Title: Efficient and Automated Food Packing Line for China Panpan Foods | Cookies Bakery Full Automatic Sorting and Feeding

Description:

Introduction:

Welcome to our video showcasing the remarkable Automatic Food Packing Line for China Panpan Foods. In this video, we will provide an in-depth overview of this cutting-edge technology, highlighting its features, benefits, and operation steps. Stay tuned to discover how this fully automated sorting and feeding packing line revolutionizes the cookies bakery industry.

Video Content:

The Automatic Food Packing Line by China Panpan Foods is a game-changer in the bakery industry. This advanced system offers unparalleled efficiency, accuracy, and speed in packaging cookies with minimal human intervention. By implementing this innovative technology, Panpan Foods has taken their production process to the next level.

Key Features:

1. Full Automation: The packing line is designed to handle the complete packaging process from sorting to feeding, reducing the need for manual labor and increasing productivity.

2. Precision Sorting: With state-of-the-art sensors and advanced algorithms, the system ensures precise sorting of cookies based on various parameters such as size, weight, and shape.

3. Fast Feeding: The automated feeding mechanism seamlessly transfers cookies onto the packaging line, maintaining a steady flow and minimizing downtime.

4. Versatility: This packing line is adaptable to different types and sizes of cookies, offering flexibility in production.

Benefits:

1. Enhanced Efficiency: By eliminating manual sorting and feeding, the packing line significantly reduces production time, allowing for higher output and faster order fulfillment.

2. Improved Accuracy: The advanced sorting technology ensures that each package contains cookies of consistent quality, size, and weight, enhancing customer satisfaction.

3. Cost Savings: With reduced labor requirements and increased production capacity, businesses can achieve cost savings and maximize profitability.

4. Hygienic Packaging: The automated process minimizes human contact, ensuring a hygienic packaging environment and complying with food safety standards.

Operation Steps:

1. Cookie Sorting: The cookies are carefully sorted based on their characteristics, ensuring uniformity in each batch.

2. Feeding Process: The system automatically transfers the sorted cookies onto the packaging line, maintaining a continuous flow.

3. Packaging: The cookies are accurately packaged in airtight containers or bags, preserving their freshness and quality.

4. Quality Control: The packing line includes quality control checks to ensure that each package meets the highest standards before finalization.

Call to Action:

If you found this video informative and valuable, don’t forget to like, subscribe, and share it with others who might benefit from this innovative packing solution. Stay tuned for more exciting content on our channel.

Additional Tags and Keywords: automatic food packing line, cookies bakery, China Panpan Foods, sorting and feeding, full automatic, packaging technology, efficient packing line, automated bakery system.

Hashtags: #AutomaticFoodPacking #CookiesBakery #ChinaPanpanFoods #FullAutomaticSorting #FeedingPackingLine #InnovativeTechnology #EfficiencyInPackaging #AutomatedBakerySystem

Title: Fully Automated Sorting and Feeding Packing Line for China Panpan Foods

Introduction:

China Panpan Foods is a renowned bakery food manufacturer, known for its high-quality products, especially cookies. To enhance their production efficiency and ensure consistent quality, a fully automated sorting and feeding packing line is proposed for their bakery food manufacturing process. This state-of-the-art solution will streamline the sorting, feeding, and packing operations, ultimately boosting productivity and meeting the increasing market demands.

Objective:

The objective of this project is to design and implement a fully automatic sorting and feeding packing line specifically tailored to China Panpan Foods’ requirements. The system will enable efficient handling of bakery food products, particularly cookies, by sorting them based on specific criteria, feeding them seamlessly into the packing line, and ensuring accurate packaging for distribution.

Key Features:

1. Automated Sorting:

The sorting process will be performed using advanced optical sensors and computer vision technology. The system will categorize cookies based on predetermined parameters such as size, shape, color, and weight. This automated sorting process will eliminate human error, ensure consistency, and reduce the time required for manual sorting.

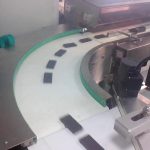

2. Seamless Feeding:

A conveyor belt system will be incorporated to transport the sorted cookies from the sorting station to the feeding area. This system will ensure a continuous flow of cookies, preventing any interruptions in the production line. The speed and direction of the conveyor belt can be adjusted to match the production requirements.

3. Robotic Feeding:

Robotic arms equipped with suction cups will be employed to precisely pick up the sorted cookies from the conveyor belt and place them onto the packaging trays. These robotic arms will be programmed to handle different cookie sizes and shapes, providing utmost accuracy and efficiency.

4. Packaging Flexibility:

The packing line will be designed to accommodate various packaging options, such as boxes, bags, or trays, depending on China Panpan Foods’ specific requirements. The system will be capable of handling different packaging sizes, allowing for greater flexibility in meeting customer demands.

5. Quality Control:

To ensure the highest quality standards, the automated sorting and feeding packing line will include quality control mechanisms. These mechanisms will detect any irregularities, such as broken or misshapen cookies, and divert them from the packing process, preventing defective products from reaching the market.

6. Data Monitoring and Analysis:

The system will be equipped with sensors and software to monitor and collect data throughout the production process. This data will be analyzed to identify potential bottlenecks, optimize efficiency, and track production trends for future planning.

Conclusion:

The fully automated sorting and feeding packing line proposed for China Panpan Foods will revolutionize their bakery food production process, specifically for cookies. By integrating advanced technology and robotics, this system will enhance efficiency, reduce human error, ensure consistent quality, and meet the growing market demands. This investment will position China Panpan Foods as a leader in the bakery food industry, providing high-quality cookies to its customers. coil packing line

#Cookies #bakery #food #full #automatic #sorting #feeding #packing #line #China #Panpan #foods