Title: “Revolutionizing Food Packaging: Automating the Process with MULTIVAC’s Advanced Packaging Line for Plant-Based Meat Products”

Description:

Introduction:

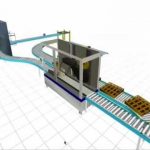

Welcome to our groundbreaking video showcasing the game-changing Automatic Food Packing Line, specifically designed for plant-based meat products. In collaboration with MULTIVAC, a renowned leader in packaging technology, and Zandbergen, a prominent importer of animal and plant-based protein products, this video provides an in-depth look at the cutting-edge packaging line that revolutionizes the food industry.

Video Content:

Our video delves into the exceptional capabilities of the Automatic Food Packing Line by MULTIVAC. This state-of-the-art packaging line is specifically tailored to meet the unique requirements of plant-based meat products, including those produced by the renowned brand, Beyond Meat. With precision engineering and innovative features, this packaging line ensures optimal efficiency, hygiene, and product integrity throughout the packaging process.

Key Highlights:

1. Unveiling MULTIVAC’s Automatic Food Packing Line: Discover the advanced machinery and technology that power this industry-leading packaging line.

2. Importance of Plant-Based Meat Packaging: Understand the significance of properly packaging plant-based meat products to maintain freshness, extend shelf life, and deliver an exceptional consumer experience.

3. Collaboration with Zandbergen: Learn about Zandbergen’s pivotal role as an importer of animal and plant-based protein products, and their commitment to delivering high-quality plant-based meat products to consumers worldwide.

4. Beyond Meat and the Plant-Based Revolution: Explore the rise of Beyond Meat as a key player in the plant-based meat industry and their partnership with MULTIVAC and Zandbergen.

Operation Steps:

1. Precise Product Handling: Discover how the Automatic Food Packing Line ensures gentle and accurate handling of plant-based meat products, minimizing damage and maintaining product quality.

2. Intelligent Weighing and Portioning: Witness the automated weighing and portioning process, guaranteeing consistency and accuracy in every package.

3. Advanced Packaging Materials: Learn about the innovative packaging materials utilized by MULTIVAC, ensuring optimal product preservation and safety.

4. Cutting-Edge Sealing and Labeling: Experience the seamless sealing and labeling process that enhances product presentation and ensures traceability.

Call to Action:

If you found this video informative and engaging, don’t forget to hit the like button, subscribe to our channel for more captivating content, and share this video with others who are interested in the future of food packaging. Your support is greatly appreciated.

Additional tags and keywords: automatic food packing line, automatic packaging line, MULTIVAC, plant-based meat products, Zandbergen, importer, animal-based protein products, plant-based protein products, Beyond Meat, packaging technology, revolutionizing food packaging

Hashtags: #AutomaticFoodPackingLine #PlantBasedMeatPackaging #RevolutionizingFoodPackaging #MULTIVAC #Zandbergen #BeyondMeat

Title: Automatic Packaging Line Tilter for Plant-Based Meat Products by MULTIVAC

Introduction:

In the rapidly growing market of plant-based meat products, efficient and automated packaging solutions are essential to meet the increasing demand. MULTIVAC, a leading provider of innovative packaging solutions, introduces an Automatic Packaging Line Tilter specifically designed for plant-based meat products. This cutting-edge solution ensures optimal packaging processes, enhancing productivity, and maintaining product integrity.

1. Enhanced Packaging Efficiency:

The Automatic Packaging Line Tilter by MULTIVAC streamlines the packaging process for plant-based meat products. By automating the tilting function, the tilter ensures seamless integration with existing packaging lines, reducing manual labor and increasing overall efficiency. This leads to faster throughput, allowing higher production volumes and meeting market demands.

2. Gentle Handling for Product Integrity:

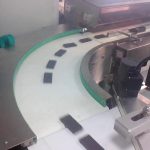

Product integrity is of utmost importance for plant-based meat products, as they can be more sensitive to handling compared to traditional meat products. MULTIVAC’s tilter is designed with special considerations to gently tilt and position the plant-based meat products without compromising their quality. This system reduces the risk of damage, maintaining the product’s appearance, texture, and taste.

3. Versatility and Customization:

MULTIVAC understands the diverse range of plant-based meat products available in the market. The Automatic Packaging Line Tilter can be easily customized to accommodate different product sizes, shapes, and weights. This versatility ensures compatibility with a wide range of plant-based meat products, providing manufacturers with the flexibility to adapt to changing consumer preferences.

4. Hygienic Design and Compliance:

Food safety and hygiene standards are critical in the food industry, and MULTIVAC prioritizes these aspects in their packaging solutions. The Automatic Packaging Line Tilter is designed with a focus on easy cleaning and maintenance, ensuring compliance with strict sanitation regulations. Stainless steel construction and seamless surfaces minimize the risk of bacterial growth, offering a hygienic packaging environment.

5. Integration with MULTIVAC’s Packaging Solutions:

The Automatic Packaging Line Tilter seamlessly integrates with MULTIVAC’s comprehensive packaging solutions, creating a fully automated packaging line for plant-based meat products. From product loading and weighing to sealing and labeling, MULTIVAC’s packaging systems work synergistically to maximize efficiency and optimize the packaging process.

Conclusion:

MULTIVAC’s Automatic Packaging Line Tilter for plant-based meat products revolutionizes the packaging industry by offering enhanced efficiency, gentle handling, versatility, and compliance with food safety regulations. This innovative solution enables manufacturers to meet the growing demand for plant-based meat products while maintaining product quality and integrity. By choosing MULTIVAC’s tilter, manufacturers can achieve higher productivity and ensure customer satisfaction in the competitive plant-based meat market. coil packing line

#Automatic #packaging #line #MULTIVAC #plant #based #meat #products