Check out the leading manufacturer for professional coil packing solutions here:”

Title: Revolutionizing Assembly Lines with Industrial Automation Robots

Introduction:

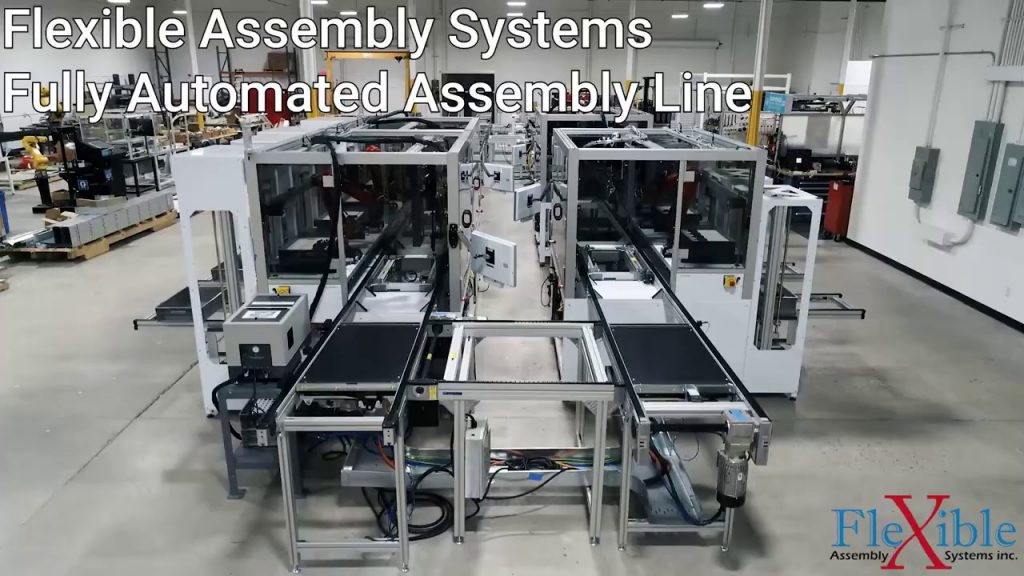

In today’s fast-paced manufacturing industry, efficiency and precision are key factors that determine the success of any assembly line. The advent of Industrial Automation Robots has revolutionized the way products are manufactured, enabling companies to achieve new levels of productivity and accuracy. One such example is the fully automated assembly line offered by Flexible Assembly Systems, which brings together cutting-edge technology and innovative engineering solutions. In this article, we will explore the capabilities and benefits of this large-scale assembly line, powered by Industrial Automation Robots.

Section 1: The Power of Industrial Automation Robots

Industrial Automation Robots have emerged as game-changers in the manufacturing sector. These advanced robots possess the ability to perform repetitive tasks with unparalleled precision, speed, and consistency. By integrating these robots into assembly lines, manufacturers can significantly enhance their productivity and reduce human error. The fully automated assembly line offered by Flexible Assembly Systems harnesses the power of Industrial Automation Robots to optimize the manufacturing process and deliver exceptional results.

Section 2: Unleashing Efficiency in Assembly Lines

The large-scale fully automated assembly line by Flexible Assembly Systems is designed to handle multiple tasks simultaneously, making it an ideal solution for industries with high-volume production requirements. Equipped with state-of-the-art Industrial Automation Robots, this assembly line can perform complex operations with utmost accuracy and efficiency. By removing the need for manual intervention in repetitive tasks, manufacturers can maximize their output while minimizing production time and costs.

Section 3: Precision and Quality Assurance

Industrial Automation Robots are renowned for their ability to consistently deliver accurate results. This fully automated assembly line ensures that each component is assembled with precision, eliminating the risk of human error. By adhering to strict quality control standards, manufacturers can guarantee the reliability and durability of their products. The integration of Industrial Automation Robots in the assembly line offered by Flexible Assembly Systems ensures that every product meets the highest standards of quality.

Section 4: Advantages of the Fully Automated Assembly Line

The fully automated assembly line by Flexible Assembly Systems offers numerous advantages for manufacturers seeking to streamline their operations. Firstly, it significantly reduces labor costs by minimizing the need for human workers in repetitive tasks. Secondly, it enhances productivity by increasing the speed and efficiency of the manufacturing process. Thirdly, it improves product quality by eliminating human errors and inconsistencies. Lastly, it enables manufacturers to meet the ever-growing demands of the market by delivering products at a faster rate.

Conclusion:

The integration of Industrial Automation Robots in the fully automated assembly line by Flexible Assembly Systems has transformed the manufacturing landscape, allowing companies to achieve unprecedented levels of efficiency and accuracy. By harnessing the power of these advanced robots, manufacturers can optimize their production processes, reduce costs, and deliver high-quality products. If you are looking for professional coil packing solutions, be sure to check out the leading manufacturer in the industry. With their cutting-edge technology and expertise, they can provide the perfect solution for your packaging needs. Industrial Robot

“Revolutionizing Manufacturing: The Future of Assembly Lines and Industrial Automation Robots Unleashed”