Industrial Robot Applications: Enhancing Efficiency and Productivity

Introduction:

In today’s fast-paced world, the integration of industrial robots has revolutionized various sectors, making them more efficient and productive. Industrial robots are programmable machines capable of performing repetitive tasks with precision, accuracy, and speed. With advancements in technology, these robots have become an integral part of many industries, transforming the way tasks are performed. In this article, we will delve into the diverse applications of industrial robots and explore how they have revolutionized industries across the globe.

Industrial Robot Applications:

1. Manufacturing Industry:

The manufacturing industry has witnessed a significant transformation with the introduction of industrial robots. These robots have streamlined production processes, resulting in increased efficiency and reduced costs. They can carry out tasks such as assembly, welding, painting, and material handling with unparalleled precision. By automating these repetitive and labor-intensive tasks, manufacturers can improve productivity and maintain consistent quality standards.

2. Automotive Industry:

The automotive industry has been at the forefront of adopting industrial robots. These robots are extensively used in various stages of automobile production, including welding, painting, and assembly. By utilizing robots for welding operations, manufacturers can ensure precise and uniform welds, leading to stronger and safer vehicles. Similarly, robots used for painting applications provide a flawless finish, eliminating any human errors. Furthermore, robots in the assembly process enhance speed and accuracy, resulting in faster production cycles.

3. Electronics Industry:

The electronics industry heavily relies on industrial robots for tasks such as circuit board assembly, soldering, and component testing. These robots can handle delicate components with utmost care, minimizing the risk of damage. The high precision and accuracy of these robots ensure consistent quality in the production of electronic devices. Additionally, robots can work at a faster pace, leading to increased productivity and reduced production time.

4. Food and Beverage Industry:

Industrial robots have found their way into the food and beverage industry, transforming various processes. From packaging to sorting, robots ensure hygienic and efficient operations. They can handle delicate food items without causing any damage and maintain strict hygiene standards. Robots equipped with vision systems can accurately identify and sort products based on size, shape, and color. This automation not only enhances productivity but also reduces the risk of contamination.

5. Pharmaceuticals Industry:

In the pharmaceutical industry, precision and accuracy are of utmost importance. Industrial robots play a crucial role in the production and packaging of pharmaceutical products. These robots can handle sensitive substances, ensuring precise measurements and minimizing errors. Moreover, robots can perform repetitive tasks with consistency, reducing the chances of contamination. By incorporating robots in pharmaceutical manufacturing, companies can improve efficiency, maintain quality standards, and meet stringent regulatory requirements.

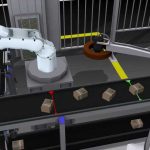

6. Logistics and Warehousing:

Industrial robots have revolutionized the logistics and warehousing industry by streamlining processes and improving operational efficiency. Autonomous mobile robots (AMRs) are used for material handling, inventory management, and order fulfillment. These robots can navigate through complex warehouse environments, pick and place items with precision, and optimize storage space. By automating these tasks, companies can reduce labor costs, minimize errors, and enhance overall productivity.

Conclusion:

The applications of industrial robots are vast and continue to expand across different industries. From manufacturing to logistics, these robots have transformed the way tasks are performed, enhancing efficiency and productivity. With advancements in technology, robots are becoming smarter, more versatile, and capable of handling complex operations. As industries embrace automation, the integration of industrial robots will undoubtedly play a pivotal role in shaping the future of manufacturing and other sectors.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

“Exploring the Versatile Applications of Industrial Robots with Mr. Yogesh Deshmukh”