Are you looking for a reliable and efficient solution for lacquering furniture and its components? Look no further than industrial robots! These advanced machines have revolutionized the manufacturing industry and can be successfully applied to the lacquering process. In this article, we will explore how the spraying robot RoboSpray, along with industrial robot training, can enhance your furniture production.

Industrial robots have become an integral part of various industries, including furniture manufacturing. Their precise movements, speed, and accuracy make them ideal for repetitive and intricate tasks like lacquering. With the right training and programming, these robots can consistently apply a smooth and even coat of lacquer to furniture, ensuring a high-quality finish.

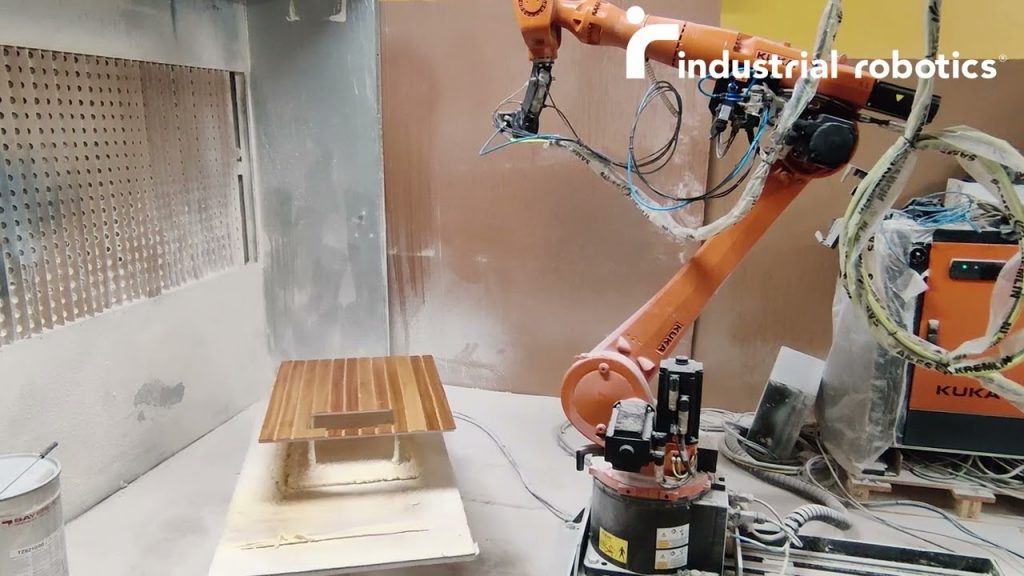

One of the leading industrial robots in the field of lacquering is RoboSpray. This spraying robot is designed specifically for the furniture industry and offers numerous advantages over traditional lacquering methods. RoboSpray eliminates the need for manual labor, reducing human error and increasing productivity. It can also work continuously for extended periods, ensuring consistent quality and faster production times.

To fully utilize the capabilities of RoboSpray and other industrial robots, it is crucial to provide proper training to your workforce. Industrial robot training equips your employees with the knowledge and skills to operate and program these advanced machines effectively. Training programs cover various aspects, including robot safety, programming languages, maintenance, and troubleshooting. With the right training, your employees will be able to maximize the potential of industrial robots and optimize your furniture production process.

The implementation of industrial robots in lacquering processes offers several benefits. Firstly, it improves the overall quality of the finished products. Industrial robots can consistently apply a precise and even layer of lacquer, eliminating inconsistencies and imperfections often associated with manual labor. This results in a superior finish and enhanced customer satisfaction.

Secondly, industrial robots significantly increase productivity. These machines work at a faster pace compared to manual labor, reducing production time and increasing output. With the ability to work continuously without breaks, industrial robots ensure a streamlined and efficient lacquering process.

Furthermore, industrial robots help reduce production costs in the long run. While the initial investment may seem high, the long-term benefits outweigh the costs. Industrial robots require minimal maintenance and have a longer lifespan compared to human workers. They also minimize material wastage by precisely applying the required amount of lacquer, leading to cost savings.

In conclusion, the integration of industrial robots, such as the spraying robot RoboSpray, in the lacquering process of furniture and its components offers numerous advantages. With their precise movements, speed, and accuracy, industrial robots ensure a high-quality finish and increase productivity. However, it is essential to provide proper industrial robot training to your workforce to fully utilize the potential of these advanced machines. By investing in industrial robots and training, you can enhance your furniture production, improve product quality, and reduce costs.

Check the lacquering solution with leading manufacturers for professional advice and solutions tailored to your specific needs. Don’t miss out on the opportunity to revolutionize your furniture production with industrial robots and industrial robot training. Industrial Robot

“Lacquering Excellence: Unleashing the Potential of Industrial Robots for RoboSpray and Training”