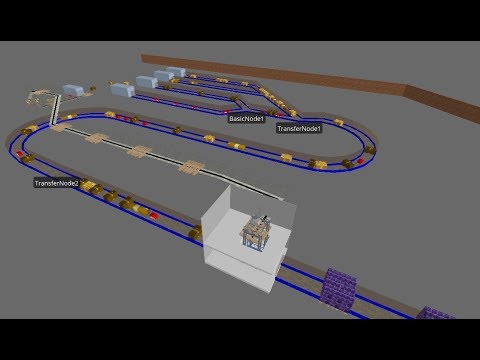

Check out our video on how our innovative packing system simulates the merging of four conveyor lines into one, resulting in all units being efficiently packaged onto a single pallet. In this article, we will explore the capabilities of our packing system and discuss its benefits for manufacturers.

Packing System Manufacturers play a crucial role in the manufacturing industry, providing solutions that streamline the packaging process and enhance productivity. Our goal is to offer a comprehensive packing system that meets the unique needs of manufacturers, ensuring efficiency, accuracy, and cost-effectiveness.

The Packaging System Simio Simulation manufacturing plant is a prime example of how our packing system can revolutionize the packaging process. Through advanced simulation technology, we are able to replicate real-life scenarios and optimize the efficiency of the packing system. By simulating the merging of four conveyor lines into one, we can demonstrate the benefits of our system in a controlled environment.

One of the key advantages of our packing system is its ability to maximize space utilization. By consolidating four conveyor lines into one, manufacturers can significantly reduce the footprint required for packaging. This not only saves valuable floor space but also allows for more streamlined operations and improved workflow.

Additionally, our packing system ensures accuracy and precision in packaging. With advanced sensors and control systems, each unit is carefully monitored and packaged according to the specified requirements. This eliminates errors and reduces the risk of damaged or incorrectly packaged products. Manufacturers can have peace of mind knowing that their products are being packaged with utmost care and precision.

Another significant benefit of our packing system is its scalability. As manufacturers grow and expand their operations, our system can easily accommodate increased production demands. With adjustable settings and customizable features, manufacturers can adapt the system to their evolving needs, ensuring seamless integration into their existing production lines.

Furthermore, our packing system is designed to enhance productivity and efficiency. By automating the packaging process, manufacturers can reduce manual labor and minimize the risk of human errors. This allows employees to focus on more value-added tasks, ultimately improving overall productivity and output.

In conclusion, our innovative packing system offers a range of benefits for manufacturers. From space utilization and accuracy to scalability and productivity, our system is designed to optimize the packaging process and drive efficiency. By simulating the merging of four conveyor lines into one, we showcase the capabilities of our system and its potential to revolutionize the packaging industry.

Check out the video to see our packing system in action and discover how it can transform your packaging operations. Trust the leading Packing System Manufacturers for a professional solution. Packing System

“Streamlining Manufacturing Processes: Simulating Packaging Systems for Efficient Manufacturing and Packaging Operations”