Check out our leading manufacturer for the best coil packing solution. We provide professional solutions tailored to your specific needs. Contact us today to find out more!

—

Title: Enhancing Efficiency and Precision with Semi-Automatic Plastic Injection Machines

Introduction:

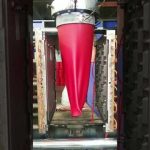

In today’s fast-paced manufacturing industry, optimizing production processes is crucial for businesses to stay competitive. One such innovation that has revolutionized the plastic molding industry is the semi-automatic plastic injection machine. This advanced technology offers enhanced efficiency and precision, making it an indispensable tool for manufacturers worldwide. In this article, we will explore the features and benefits of a semi-automatic plastic injection machine and how it can revolutionize your production line.

Section 1: The Evolution of Plastic Injection Machines

In the early days of plastic molding, manual labor was the primary method used. However, with the advent of technology, semi-automatic plastic injection machines were introduced. These machines automate various aspects of the injection molding process, eliminating the need for manual intervention and reducing the risk of errors. The integration of advanced control systems, hydraulics, and electronics has made these machines more efficient, accurate, and reliable.

Section 2: Key Features of Semi-Automatic Plastic Injection Machines

Semi-automatic plastic injection machines are equipped with a range of features that enhance their performance and productivity. Some notable features include:

1. Precise Control System: These machines come with advanced control systems that allow for precise control over various parameters such as injection speed, pressure, and temperature. This ensures consistent and accurate molding results.

2. User-Friendly Interface: The user interface of these machines is designed to be intuitive and user-friendly. Operators can easily set and adjust parameters, monitor the process, and troubleshoot any issues, thereby minimizing downtime.

3. Versatility: Semi-automatic plastic injection machines are capable of molding a wide range of plastic products, from small components to large containers. This versatility makes them suitable for various industries, including automotive, packaging, electronics, and more.

4. Energy Efficiency: These machines are designed to optimize energy consumption, resulting in lower operational costs. They utilize advanced technologies such as servo motors and variable pump systems to reduce energy wastage, making them an environmentally friendly choice.

Section 3: Advantages of Semi-Automatic Plastic Injection Machines

Investing in a semi-automatic plastic injection machine offers numerous advantages for manufacturers. Some key benefits include:

1. Improved Efficiency: By automating the injection molding process, these machines significantly increase production efficiency. They can operate continuously with minimal downtime, leading to higher output and faster turnaround times.

2. Enhanced Precision: The precise control system of these machines ensures consistent molding results with minimal variations. This leads to higher product quality, reduced waste, and lower rejection rates.

3. Cost-Effective: Semi-automatic plastic injection machines offer a cost-effective solution for small to medium-scale production. They require less initial investment compared to fully automatic machines while still providing high-quality results.

4. Flexibility: These machines offer flexibility in terms of mold changes and customization. Manufacturers can easily switch between different molds to produce various products, allowing for greater adaptability to market demands.

Section 4: Conclusion

Semi-automatic plastic injection machines have transformed the plastic molding industry, offering improved efficiency, precision, and cost-effectiveness. By investing in this advanced technology, manufacturers can optimize their production processes, enhance product quality, and gain a competitive edge in the market. If you’re looking for the best coil packing solution, our leading manufacturer is here to provide you with professional and tailored solutions. Contact us today to revolutionize your production line! Plastic Injection Machine

“Efficient Plastic Moulding Machines for Bihar & Morbi | Semi-Automatic Vertical Injection & Screw Type”