Welcome to the world of Full-service Custom Plastic Injection Molding and Tooling! In this YouTube video, we will take you on a journey from concept to manufacture, exploring the intricate process of creating high-quality plastic products. Whether you are a curious individual or a business owner looking for manufacturing solutions, this video is for you.

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. It is a versatile technique that allows for the production of complex and intricate shapes with high precision. From automotive parts to medical devices, plastic injection molding plays a crucial role in various industries.

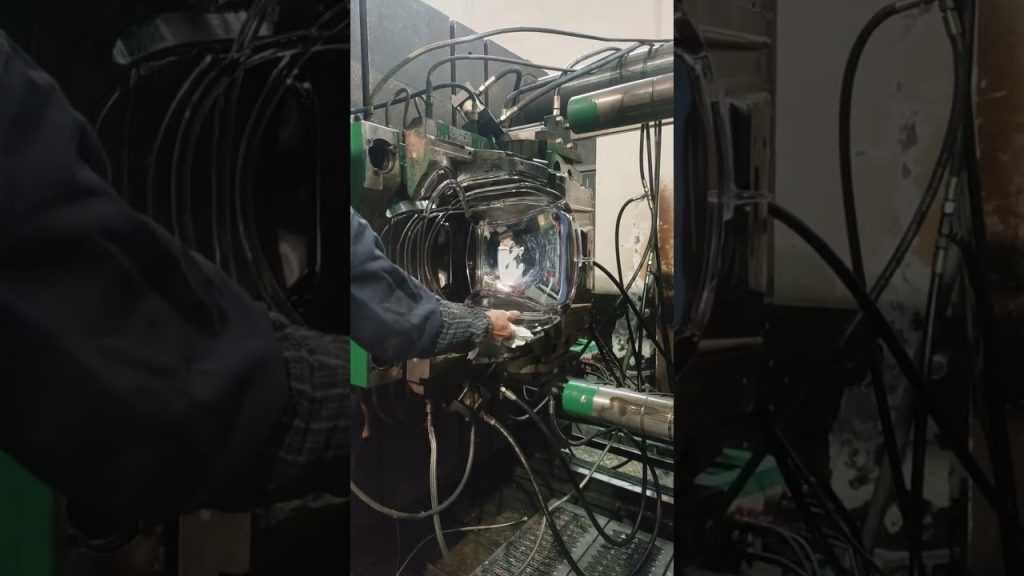

At the heart of this process lies the Industrial Plastic Injection Machine. This powerful machine, equipped with state-of-the-art technology, ensures the smooth and efficient production of plastic parts. It is capable of handling different types of plastics and can produce large quantities of products within a short period.

One of the key applications of the Industrial Plastic Injection Machine is the production of clear PC/transparent chairs. These chairs are not only aesthetically pleasing but also highly durable and versatile. The injection molding process allows for the creation of chairs that are both comfortable and visually appealing.

Now, let’s delve into the step-by-step process of Full-service Custom Plastic Injection Molding and Tooling. From concept to manufacture, each stage requires meticulous attention to detail and expertise.

1. Concept Development: This is where the journey begins. The design team works closely with the client to understand their requirements and vision. With the help of advanced software, they create a 3D model of the desired product, ensuring that every aspect is taken into consideration.

2. Mold Design and Manufacturing: Once the concept is finalized, the next step is to design and manufacture the mold. This is a crucial stage as the mold determines the quality and precision of the final product. Skilled engineers use cutting-edge technology to create molds that are tailored to the specific requirements of the product.

3. Material Selection: Choosing the right material is vital for the success of the project. The team carefully selects the appropriate plastic resin based on factors such as strength, durability, and appearance. They ensure that the chosen material is compatible with the Industrial Plastic Injection Machine.

4. Injection Molding: This is where the magic happens. The mold is loaded into the Industrial Plastic Injection Machine, and the selected plastic resin is melted and injected into the mold cavity under high pressure. The machine meticulously controls temperature, pressure, and cooling time to ensure the perfect formation of the product.

5. Quality Assurance: Every product goes through a rigorous quality assurance process to ensure that it meets the highest standards. Skilled technicians inspect each piece for any defects or imperfections, and any necessary adjustments are made to the process.

6. Packaging and Delivery: Once the products pass the quality assurance tests, they are carefully packaged and prepared for delivery. The team ensures that they are properly protected during transportation to prevent any damage.

Full-service Custom Plastic Injection Molding and Tooling is a complex process that requires expertise, precision, and attention to detail. It is a testament to the capabilities of modern manufacturing technology and the dedication of skilled professionals.

In conclusion, the Industrial Plastic Injection Machine plays a crucial role in the production of high-quality plastic products. From concept to manufacture, the process of Full-service Custom Plastic Injection Molding and Tooling ensures that every product meets the highest standards of quality and precision.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Plastic Injection Machine

“Efficient Injection Molding Techniques for Clear PC and Transparent Chair Production Utilizing Industrial Plastic Injection Machines”