Packaging machines, such as Vertical Form Fill Seal (VFFS), are crucial in maintaining high performance and precision in the packaging industry. These machines are highly cyclic, meaning they are designed to handle repetitive and demanding tasks with utmost efficiency. In this article, we will explore the use of Industrial Filling Packing Machines and their integration with ABB servo drives, providing a comprehensive understanding of their functionality and benefits.

Industrial Filling Packing Machines play a significant role in the packaging process, ensuring products are efficiently and accurately filled and sealed. These machines are widely used in various industries, including food and beverage, pharmaceuticals, cosmetics, and more. They offer a reliable and automated solution for packaging bulk quantities of products, improving productivity and reducing manual labor.

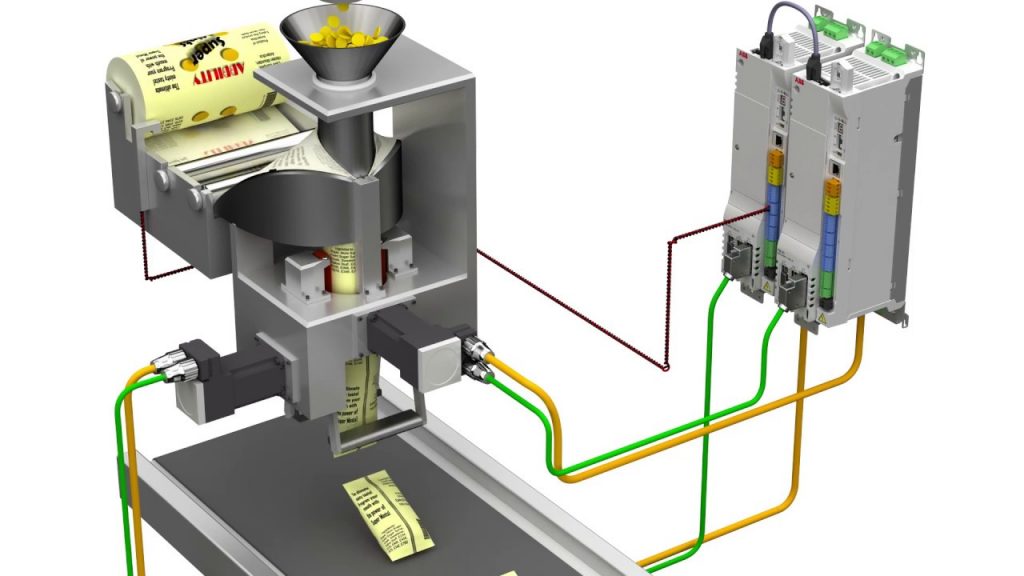

One of the key components that enhance the performance of Industrial Filling Packing Machines is the integration of ABB servo drives. ABB servo drives are advanced motion control devices that provide precise and accurate control of the packaging process. These drives offer high-speed and high-precision operation, ensuring consistent and reliable packaging results. By utilizing ABB servo drives, packaging machines can achieve faster cycle times, reduce waste, and increase overall efficiency.

The Vertical Form Fill Seal (VFFS) is a specific type of packaging machine that is widely employed in the industry. It offers a versatile solution for packaging various types of products, including powders, granules, liquids, and solids. The VFFS machine forms a pouch from a roll of packaging material, fills it with the product, and then seals it to create a finished package. The integration of ABB servo drives in VFFS machines allows for precise control of the bag forming, filling, and sealing operations, ensuring accurate and consistent packaging.

The use of Industrial Filling Packing Machines with ABB servo drives brings several advantages to the packaging industry. Firstly, these machines offer improved efficiency, enabling higher production rates and reducing downtime. The precise control provided by ABB servo drives ensures that each package is filled accurately, minimizing product wastage and ensuring consistency in the packaging process.

Additionally, the integration of ABB servo drives in packaging machines results in enhanced flexibility and versatility. The machines can easily adapt to different packaging requirements, allowing for quick changeovers between different products or packaging sizes. This flexibility is especially valuable in industries where multiple products or variations need to be packaged.

Furthermore, the use of ABB servo drives contributes to improved overall equipment effectiveness (OEE) in packaging operations. By optimizing the packaging process and minimizing errors, these drives help increase the productivity and profitability of packaging lines.

In conclusion, Industrial Filling Packing Machines, particularly those utilizing ABB servo drives, play a crucial role in the packaging industry. They offer high performance and precision, ensuring efficient and accurate packaging of various products. The integration of ABB servo drives in Vertical Form Fill Seal (VFFS) machines enhances their functionality and enables precise control over the packaging process. By utilizing these advanced technologies, businesses can experience improved efficiency, flexibility, and overall equipment effectiveness. Check the coil packing solution with leading manufacturer for the professional solution just here. Filling Packing Machine

“Efficient Packaging: Enhancing Vertical Form Fill Seal (VFFS) with ABB Servo Drives and Industrial Filling Packing Machine”