Title: High-Speed Automatic Packing Line – FWC350 High Speed Flow Wrapper Demonstration

Description:

Introduction:

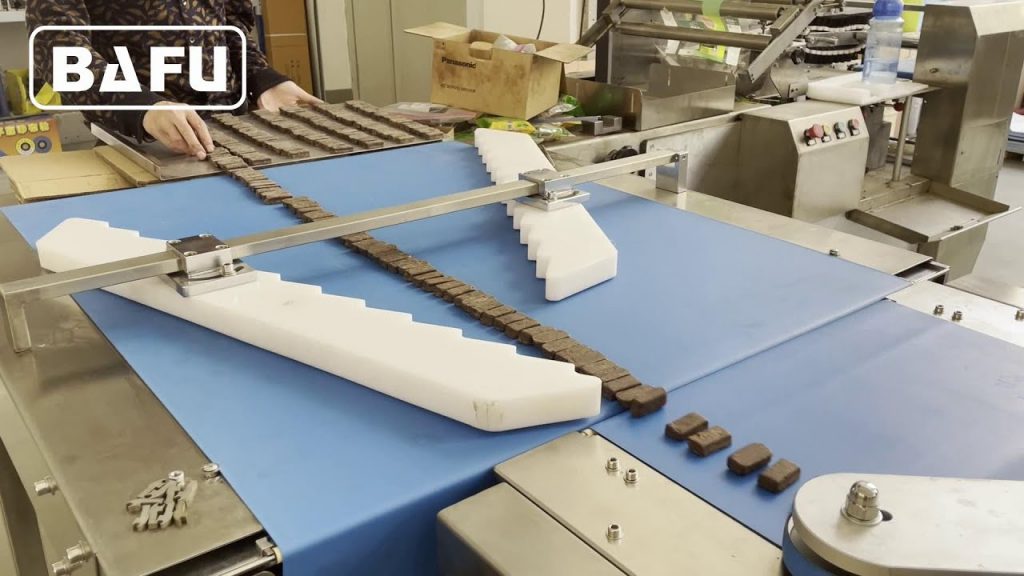

Welcome to this captivating video showcasing the operation of the FWC350 High-Speed Flow Wrapper, commissioned before shipment to North America. In this video, we bring you a comprehensive overview of the state-of-the-art features and functionalities of this high-speed automatic packing line, including the chocolate packaging machine, automatic packaging machine, and flow-pack machine.

Video Content:

In this video, we dive deep into the operation of the FWC350 High-Speed Flow Wrapper, a cutting-edge technology designed to streamline the packaging process with utmost efficiency. With its incredible speed and precision, this machine revolutionizes the packaging industry, offering a seamless solution for various products, especially in the chocolate packaging sector.

Key Highlights:

1. Unveiling the FWC350 High-Speed Flow Wrapper: We provide an up-close look at this advanced packaging machine, highlighting its sleek design and robust construction. Its innovative features ensure smooth and reliable operation, allowing for high-speed packaging while maintaining the product’s integrity.

2. High-Speed Performance: Witness the FWC350 in action as it flawlessly executes the packaging process at an impressive speed, ensuring a rapid and efficient production line. This machine is specifically designed to meet the demands of fast-paced manufacturing environments.

3. Versatility and Adaptability: The FWC350 Flow Wrapper offers exceptional flexibility, making it suitable for various products, including chocolates and other confectionery items. Its adjustable settings allow for seamless packaging of different sizes and shapes, ensuring a customized packaging experience.

4. Precise and Accurate Packaging: Experience the precision of the FWC350 as it consistently delivers perfectly sealed packages. Its advanced technology ensures minimal wastage and guarantees a tight seal to preserve the product’s freshness and quality.

Call to Action:

If you found this video informative and engaging, we encourage you to hit the like button, subscribe to our channel for more cutting-edge packaging solutions, and share this video with your peers in the industry. Stay updated with the latest advancements in the packaging world by subscribing to our newsletter.

Additional Tags and Keywords:

High-Speed Automatic Packing Line, Chocolate Packaging Machine, Automatic Packaging Machine, High-Speed Flow Wrapper, Flow-Pack Machine, FWC350, Packaging Industry, Packaging Solutions, Confectionery Packaging, Packaging Efficiency, Product Integrity, Precision Packaging, Customized Packaging.

Hashtags:

#HighSpeedPackingLine #FlowWrapperDemonstration #ChocolatePackaging #AutomaticPackaging #PackagingEfficiency

Title: Advanced Tilter for High-Speed Chocolate Packaging Machines

Introduction:

In the fast-paced world of chocolate packaging, automation and efficiency are key factors in meeting the demands of consumers. This tilter is designed to enhance the performance of automatic packaging machines, specifically high-speed flow wrappers or flow-pack machines. By seamlessly integrating into existing packaging lines, this advanced tilter ensures precise and efficient chocolate packaging, ultimately increasing productivity and customer satisfaction.

Key Features:

1. Intelligent Tiling System:

The tilter is equipped with a smart tiling system that precisely adjusts the packaging angle to optimize chocolate positioning within the packaging material. This ensures a consistent and visually appealing appearance for each chocolate product.

2. High-Speed Compatibility:

Designed specifically for high-speed flow wrappers, the tilter is capable of seamlessly integrating into existing packaging lines without compromising the overall speed of the process. It effectively keeps up with the rapid pace of the packaging machine, minimizing any potential bottlenecks.

3. Customizable Packaging Angles:

The tilter offers a wide range of customizable packaging angles, allowing manufacturers to cater to various chocolate shapes and sizes. From traditional rectangular bars to irregularly shaped confections, the tilter can accommodate diverse packaging requirements.

4. Precise and Gentle Handling:

To prevent damage to delicate chocolate products, the tilter utilizes advanced sensors and actuators to ensure precise and gentle handling. This reduces the risk of product deformation or breakage, maintaining the integrity of each chocolate piece throughout the packaging process.

5. Easy Integration and User-Friendly Interface:

The tilter is designed for easy integration into existing packaging lines, requiring minimal adjustments or modifications. Additionally, it features a user-friendly interface with intuitive controls, allowing operators to set and adjust parameters effortlessly.

6. Durable and Hygienic Construction:

Constructed from high-quality materials, the tilter is built to withstand the rigors of continuous operation. Its hygienic design adheres to strict industry standards, enabling easy cleaning and maintenance, ensuring a safe and contamination-free chocolate packaging process.

Conclusion:

Enhancing the capabilities of high-speed flow wrappers or flow-pack machines, this advanced tilter revolutionizes the chocolate packaging industry. By offering precise tiling, high-speed compatibility, customizable angles, gentle handling, easy integration, and durability, it enables manufacturers to streamline their operations and meet the growing demands of the market. This tilter ultimately ensures efficient and visually appealing chocolate packaging, contributing to customer satisfaction and brand reputation. coil packing line

#chocolate #packaging #machine #automatic #packaging #machine #high #speed #flow #wrapperflowpack #machine