Title: Heavy Load Turning Made Easy with Coil Upender, Inverter & Upender for Pallet

Description:

Introducing our top-of-the-line load inverter and upender for turning heavy loads up to 180 degrees. With its advanced technology, it can safely and efficiently handle pallets and heavy load packages, making it the perfect solution for various industries such as manufacturing, logistics, and construction.

Our coil upender, inverter & upender for pallet and heavy load package is designed to provide an easy and hassle-free way of turning loads, reducing the risk of injuries and damages. It is equipped with a robust mechanism that ensures stability and balance during the entire turning process.

The video showcases the operation steps of the load inverter and upender, including loading, turning, and unloading. The key features and benefits of the product are highlighted, such as its ability to handle heavy loads up to 20,000 pounds, its user-friendly interface, and its safety features.

At [company name], we are committed to providing top-quality products and services to our clients. With our load inverter and upender, you can save time, effort, and money, as well as increase productivity and efficiency.

Don’t forget to like, subscribe, and share this video with your colleagues and friends! For more information, visit our website [website link] or contact us at [email address].

Additional tags and keywords: load inverter, upender for pallet, heavy load turning, coil upender, 180 degree turning, logistics, construction, manufacturing.

Hashtags: #loadinverter #upenderforpallet #heavyloadturning #coilupender #180degreeturning #logistics #construction #manufacturing.

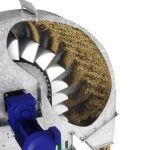

Here is a possible tilter and upender design for pallet and heavy load package 180 degree turning:

1. Frame: Construct a strong steel frame to support the tilter and upender mechanism. The frame should have a base with forklift pockets for easy transportation.

2. Tilter mechanism: Install a hydraulic cylinder or electric motor to power the tilting mechanism. The cylinder should be able to lift and tilt the load up to 180 degrees. Use high-quality seals and hoses to prevent leaks and ensure smooth operation. The tilter should have adjustable stops to hold the load securely in place during tilting.

3. Upender mechanism: Install a set of powered rollers or conveyor belts to aid the upending process. The rollers should be adjustable to fit different load sizes and have a non-slip surface to prevent load slippage. The upender should have adjustable stops to hold the load securely in place during upending.

4. Control system: Install a control panel with push buttons or a remote control to operate the tilter and upender mechanism. The control system should have safety features such as emergency stop buttons and overload protection.

5. Optional features: Depending on the application, you can add optional features such as a weighing scale, a label printer, or a barcode scanner to the tilter and upender system.

Overall, this tilter and upender system should be designed for heavy-duty use and able to handle loads up to several tons. Regular maintenance and inspections should be performed to ensure safe and reliable operation. coil upender

#inverter #upender #pallet #heavy #load #package #degree #turning