Title: Automated Bagging and Secondary Packaging System for Tea, Spices, Sugar, Flour, and Salt

Description:

Introduction:

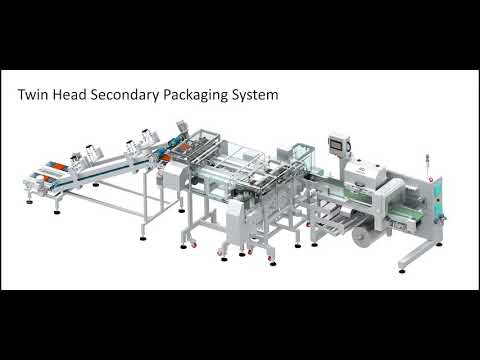

Welcome to our video showcasing the Automatic Bagging Packing Line, a highly efficient and advanced secondary packaging system designed for the Pouch in Bag System. This innovative solution is specifically developed for packaging tea, spices, sugar, flour, and salt, providing convenience and accuracy in bagging processes.

Video Content:

In this video, we delve into the features and operation steps of the Automatic Bagging Packing Line, highlighting its capabilities and benefits for various industries. Our aim is to provide you with an informative overview, enabling you to make an informed decision about incorporating this system into your packaging workflow.

Key Highlights:

– Efficient Bagging Process: Discover how the Automatic Bagging Packing Line streamlines the bagging process, increasing productivity and reducing manual labor requirements.

– Precision and Accuracy: Learn about the system’s precise weighing and filling mechanisms, ensuring consistent and accurate packaging of tea, spices, sugar, flour, and salt.

– Versatile Packaging Options: Explore the flexibility of the Pouch in Bag System, allowing for different bag sizes, materials, and sealing methods to meet your specific packaging needs.

– Advanced Technology: Gain insights into the cutting-edge features and automation capabilities of this packaging system, enhancing efficiency and reducing downtime.

– Quality Control and Traceability: Understand how the system incorporates quality control measures and traceability features, ensuring product integrity and regulatory compliance.

Call to Action:

If you’re looking to optimize your packaging process for tea, spices, sugar, flour, or salt, the Automatic Bagging Packing Line is the ideal solution. Contact us today at [Company Name] for more information and to discuss how this system can revolutionize your packaging operations.

Additional Tags and Keywords:

automated packaging system, secondary packaging solution, bagging machine, pouch packaging, tea packaging, spices packaging, sugar packaging, flour packaging, salt packaging

Hashtags:

#automatedpackagingsystem #secondarypackagingsolution #baggingmachine #pouchpackaging #teapackaging #spicespackaging #sugarpackaging #flourpackaging #saltpackaging

A tilter for a secondary packaging system for a Pouch in Bag system for Tea, Spices, Sugar, Flour, Salt can be designed as follows:

1. Design: The tilter will have a sturdy frame made of stainless steel to ensure durability and hygiene. It will consist of a tilting mechanism equipped with a motor and a control panel for easy operation.

2. Loading: The tilter will have a loading platform where the bags of tea, spices, sugar, flour, or salt will be placed. The platform will have adjustable side guides to accommodate different bag sizes and ensure stability during the tilting process.

3. Tilting mechanism: The motorized tilting mechanism will gently tilt the loaded bags from a horizontal position to an inclined angle. This will allow the bags to slide down smoothly and be transferred to the secondary packaging system.

4. Speed and angle adjustment: The tilter will have adjustable speed and tilting angle settings to accommodate various product requirements. This will ensure gentle handling of delicate items like tea leaves and prevent any damage.

5. Safety features: The tilter will be equipped with safety sensors to detect any obstruction or irregularities during the tilting process. In case of any abnormality, the tilter will automatically stop and alert the operator.

6. Control panel: The control panel will be user-friendly and intuitive, allowing the operator to easily adjust the settings, monitor the tilting process, and receive any error notifications.

7. Integration: The tilter will be designed to seamlessly integrate with the secondary packaging system, ensuring a smooth transition of the bags for further processing, such as sealing, labeling, or cartoning.

8. Maintenance and cleaning: The tilter will be designed for easy maintenance and cleaning, with removable parts and access points for quick inspections and adjustments.

Overall, this tilter for a secondary packaging system will provide a reliable and efficient solution for handling pouches of tea, spices, sugar, flour, salt, ensuring smooth transfer to the next stage of the packaging process. coil packing line

#Secondary #packaging #system #forPouch #Bag #System #Tea #Spices #Sugar #Flour #Salt