Title: Efficient and Versatile Automatic Food Packing Machine for Ready-to-Eat Meals | YouTube Video Ranking

Description:

Introduction:

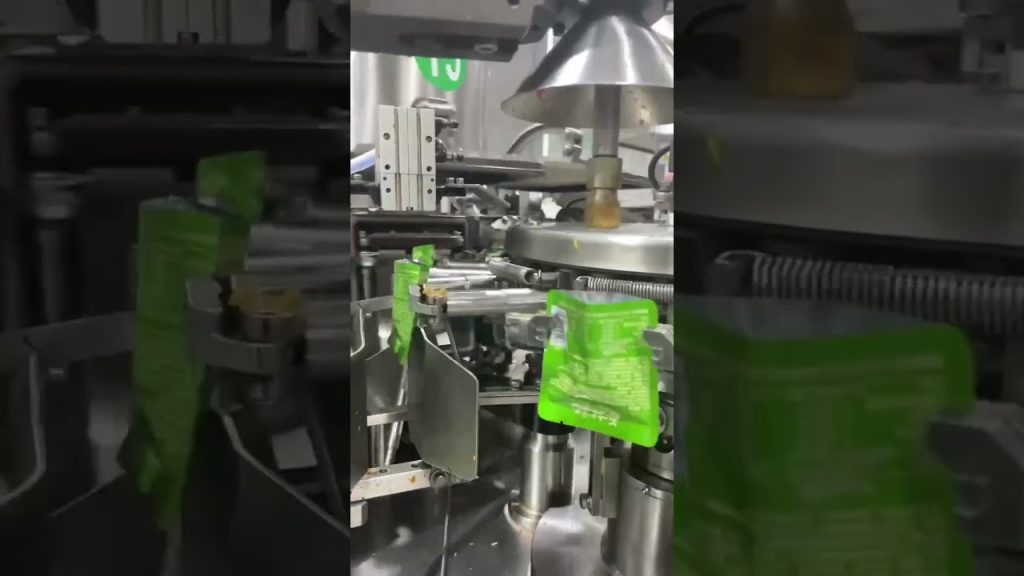

Welcome to our YouTube video showcasing the exceptional capabilities of the Automatic Food Packing Machine, specifically designed for efficient and hygienic packaging of ready-to-eat meals. In this video, we will provide a comprehensive overview of this cutting-edge machine, highlighting its features, benefits, and operation steps. Stay tuned to discover how this innovative packaging solution can revolutionize your food production process.

Video Content:

The Automatic Food Packing Machine is a state-of-the-art technology that offers seamless integration into your food production line. With its advanced vacuum packaging system, it ensures freshness, extends shelf life, and preserves the nutritional value of ready-to-eat meals. This machine is designed to meet the demanding requirements of the food industry, providing high-speed and accurate packaging without compromising on quality.

Key Features:

1. Versatile Packaging: The Automatic Food Packing Machine offers flexible packaging options, accommodating a wide range of ready-to-eat meals, including sandwiches, salads, wraps, and more.

2. Efficiency and Speed: With its automated processes, this machine significantly increases production efficiency, reducing labor costs and minimizing packaging time.

3. Advanced Vacuum Technology: The vacuum packaging system eliminates oxygen from the packaging, preventing spoilage, and maintaining the food’s freshness and flavor.

4. Precise Portion Control: The machine ensures consistent portion sizes, allowing for uniform product presentation and improved customer satisfaction.

5. User-Friendly Interface: The intuitive control panel enables easy operation and quick adjustments for different packaging requirements.

6. Hygienic Design: The machine is constructed with food-grade stainless steel, ensuring compliance with strict hygiene standards and facilitating easy cleaning and maintenance.

Operation Steps:

1. Prepare the packaging material and load it into the machine.

2. Set the desired packaging parameters using the user-friendly interface.

3. Place the ready-to-eat meals on the conveyor belt for automatic packaging.

4. The machine will seal the packaging, remove excess air with the vacuum system, and provide airtight packaging.

5. The packaged meals are then ready for distribution and storage.

Call to Action:

If you’re in the food industry and looking to enhance your production efficiency and maintain the quality of your ready-to-eat meals, the Automatic Food Packing Machine is the ideal solution for you. Like, subscribe, and share this video to stay updated with the latest packaging technologies. Don’t forget to leave your comments and questions below.

Additional Tags and Keywords: automatic food packing machine, ready-to-eat food packaging, vacuum packaging machine, food industry, packaging technology, efficient packaging, hygienic design, high-speed packaging, portion control.

Hashtags: #foodpackingmachine #readytoeatpackaging #vacuumpackaging #foodindustry #packagingtechnology #efficiency #hygienicdesign

Here’s a sample tilter for an Automatic Ready to eat food Vacuum packaging machine:

Title: Automatic Ready-to-Eat Food Vacuum Packaging Machine Tilter

Introduction:

The Automatic Ready-to-Eat Food Vacuum Packaging Machine Tilter is a revolutionary piece of equipment designed to streamline the packaging process for ready-to-eat food items. This tilter is specifically engineered to enhance efficiency, accuracy, and productivity in the food packaging industry. By automating the tilting process, it eliminates the need for manual labor, reduces the risk of errors, and ensures consistent packaging quality.

Features:

1. Automatic Tilting Mechanism: The tilter is equipped with a state-of-the-art automated tilting mechanism, which efficiently transfers ready-to-eat food items from the conveyor belt to the packaging chamber. This eliminates the need for manual handling, reducing the risk of contamination and improving overall hygiene.

2. Adjustable Angle Settings: The tilter offers adjustable angle settings to cater to various packaging requirements. With customizable tilting angles, it can accommodate different food product sizes and shapes, ensuring optimal packaging efficiency.

3. Precise Control System: The tilter is integrated with a precise control system that allows operators to accurately set the desired tilt angle, speed, and timing. This ensures consistent and uniform packaging results, minimizing the risk of product damage or spoilage.

4. Easy Integration: The tilter is designed for easy integration with existing conveyor systems, making it a seamless addition to your packaging line. Its compact design saves valuable floor space and enhances overall workflow efficiency.

5. User-Friendly Interface: The tilter features a user-friendly interface, equipped with a touch screen control panel. This intuitive interface allows operators to easily monitor and adjust the machine settings, simplifying operation and minimizing training requirements.

6. Safety Measures: The tilter is equipped with various safety features to protect both operators and the machine. These include emergency stop buttons, safety sensors, and protective guards, ensuring a secure working environment.

Benefits:

1. Increased Efficiency: The automation of the tilting process significantly improves packaging speed and efficiency, reducing overall production time and increasing output.

2. Enhanced Productivity: By eliminating manual labor, the tilter allows operators to focus on other crucial tasks, increasing overall productivity and output.

3. Improved Product Quality: The precise control system and adjustable angle settings ensure consistent packaging quality, reducing the risk of product damage or spoilage.

4. Hygienic Packaging: The automated tilting mechanism eliminates manual handling, minimizing the risk of contamination and ensuring hygienic packaging.

5. Cost Savings: The tilter reduces labor costs and minimizes product waste, resulting in significant cost savings for the food packaging industry.

Conclusion:

The Automatic Ready-to-Eat Food Vacuum Packaging Machine Tilter is a game-changer in the food packaging industry. Its automated tilting mechanism, adjustable angle settings, and precise control system enhance efficiency, productivity, and product quality. By investing in this tilter, food packaging companies can streamline their operations, reduce costs, and deliver superior ready-to-eat food products to consumers.Food Packing Machine

#Automatic #Ready #eat #food #Vacuum #packaging #machine