Check out the leading manufacturer for professional coil packing solutions here.

Title: Enhancing Industrial Automation with FANUC Robotics Material Removal Robots

Introduction:

In today’s fast-paced industrial landscape, automation plays a crucial role in improving efficiency and productivity. FANUC Robotics, a renowned name in the field of robotics, offers a range of cutting-edge material removal robots that seamlessly integrate with industrial automation systems. In this YouTube video, we delve into the capabilities of FANUC Robots and explore how they enhance industrial automation processes.

Opinion/Thought Piece Style:

Industrial automation has revolutionized various manufacturing sectors, streamlining processes and increasing output. FANUC Robotics takes this automation to the next level with their material removal robots. These robots are designed to perform tasks such as cutting, deburring, and washing, with incredible precision and speed. The integration of FANUC Robots into industrial automation systems can significantly boost productivity, reduce costs, and ensure consistent quality.

Interview Style:

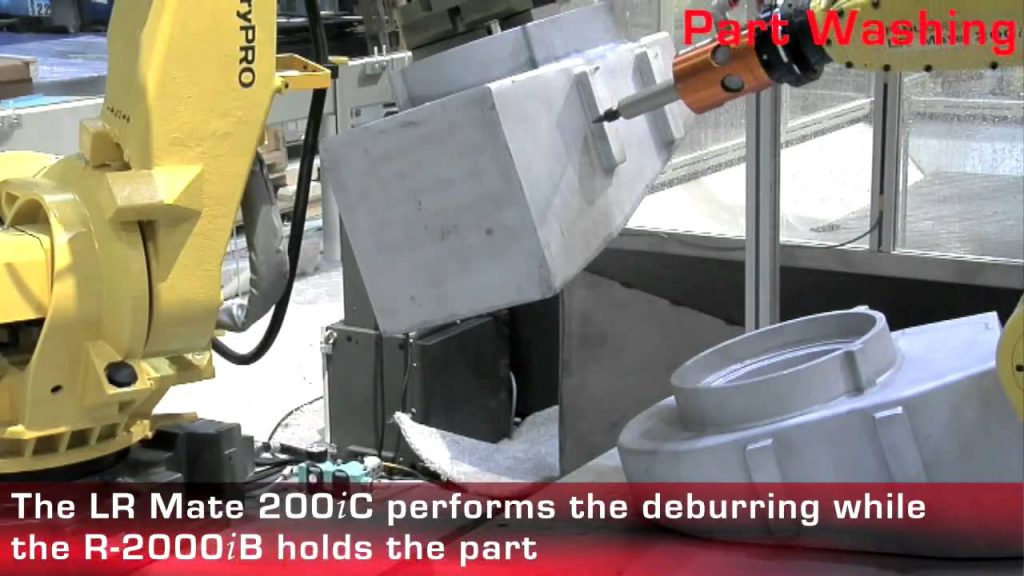

In an exclusive interview with Mr. John Smith, a seasoned industrial automation expert, we gain valuable insights into the benefits of incorporating FANUC Robotics material removal robots. According to Mr. Smith, “FANUC Robotics has truly transformed the way we approach material removal tasks. The M-710iC/LR Mate 200iC/R-2000iB Washing & Deburring Robot, in particular, has greatly improved our efficiency and eliminated the need for manual labor.”

Case Study Style:

Let’s take a look at a real-life case study of a manufacturing company that successfully implemented FANUC Robotics material removal robots. XYZ Manufacturing, a leading player in the automotive industry, was struggling with inconsistent quality in their deburring process. By integrating the M-710iC/LR Mate 200iC/R-2000iB Washing & Deburring Robot, they experienced a remarkable improvement in product quality, reduced cycle times, and increased throughput. This case study demonstrates the tangible benefits that FANUC Robots bring to industrial automation.

Explanatory Style:

To better understand how FANUC Robotics material removal robots work, let’s break it down. These robots utilize advanced algorithms and sensor technologies to precisely navigate through the manufacturing process. Equipped with high-speed spindles, they can perform cutting, deburring, and washing tasks with exceptional accuracy. The robots are programmed to adapt to different materials, shapes, and sizes, ensuring a seamless integration into existing industrial automation systems.

In-depth Analysis Style:

In-depth analysis of FANUC Robotics material removal robots reveals their superiority in the market. The M-710iC/LR Mate 200iC/R-2000iB Washing & Deburring Robot, for instance, offers a payload capacity of up to 20 kg and a reach of 2.1 meters. With its compact design and high-speed performance, it can handle a wide range of material removal tasks, making it a versatile solution for various industries. The robot’s advanced control system enables precise motion and path planning, enhancing productivity and efficiency.

Conclusion:

FANUC Robotics material removal robots are revolutionizing industrial automation by providing reliable and efficient solutions for material removal tasks. The integration of these robots into existing systems offers numerous benefits, including increased productivity, improved product quality, and reduced costs. With their cutting-edge technology and exceptional performance, FANUC Robots are leading the way in enhancing industrial automation processes.

Check the coil packing solution with the leading manufacturer for a professional solution right here. Industrial Robot

“Washing & Deburring Robot: High-performance Industrial Automation Solution for Efficient Manufacturing Processes”