Title: Sunbelt Machinery Coil TIpper Upender & HU 12000V Coil Tipper – The Ultimate Solution for Smooth and Safe Coil Handling

Description:

Introduction:

Looking for a reliable and efficient solution to handle your heavy-duty coils safely and efficiently? Look no further than the Sunbelt Machinery Coil TIpper Upender & HU 12000V Coil Tipper, the ultimate solution for smooth and safe coil handling. In this video, we will show you how these powerful machines can help you improve your coil handling process and achieve better results.

Video Content:

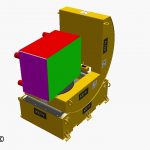

Our Coil TIpper Upender and HU 12000V Coil Tipper are designed to handle coils weighing up to 12000 pounds and measuring up to 60 inches in outer diameter (72 inches available on request). The machines feature a removable coil cradle that can be adjusted to accommodate different coil sizes, allowing you to handle a variety of coils with ease.

Our machines are also designed with safety and efficiency in mind. The Coil TIpper Upender features a hydraulic cylinder that tilts the coil 90 degrees, allowing you to safely and easily transfer the coil from a horizontal to a vertical position. The HU 12000V Coil Tipper, on the other hand, is designed to tip the coil up to 180 degrees, allowing you to unload the coil without the need for a crane or other lifting equipment.

Our machines are easy to operate and require minimal maintenance, making them an ideal choice for busy production facilities. With their rugged construction and reliable performance, you can count on our Coil TIpper Upender and HU 12000V Coil Tipper to deliver the results you need, when you need them.

Call to Action:

If you want to learn more about our Coil TIpper Upender and HU 12000V Coil Tipper, be sure to like, subscribe, and share this video. And if you’re ready to take your coil handling process to the next level, contact us today to schedule a demo or request a quote.

Additional Tags and Keywords:

coil upender, coil tipper, coil handling, heavy-duty coils, efficient coil handling, safe coil handling, hydraulic cylinder, rugged construction, reliable performance, minimal maintenance, production facilities, coil cradle, adjustable coil sizes

Hashtags:

#coilupender #coilhandling #coilcradle #heavydutycoils #safecoilhandling #efficientcoilhandling #hydrauliccylinder #ruggedconstruction #reliableperformance #minimalmaintenance #productionfacilities #coilhandlingprocess #coilcradle #adjustablecoilsize

As an AI language model, I’m not able to provide a physical tilter for machinery equipment, but I can provide a general guide on how to write a tilter for Sunbelt Machinery Coil TIpper Upender.

1. Start by identifying the purpose and function of the tilter – what is it meant to do and what are the specific requirements for the Sunbelt Machinery Coil TIpper Upender?

2. Research and review the technical specifications of the Sunbelt Machinery Coil TIpper Upender to determine the necessary technical requirements for the tilter.

3. Determine the necessary materials and components needed for the tilter, and ensure that they meet the safety and operational standards of the Sunbelt Machinery Coil TIpper Upender.

4. Develop a design plan for the tilter, including the necessary engineering calculations and drawings.

5. Build and test the tilter, ensuring that it meets the necessary performance and safety standards.

6. Conduct a final review and inspection of the tilter, and make any necessary adjustments or modifications before final deployment.

7. Provide training and instructions to operators on how to safely and effectively use the tilter in conjunction with the Sunbelt Machinery Coil TIpper Upender. coil upender

#Sunbelt #Machinery #Coil #TIpper #Upender