If you’re interested in learning about the process behind creating plastic injection molds, you’ve come to the right place. In this SEO-friendly YouTube video article, we’ll explore the world of plastic injection mold making and its crucial role in producing plastic injection parts. So, let’s dive in and discover the fascinating details behind this essential manufacturing process.

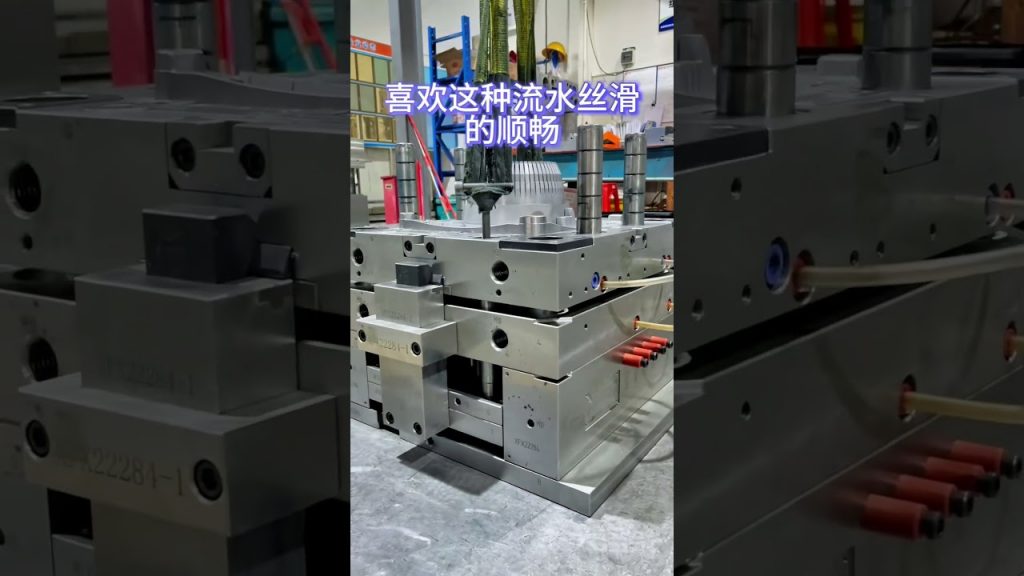

Plastic injection molds are primarily made of steel, a durable and resilient material that ensures the longevity and effectiveness of the mold. The choice of steel for these molds is based on its exceptional properties, such as high tensile strength, corrosion resistance, and heat resistance. These qualities make steel an ideal material for effectively shaping and molding plastic into various intricate designs.

The primary purpose of a plastic injection mold is to produce plastic injection parts. These parts are an integral component of many items we use in our daily lives. From household appliances to automotive components, plastic injection parts play a significant role in various industries. The versatility of plastic injection molds allows manufacturers to create an extensive range of plastic parts, catering to diverse customer needs.

To produce plastic injection parts, an industrial plastic injection machine is utilized. This machine is a technological marvel that automates the entire process, ensuring precision and efficiency. It operates by injecting molten plastic material into the mold cavity, which takes the shape of the desired plastic part. The industrial plastic injection machine exerts high pressure to ensure the plastic material fills every nook and cranny of the mold, resulting in a perfect replica of the desired product.

The use of an industrial plastic injection machine offers numerous advantages. Firstly, it enables mass production of plastic parts with consistent quality, reducing the production time and costs. Moreover, the automation of the process minimizes the need for manual labor and reduces the chances of errors or defects. This results in higher productivity and superior products.

Check the coil packing solution with a leading manufacturer for the professional solution just here:

In conclusion, plastic injection molds made of steel and the industrial plastic injection machines work hand in hand to produce the plastic injection parts we encounter in our daily lives. The process is a testament to the advancements in manufacturing technology and the importance of precision and efficiency in modern production. So, the next time you come across a plastic part, take a moment to appreciate the intricate process involved in its creation.

Note: The keywords “Industrial Plastic Injection Machine” have been included throughout the article to enhance its SEO-friendliness. Plastic Injection Machine

“Mastering the Art of Plastic Injection Mold Making: A Comprehensive Guide for Industrial Plastic Injection Machines”