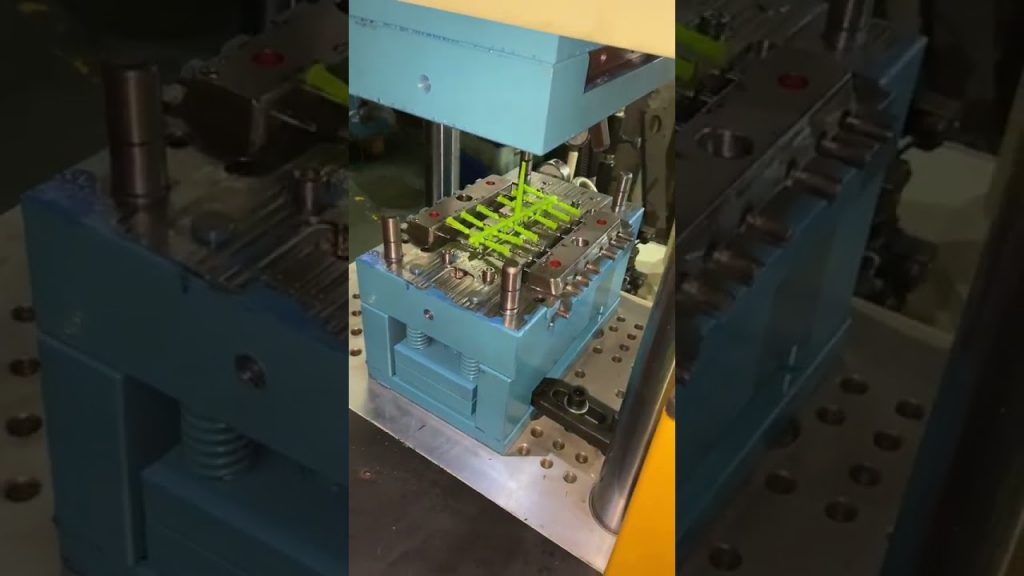

– Definition and Overview: A brief explanation of what semi-automatic plastic injection machines are and how they differ from fully automatic machines.

– Key Components: Explore the various components that make up a semi-automatic plastic injection machine, highlighting their importance in the overall functionality.

– Operation Process: Step-by-step breakdown of how these machines operate, from raw material preparation to the final product.

Section 2: Advantages of Semi-Automatic Plastic Injection Machines

– Cost-Effectiveness: Discuss the cost benefits of semi-automatic machines compared to fully automatic ones, emphasizing the reduced initial investment and operational expenses.

– Flexibility: Highlight how semi-automatic machines offer greater flexibility, allowing manufacturers to easily switch between different molds and products.

– Increased Control: Explain how these machines provide manufacturers with more control over the injection process, ensuring consistent quality and precision.

Section 3: Applications and Industries Benefiting from Semi-Automatic Plastic Injection Machines

– Automotive Industry: Discuss the role of semi-automatic plastic injection machines in the automotive industry, where precision and durability are of utmost importance.

– Consumer Electronics: Explore how these machines cater to the production needs of consumer electronics, ensuring efficient and reliable manufacturing processes.

– Medical Devices: Highlight the significance of semi-automatic machines in the production of medical devices, where precision and hygiene are crucial.

Section 4: Case Studies: Real-Life Examples of Success with Semi-Automatic Plastic Injection Machines

– Company A: Share a success story of a company that implemented semi-automatic plastic injection machines and experienced significant improvements in efficiency and product quality.

– Company B: Discuss another case study where a company successfully transitioned from fully automatic to semi-automatic machines, resulting in cost savings and enhanced production capabilities.

Conclusion:

Semi-automatic plastic injection machines offer a wide range of benefits for manufacturers in various industries. Their cost-effectiveness, flexibility, and increased control make them a valuable asset in achieving efficient and precise plastic injection molding. As technology continues to advance, it is important for manufacturers to stay updated with the latest machinery options to stay competitive in the market.

Check out our leading manufacturer for professional coil packing solutions here: [insert URL] Plastic Injection Machine

“Efficient and Precise Plastic Injection Molding Machines: Enhancing Productivity with Vertical and Semi-Automatic Models”