Title: “Efficient and Reliable Automatic Labeling Machine – Assemble and Operate Label Machine Semi-Automatic MT50 ML50 MY50 from China”

Description:

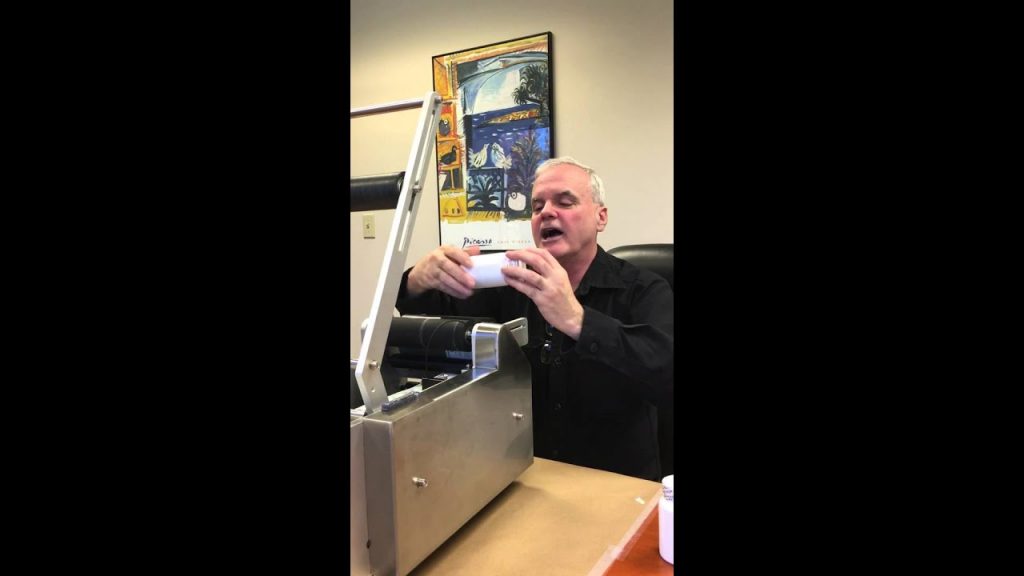

Welcome to Pilgrims Promise, your trusted source for high-quality labeling machines. In this video, we present the Automatic Labeling Machine, specifically the MT50 ML50 MY50 models, which are designed to streamline your labeling process and enhance productivity.

Introduction:

In this comprehensive video, we provide you with a detailed overview of the Automatic Labeling Machine, its assembly process, and step-by-step instructions on operating it efficiently. Whether you are a small business owner, a production manager, or an entrepreneur looking to optimize your labeling operations, this video is a valuable resource for you.

Video Content:

1. Key Features: Discover the remarkable features of the Automatic Labeling Machine, including its user-friendly interface, high precision labeling, and versatile compatibility with various label sizes and materials.

2. Assembly Instructions: Follow our expert guidance as we demonstrate the simple and hassle-free assembly process of the Label Machine. Learn how to set it up efficiently and ensure smooth operation.

3. Operation Steps: Gain valuable insights into the operation of the Label Machine. We cover essential steps, such as loading labels, adjusting settings, and troubleshooting common issues, making it easy for you to achieve optimal labeling results.

4. Benefits and Applications: Explore the diverse range of industries and applications that can benefit from the Automatic Labeling Machine. From food packaging to pharmaceutical labeling, this machine offers exceptional versatility and efficiency.

Call to Action:

If you found this video helpful, don’t forget to hit the like button, subscribe to our channel for more informative content, and share this video with others who might benefit from it. Visit our website for additional information and to explore our extensive range of labeling machines.

Additional Tags and Keywords:

Automatic Labeling Machine, Label Machine, MT50, ML50, MY50, Semi-Automatic Labeling Machine, China, labeling process, productivity, assembly process, operating instructions, high precision labeling, label sizes, versatile compatibility, user-friendly, troubleshooting, benefits, applications.

Hashtags:

#AutomaticLabelingMachine #LabelMachine #MT50 #ML50 #MY50 #SemiAutomatic #Productivity #China #LabelingProcess #AssemblyInstructions #OperationSteps #Efficiency

Title: Comprehensive Guide for Assembling and Operating the Semi-Automatic Label Machine MT50, ML50, and MY50 from China

Introduction:

The following guide aims to provide step-by-step instructions for assembling and operating the semi-automatic label machines MT50, ML50, and MY50 manufactured in China. These machines are commonly used for labeling various products in industries such as packaging, manufacturing, and logistics. By following this guide, users will be able to assemble the machine correctly and efficiently operate it to achieve optimal labeling results.

Table of Contents:

1. Safety Precautions

2. Assembling the Label Machine

2.1 Unpacking and Inspection

2.2 Assembling the Stand

2.3 Installing the Label Dispenser and Roll Holder

2.4 Connecting Power Supply and Adjusting Voltage Settings

2.5 Securing the Machine

3. Operating the Label Machine

3.1 Powering On and Initial Setup

3.2 Loading the Label Roll

3.3 Adjusting Label Positioning

3.4 Setting Label Length

3.5 Adjusting Label Sensor

3.6 Label Dispensing and Application

3.7 Troubleshooting Common Issues

1. Safety Precautions:

Before starting the assembly or operation of the label machine, it is crucial to adhere to the following safety precautions:

– Ensure the machine is powered off and unplugged during assembly and maintenance.

– Avoid wearing loose clothing or accessories that may get caught in the machine’s moving parts.

– Keep hands and fingers clear of any rotating or moving components.

– Familiarize yourself with emergency stop procedures and the location of the emergency stop button.

– Read and understand the user manual provided by the manufacturer for additional safety information.

2. Assembling the Label Machine:

2.1 Unpacking and Inspection:

– Carefully unpack the label machine and inspect all components for any signs of damage during transportation.

– Verify that all parts and accessories mentioned in the user manual are included in the package.

2.2 Assembling the Stand:

– Follow the provided instructions to assemble the stand using the provided nuts, bolts, and tools.

– Ensure the stand is stable and securely fastened.

2.3 Installing the Label Dispenser and Roll Holder:

– Attach the label dispenser to the stand according to the manufacturer’s instructions.

– Install the roll holder and adjust it to accommodate the label roll size.

2.4 Connecting Power Supply and Adjusting Voltage Settings:

– Connect the label machine to a suitable power source as specified in the user manual.

– Set the appropriate voltage on the machine’s control panel or switch according to your region’s power supply.

2.5 Securing the Machine:

– Once the machine is assembled, ensure all components are tightened and secured properly.

– Perform a final inspection to ensure there are no loose parts that may interfere with the machine’s operation.

3. Operating the Label Machine:

3.1 Powering On and Initial Setup:

– Plug in the machine and switch it on according to the manufacturer’s instructions.

– Familiarize yourself with the control panel and its functions.

– Perform any initial setup, such as adjusting language settings or calibrating the machine if required.

3.2 Loading the Label Roll:

– Open the label dispenser and place the label roll onto the roll holder.

– Thread the label web through the machine’s feeding mechanism as per the user manual’s instructions.

3.3 Adjusting Label Positioning:

– Use the control panel or adjustment knobs to align the label’s position in relation to the dispensing mechanism.

– Verify that the label is centered and positioned correctly for accurate application.

3.4 Setting Label Length:

– Adjust the label length settings using the control panel or adjustment knobs to match your labeling requirements.

3.5 Adjusting Label Sensor:

– Ensure the label sensor is properly aligned with the label web.

– Follow the manufacturer’s instructions to adjust the sensor’s sensitivity if necessary.

3.6 Label Dispensing and Application:

– Use the appropriate controls on the machine to initiate the label dispensing and application process.

– Verify that the labels are being dispensed and applied accurately and consistently.

3.7 Troubleshooting Common Issues:

– Consult the user manual for troubleshooting guidance in case of any issues during operation.

– Contact the manufacturer’s customer support for further assistance if required.

Conclusion:

By following this comprehensive guide, users will be able to successfully assemble and operate the semi-automatic label machines MT50, ML50, and MY50 from China. Adhering to safety precautions, proper assembly, and understanding the operational steps will ensure efficient and reliable labeling results, contributing to a streamlined production process.Labeling Machine

#Assemble #operate #Label #Machine #semi #automatic #MT50 #ML50 #MY50 #China