Plastic Injection Machine Reviews: A Comprehensive Analysis of the Plastic Chair Manufacturing Process and Injection Molding Machines

Introduction:

Plastic injection machines play a vital role in the manufacturing industry, particularly in the production of plastic parts such as chairs. These machines use the injection molding process to create high-quality plastic products efficiently and with great precision. In this article, we will delve into the world of plastic injection machine reviews, exploring the manufacturing process of plastic chairs and the various types of injection molding machines available in the market.

I. Plastic Chair Manufacturing Process:

The process of manufacturing plastic chairs involves several stages, starting from the design phase to the final production. Here is a brief overview of the plastic chair manufacturing process:

1. Design and Prototyping:

The initial step in creating a plastic chair is designing and prototyping. Engineers use computer-aided design (CAD) software to develop a detailed 3D model of the chair, ensuring its functionality and aesthetic appeal.

2. Mold Creation:

Once the design is finalized, a mold is created. The mold serves as a template for the injection molding process and determines the shape and size of the plastic chair. It is crucial to design a mold that is durable, precise, and capable of producing consistent results.

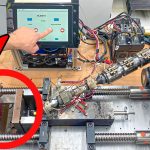

3. Injection Molding:

The injection molding process involves injecting molten plastic material into the mold cavity. The plastic material, usually in the form of pellets, is melted and then injected into the mold under high pressure. This ensures that the molten plastic fills the entire mold cavity, taking the shape of the chair.

4. Cooling and Ejection:

After the molten plastic is injected into the mold, it is left to cool and solidify. The cooling process is carefully monitored to ensure the plastic chair has the desired strength and structural integrity. Once cooled, the plastic chair is ejected from the mold, ready for further processing and finishing.

II. Plastic Injection Machine Reviews:

1. Types of Injection Molding Machines:

There are various types of injection molding machines available in the market. Here are a few commonly used types:

– Hydraulic Injection Molding Machines: These machines use hydraulic power to generate the necessary force for the injection molding process. They are known for their high production capacity and versatility.

– Electric Injection Molding Machines: Electric machines are becoming increasingly popular due to their energy efficiency, precision, and quiet operation. They offer faster cycle times and improved repeatability.

– Hybrid Injection Molding Machines: Hybrid machines combine the best features of hydraulic and electric machines. They offer high energy efficiency and excellent repeatability while maintaining high production capacity.

2. Factors to Consider When Choosing an Injection Molding Machine:

When selecting a plastic injection machine, it is essential to consider various factors. Some key considerations include:

– Production Capacity: Determine the required production capacity to ensure the machine can meet your demands.

– Precision and Quality: Look for machines that offer high precision and consistent quality to produce flawless plastic chairs.

– Energy Efficiency: Opt for machines that are energy efficient to reduce operational costs and minimize environmental impact.

– Maintenance and Support: Consider the availability of spare parts and after-sales support to ensure smooth operation and minimal downtime.

III. Conclusion:

Plastic injection machines are indispensable in the manufacturing of plastic chairs and other plastic parts. Understanding the plastic chair manufacturing process and the different types of injection molding machines allows manufacturers to make informed decisions when selecting the right machine for their production needs.

If you are looking for a reliable and professional solution for your plastic injection machine needs, check out leading manufacturers in the industry. They offer a wide range of high-quality machines that can cater to your specific requirements.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [insert relevant link]. Plastic Injection Machine

“Exploring the Fascinating Plastic Chair Manufacturing: Injection Molding Process & Machine Insights”