Check out our leading manufacturer for professional coil packing solutions right here:

The Machine Can Now Run Automatically and Unattended: A Breakthrough in Automatic Plastic Injection

Introduction

In the ever-evolving world of manufacturing, automation has become a game-changer. The latest breakthrough in this field is the development of an automatic plastic injection machine that can now operate without human intervention. This revolutionary advancement brings a host of benefits and opens up new possibilities for manufacturers in various industries.

The Unattended Operation of the Automatic Plastic Injection Machine

Gone are the days when a plastic injection machine required constant monitoring and manual control. With the latest advancements in technology, the machine can now run automatically and unattended. This means that manufacturers can set up the machine, start the production process, and leave it to operate on its own. This not only saves time and labor costs but also reduces the chances of human error and improves overall efficiency.

The Automatic Stop Function: Ensuring Quality and Safety

While unattended operation brings convenience, it is crucial to ensure that the machine can detect and address any problems that may arise. The automatic plastic injection machine is equipped with an advanced sensor system that can identify issues and immediately stop the operation if necessary. This ensures that any potential defects or malfunctions are detected early on, preventing further damage and ensuring the quality and safety of the final products.

The Finishing Touches: Achieving Perfection

Although the automatic plastic injection machine is capable of running unattended, there are still some finishing touches that may require human intervention. These touches include removing any excess plastic, inspecting the final products for defects, and making any necessary adjustments. While these tasks may seem minor, they play a crucial role in achieving perfection and delivering high-quality products to customers.

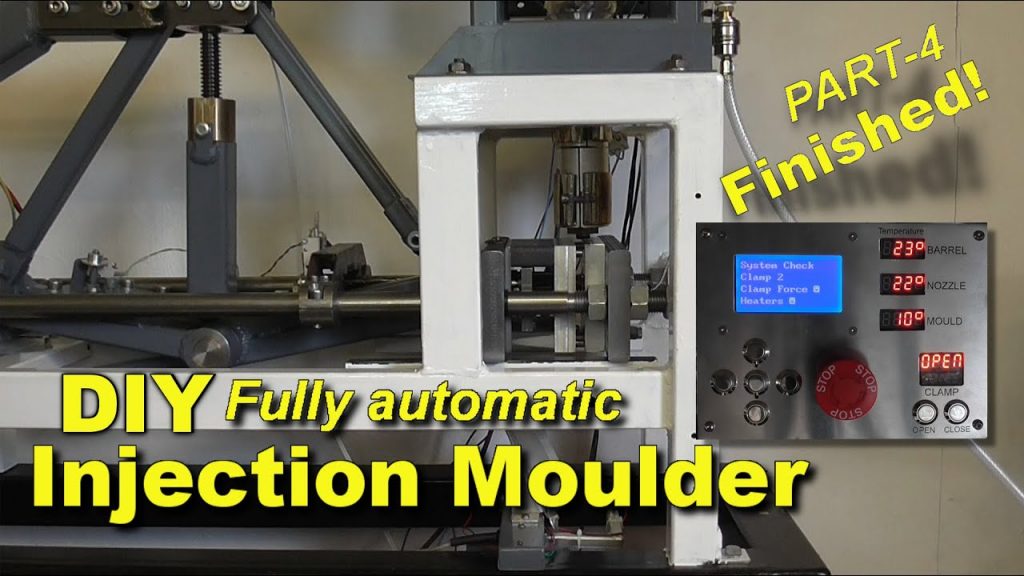

The DIY Automatic Injection Moulding Machine: An Exciting Opportunity

With the advancements in technology, it is now possible for individuals to build their own automatic injection moulding machine. DIY enthusiasts and small-scale manufacturers can now explore the world of plastic injection molding without the need for expensive machinery or extensive technical knowledge. This opens up an exciting opportunity for innovation and creativity, allowing individuals to bring their ideas to life.

Conclusion

The automatic plastic injection machine has brought a tremendous change to the manufacturing industry. With its ability to run unattended and its automatic stop function, it offers increased efficiency, improved quality, and enhanced safety. Moreover, the DIY automatic injection moulding machine empowers individuals to explore their creativity and innovation in the field of plastic molding. As technology continues to advance, we can expect even more exciting developments in the world of plastic injection molding.

Check out our leading manufacturer for professional coil packing solutions right here: [Manufacturer’s URL] Plastic Injection Machine

“Efficient DIY Injection Moulding Machine: Simple Steps to Build an Automatic Plastic Injection Device”