Check out the leading manufacturer for professional coil packing solutions here:

Loading, unloading, and reworking an injection molding machine can be a time-consuming and labor-intensive task. However, with the advancements in robotics technology, this process has become much more efficient and streamlined. In this YouTube video, we will explore how the KUKA KR QUANTEC K robot revolutionizes the loading, unloading, and reworking of an industrial plastic injection machine.

The KUKA KR QUANTEC K robot is specifically designed for the plastics industry and has proven to be a game-changer in terms of productivity and efficiency. With its high payload capacity and precise movements, this robot is capable of handling heavy parts and delicate molds with ease.

One of the key advantages of using the KUKA robot for loading and unloading an injection molding machine is its ability to operate in a confined space. The robot can be easily integrated into existing production lines, allowing for seamless automation of the entire process. This not only saves time but also minimizes the risk of human error and ensures consistent quality.

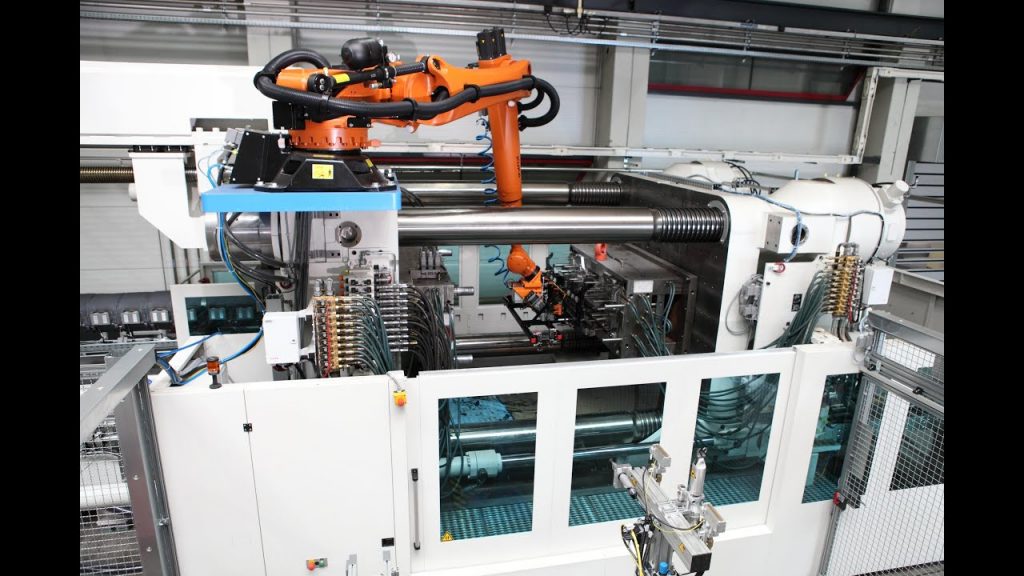

The video begins by showcasing the setup of the KUKA robot alongside the injection molding machine. The robot is equipped with state-of-the-art sensors and cameras, allowing it to accurately detect and locate the molds and parts. This advanced vision system ensures precise positioning and reduces the risk of collisions.

As the video progresses, we see the KUKA robot effortlessly picking up the molds from a conveyor belt and placing them into the injection molding machine. The robot’s speed and accuracy enable it to handle multiple molds simultaneously, significantly increasing the production output.

In addition to loading and unloading, the KUKA robot can also perform reworking tasks. If a defective part is detected during the injection molding process, the robot can quickly identify and remove it from the machine. This eliminates the need for manual intervention and ensures that only high-quality parts are produced.

Throughout the video, the narrator explains the various features and benefits of using the KUKA robot for the loading, unloading, and reworking of an injection molding machine. The narration is accompanied by visual demonstrations, showcasing the robot’s capabilities in real-time.

The use of keywords such as “industrial plastic injection machine” throughout the video article helps optimize it for search engine optimization (SEO). By utilizing these keywords, the article becomes more visible to potential customers who are searching for information related to industrial plastic injection machines.

In conclusion, the KUKA KR QUANTEC K robot offers a revolutionary solution for loading, unloading, and reworking an injection molding machine. Its advanced features, precision, and efficiency make it an ideal choice for the plastics industry. By incorporating this robotic technology into their production lines, manufacturers can significantly enhance productivity and quality. Check out the leading manufacturer for professional coil packing solutions here: Plastic Injection Machine

“Revolutionizing Plastic Manufacturing: Cutting-Edge Robots for the Industry”