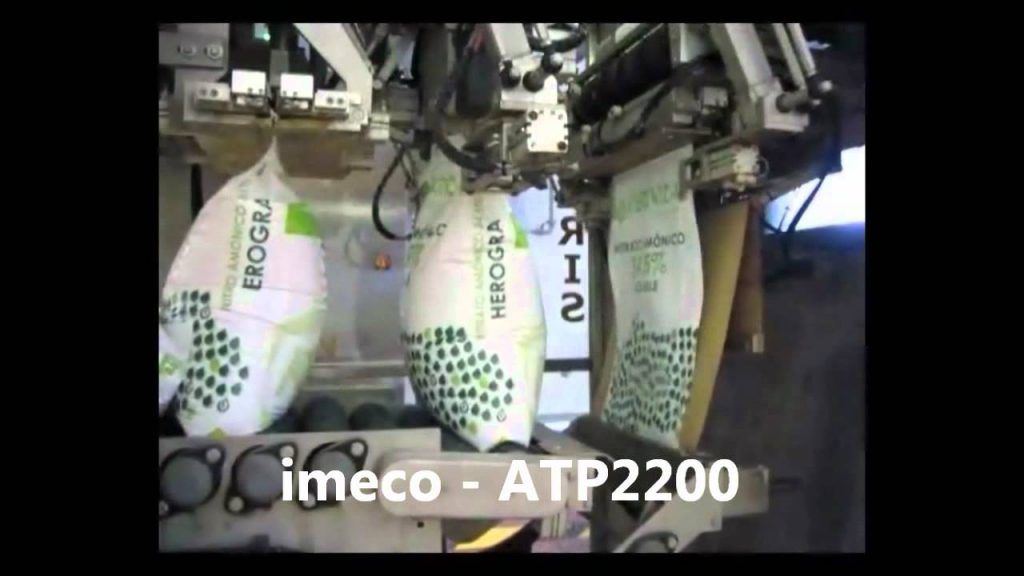

Title: Advanced Bagging Packing Line: imeco ATP2200 FFS Automatic Bagging System [Fertilizer]

Description:

Welcome to our video showcasing the remarkable capabilities of the Automatic Bagging Packing Line – imeco ATP2200 FFS Automatic Bagging System for various applications, including fertilizer, salt, and more. This cutting-edge bagging line is designed to efficiently form, fill, and seal bags made from a reel of tubular thermoplastics material.

Introduction:

In this video, we present the imeco ATP2200 FFS Automatic Bagging System, a state-of-the-art solution for streamlining bagging processes. Whether you are in the fertilizer industry, dealing with salt distribution, or handling other similar materials, this advanced bagging line offers unparalleled efficiency and reliability.

Video Content:

Our video provides a comprehensive overview of the key features and operation steps of the Automatic Bagging Packing Line – imeco ATP2200 FFS Automatic Bagging System. Here are the main highlights:

1. Forming Bags with Precision:

The bagging line utilizes tubular thermoplastics material, enabling it to create bags of varying sizes with ease. This flexibility ensures optimal packaging for different product quantities and dimensions, enhancing your operational efficiency.

2. Efficient Filling Mechanism:

With its automated filling mechanism, the imeco ATP2200 FFS Bagging System ensures accurate and consistent filling of bags. This eliminates wastage and reduces the need for manual intervention, saving you time and resources.

3. Reliable Sealing Technology:

Sealing bags securely is crucial in preventing product leakage and ensuring long-lasting freshness. Our bagging system incorporates advanced sealing technology, guaranteeing reliable and airtight seals for every bag.

4. Versatility for Various Applications:

The imeco ATP2200 FFS Automatic Bagging System is specifically designed to handle a wide range of materials, including fertilizers, salts, and more. Its adaptability makes it an ideal choice for industries requiring diverse bagging solutions.

Call to Action:

If you found this video informative and insightful, please consider liking, subscribing, and sharing it with others who might benefit from this advanced bagging system.

Additional Tags and Keywords: automatic bagging system, bagging line, bagging machine, fertilizer bagging, salt bagging, packaging solution, thermoplastics bagging, efficient bagging.

Hashtags: #AutomaticBaggingSystem #imecoATP2200 #FFSBaggingLine #FertilizerBagging #SaltBagging #EfficientPackaging

To write a tilter for the Imeco ATP2200 FFS automatic bagging line for fertilizer, you would need to consider the specific requirements and functionality of the tilter. Here is a general outline of the tilter’s code:

1. Initialize the tilter and establish communication with the ATP2200 bagging line’s control system.

2. Set up the necessary sensors and actuators for the tilter, such as limit switches or proximity sensors to detect the position of the bags.

3. Create a loop to continuously monitor the bagging line and perform the tilting operation when required.

4. Inside the loop, use the sensors to detect the presence of a filled bag on the conveyor belt.

5. Once a filled bag is detected, activate the tilting mechanism to tilt the bag at the desired angle.

6. Use the appropriate motor or actuator to control the tilting motion, ensuring smooth and controlled movement.

7. Monitor the tilt angle to ensure it reaches the desired position and adjust if necessary.

8. Once the bag is tilted, wait for a specified time to allow the product to settle or drain inside the bag.

9. After the specified time, return the bag to its original position by reversing the tilting motion.

10. Continue monitoring the bagging line for further bags and repeat the tilting process as needed.

11. Implement error handling and safety measures, such as emergency stop functionality or error notifications, to ensure the tilter operates safely and efficiently.

12. Finally, close the communication with the bagging line’s control system and properly shutdown the tilter when required.

Note: This is a general outline, and the actual implementation may vary depending on the specific requirements and capabilities of the Imeco ATP2200 FFS automatic bagging line and the tilter system. It is recommended to consult the equipment’s documentation and work closely with the manufacturer or a qualified engineer to develop a reliable and safe tilter solution. coil packing line

#imeco #ATP2200 #FFS #automatic #bagging #line #fertilizer