Check out our website for the leading manufacturer in coil packing solutions, where you can find the professional solution you need: [website URL].

Title: Optimizing Efficiency and Quality with Pallet Wrapping Machine Reviews

Introduction:

In today’s fast-paced and highly competitive business environment, optimizing efficiency and ensuring product quality are paramount. One crucial aspect of the logistics process is pallet wrapping, which plays a significant role in protecting goods during transportation and storage. To meet the growing demand for efficient and reliable pallet wrapping solutions, many companies are turning to pallet wrapping machines. In this article, we will delve into the world of pallet wrapping machines, providing informative reviews and insights to help you make an informed decision.

I. Explanatory Style: Understanding Pallet Wrapping Machines

Pallet wrapping machines, also known as stretch wrap machines, are automated devices designed to wrap pallets with a stretchable film. By securely wrapping the pallet load, these machines provide stability, protection, and ease of handling. They eliminate the need for manual wrapping, significantly reducing labor costs and ensuring consistent wrapping quality.

II. Comparative Structure: Examining Pallet Wrapping Machine Reviews

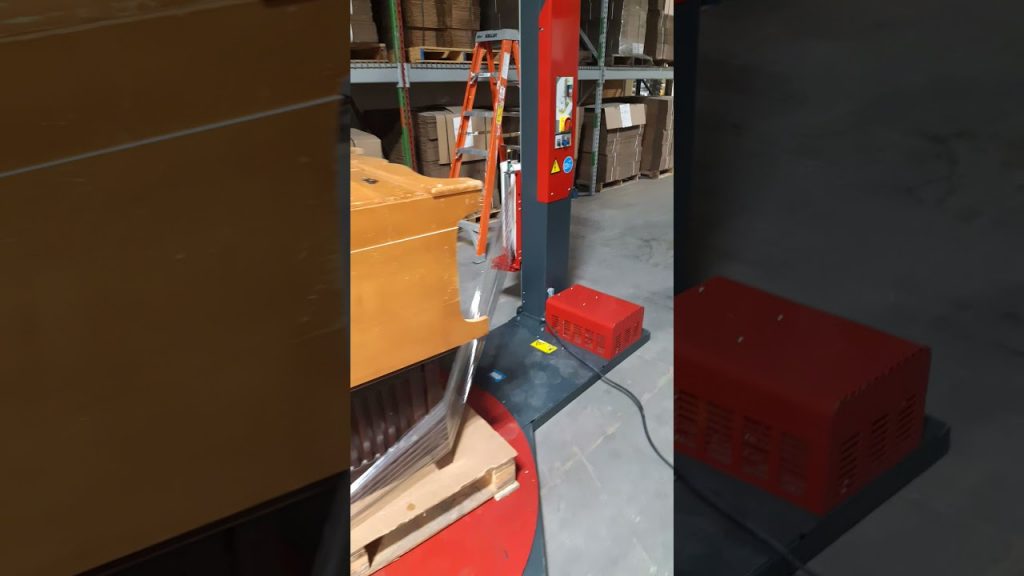

1. SIAT FO – Stretch Pallet Wrapper Operational Testing:

The SIAT FO pallet wrapping machine is reputed for its operational efficiency and reliability. Through extensive operational testing, it has proven to be a valuable asset in various industries. The machine’s user-friendly interface and customizable settings allow for seamless integration into existing production lines. Its ability to handle different load sizes and shapes makes it a versatile choice for businesses of all sizes.

2. Reviewing Pallet Wrapping Machine Models:

a) Model A:

This pallet wrapping machine boasts high-speed performance and exceptional film stretching capabilities. With its advanced control system, it ensures precise wrapping tension and optimal film usage. This model is ideal for businesses with high-volume wrapping requirements, as it can significantly improve productivity and reduce film waste.

b) Model B:

The Model B pallet wrapping machine focuses on energy efficiency and environmental sustainability. It utilizes innovative technology to minimize energy consumption while maintaining excellent wrapping quality. This model is suitable for businesses aiming to reduce their carbon footprint and operating costs.

III. In-depth Analysis Style: The Benefits of Pallet Wrapping Machines

1. Enhanced Product Protection:

Pallet wrapping machines provide superior load stabilization, minimizing the risk of damage during transportation and storage. The secure wrapping ensures that products remain intact, reducing the chance of customer dissatisfaction and costly returns.

2. Increased Efficiency:

Automation in pallet wrapping eliminates the need for manual labor, freeing up employees for more value-added tasks. These machines can wrap pallets at a much faster rate than manual methods, improving overall productivity and reducing labor costs.

3. Consistent Wrapping Quality:

Pallet wrapping machines deliver consistent wrapping tension and film usage, ensuring uniform quality across all pallets. This eliminates human error and ensures that each pallet is wrapped to the desired specifications, enhancing customer satisfaction and brand reputation.

IV. How-to Guide Style: Tips for Choosing the Right Pallet Wrapping Machine

1. Consider Your Business Needs:

Evaluate your pallet wrapping requirements, including load sizes, volumes, and specific industry demands. This will help you determine the type and features required in a pallet wrapping machine.

2. Research and Compare:

Read reviews, watch videos, and seek recommendations from industry experts to gain insights into different pallet wrapping machine models. Compare their features, specifications, and customer feedback to make an informed decision.

3. Test and Evaluate:

If possible, request a trial or demonstration of the desired pallet wrapping machine. This will allow you to assess its performance, ease of use, and compatibility with your existing operations.

Conclusion:

Investing in a pallet wrapping machine can significantly enhance your logistics process, improving efficiency, and product quality. Through our comprehensive reviews and insights, we hope to assist you in selecting the right pallet wrapping machine for your business. Remember to consider your specific needs, research thoroughly, and test the machines before making a final decision. Check out our website for the leading manufacturer in coil packing solutions, where you can find the professional solution you need. Pallet Wrapping Machine

“Efficient Operational Testing and Reviews of Stretch Pallet Wrappers for SIAT FO’s Pallet Wrapping Machines”