Check out our leading manufacturer for the professional coil packing solution here: [insert manufacturer’s name or website]”.

Title: The AB-200 Semi-Automatic Plastic Injection Machine: Revolutionizing Small-Scale Plastic Injection

Introduction:

In the world of plastic injection, efficiency and precision are paramount. Whether you’re a hobbyist, a small-scale manufacturer, or a prototyping enthusiast, finding the right plastic injection machine can be a game-changer. Enter the AB-200 Semi-Automatic Plastic Injection Machine – a tabletop innovation designed to provide high-quality injection molding with a small footprint.

Opinion/Thought Piece Style:

As a sales engineer, I’ve witnessed the tremendous impact that the AB-200 has had on plastic injection processes. Its semi-automatic functionality, combined with its compact size, makes it an ideal choice for those seeking an efficient and cost-effective solution. In this article, we will explore the features and benefits of the AB-200, and how it has revolutionized the world of plastic injection.

Features and Benefits:

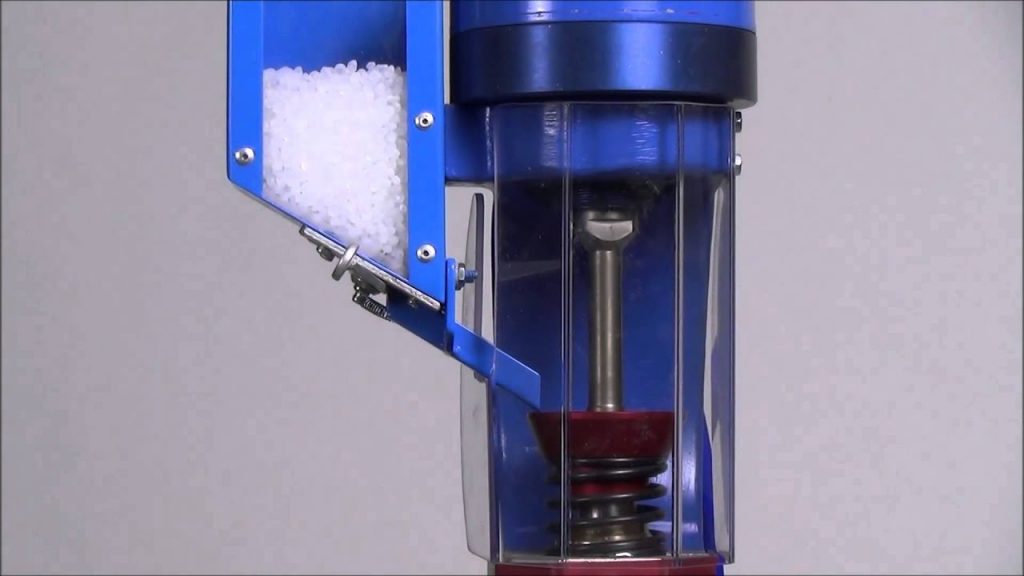

The AB-200 comes packed with features that make it an exceptional choice for plastic injection enthusiasts. Its semi-automatic operation allows for precise control over the injection process, ensuring consistent results with every cycle. The tabletop design makes it easy to integrate into any workspace, even in limited areas.

The AB-200 is equipped with a user-friendly interface, making it accessible to both beginners and experienced operators. Its intuitive controls and clear display provide real-time feedback, allowing users to adjust settings and monitor the injection process accurately.

One of the standout features of the AB-200 is its versatility. It can handle a wide range of materials, including ABS, polystyrene, polypropylene, and more. This versatility opens up endless possibilities for creating various plastic products, from prototypes to small-scale production runs.

The AB-200 also boasts impressive precision and accuracy, thanks to its advanced injection system. This system ensures that each mold is filled evenly and consistently, minimizing defects and maximizing productivity.

Case Study Style:

To illustrate the AB-200’s capabilities, let’s take a look at a real-life case study. Company XYZ, a small-scale manufacturer of plastic components, was struggling to meet the demand for their products. Their existing injection machine was slow and prone to errors, leading to increased production time and wasted materials.

Upon discovering the AB-200, Company XYZ decided to give it a try. The results were astounding. The AB-200’s semi-automatic operation allowed them to streamline their production process significantly. With its precise injection system, they were able to achieve consistent quality across their entire product line. The tabletop design also saved valuable floor space in their already cramped workspace.

Predictive/Foresight Style:

Looking ahead, the future of plastic injection is undeniably bright. The AB-200 has set a new standard for small-scale plastic injection machines, and we can expect further advancements in the field. As technology continues to evolve, we may see even more compact and efficient machines that offer enhanced features and capabilities.

Conclusion:

The AB-200 Semi-Automatic Plastic Injection Machine has emerged as a game-changer in the world of plastic injection. Its compact size, semi-automatic operation, and versatility make it a valuable tool for hobbyists, small-scale manufacturers, and prototyping enthusiasts alike. With its advanced injection system and user-friendly interface, the AB-200 ensures precision, efficiency, and consistent results. Embrace the future of plastic injection and explore the possibilities with the AB-200 today.

Check out our leading manufacturer for the professional coil packing solution here: [insert manufacturer’s name or website]. Plastic Injection Machine

“Efficient and Versatile Semi-Automatic Tabletop Plastic Injector – Optimize Your Injection Molding Process”