Title: Efficient and Cost-Effective Pallet Wrapping Machine | WCA-150

Description:

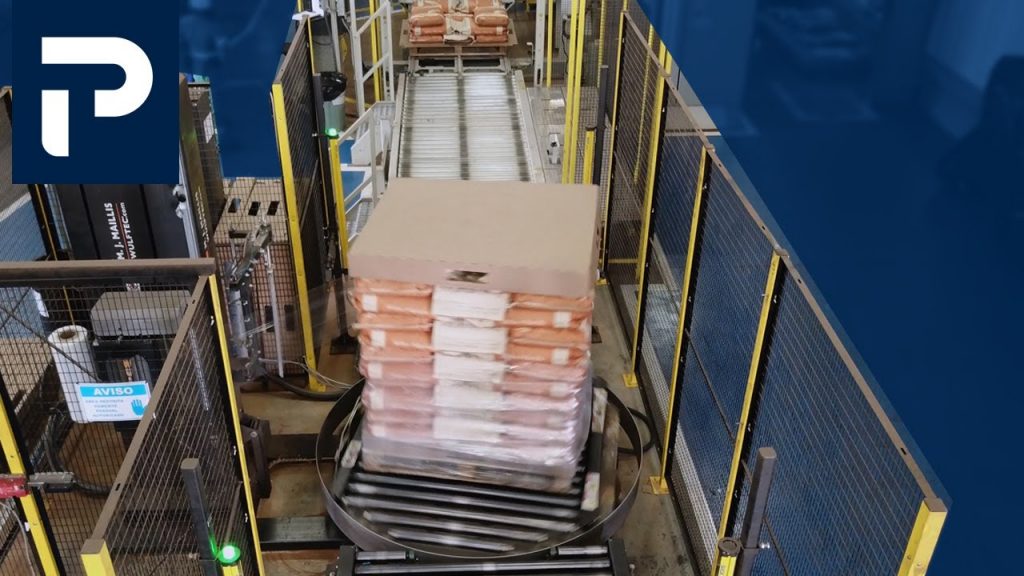

Welcome to our video showcasing the WCA-150 Automatic Turntable Stretch Wrapper, a heavy-duty system designed to revolutionize the pallet wrapping process. In this video, we will provide you with a comprehensive overview of this efficient and cost-effective pallet stretch wrap machine.

Introduction:

In this video, we will delve into the world of pallet wrapping machines and specifically focus on the WCA-150 Automatic Turntable Stretch Wrapper. This powerful system has been engineered to optimize your warehouse operations, ensuring secure and stable loads while saving time and resources.

Video Content:

1. Overview:

– Learn about the key features and benefits of the WCA-150 Automatic Turntable Stretch Wrapper.

– Discover how this machine can streamline your pallet wrapping process, reducing labor costs and enhancing efficiency.

– Gain insights into the high-quality materials and advanced technology employed in the construction of this heavy-duty system.

2. Operation Steps:

– Step 1: Prepare the pallet and load.

– Step 2: Place the load onto the turntable.

– Step 3: Set the desired wrapping parameters using the user-friendly control panel.

– Step 4: Activate the machine and watch as it automatically wraps the load securely.

– Step 5: Once the wrapping is complete, remove the wrapped load and repeat the process.

3. Key Highlights:

– Discover the incredible wrapping speed and accuracy of the WCA-150, ensuring consistent results every time.

– Explore the versatility of this machine, which can handle a wide range of load sizes and shapes.

– Learn about the innovative safety features incorporated into the design, ensuring the well-being of operators.

Call to Action:

If you found this video informative and useful, please consider liking, subscribing, and sharing it with others. Stay tuned for more insightful content related to pallet wrapping machines and industrial automation.

Additional Tags and Keywords:

pallet wrapping machine, pallet stretch wrap machine, WCA-150, automatic turntable stretch wrapper, efficient pallet wrapping, cost-effective wrapping solution, industrial automation, warehouse operations, secure load wrapping, labor cost reduction, advanced technology, user-friendly control panel, versatile wrapping machine, safety features

Hashtags:

#palletwrappingmachine #stretchwrapmachine #WCA150 #efficientwrapping #costeffectivewrapping #industrialautomation #warehousesolutions #secureloadwrapping

Here’s a sample tilter script for the Pallet stretch wrap machine WCA-150:

“`python

# Import necessary libraries

import RPi.GPIO as GPIO

import time

# Set GPIO mode

GPIO.setmode(GPIO.BCM)

# Set GPIO pins for the tilter motor

motor_pin1 = 18

motor_pin2 = 23

enable_pin = 24

# Set GPIO pins as output

GPIO.setup(motor_pin1, GPIO.OUT)

GPIO.setup(motor_pin2, GPIO.OUT)

GPIO.setup(enable_pin, GPIO.OUT)

# Function to tilt the pallet

def tilt_pallet():

# Enable the motor

GPIO.output(enable_pin, GPIO.HIGH)

# Rotate the motor in one direction to tilt the pallet

GPIO.output(motor_pin1, GPIO.HIGH)

GPIO.output(motor_pin2, GPIO.LOW)

# Wait for the desired tilt duration

time.sleep(5) # Adjust the duration as per your requirement

# Stop the motor

GPIO.output(motor_pin1, GPIO.LOW)

GPIO.output(motor_pin2, GPIO.LOW)

# Disable the motor

GPIO.output(enable_pin, GPIO.LOW)

# Call the tilt_pallet function to tilt the pallet

tilt_pallet()

# Clean up GPIO pins

GPIO.cleanup()

“`

Note: This is a basic example to tilt the pallet using a Raspberry Pi and the GPIO pins. You may need to modify the GPIO pin numbers according to your setup. Additionally, make sure to handle the safety precautions and any additional functionality specific to your Pallet stretch wrap machine WCA-150. pallet wrapping machine

#Pallet #stretch #wrap #machine #WCA150