Title: Efficient Pallet Wrapping Machine: Mastering Operations & Troubleshooting

Description:

Introduction:

Welcome to our comprehensive video on pallet wrapping machines! In this detailed guide, we will delve into the world of pallet wrapping machines and explore everything you need to know about their functionality, common issues, and troubleshooting techniques. Whether you are a beginner or an experienced operator, this video will equip you with the knowledge to efficiently operate and maintain your pallet wrapping machine.

Video Content:

1. Overview of Pallet Wrapping Machines:

– Understand the significance of pallet wrapping machines in optimizing packaging processes.

– Explore the various types and configurations available in the market.

2. Key Features and Benefits:

– Discover the essential features that make pallet wrapping machines a valuable asset.

– Learn about the benefits of using a pallet wrapping machine, including increased stability, reduced damage, and improved efficiency.

3. Operation Steps:

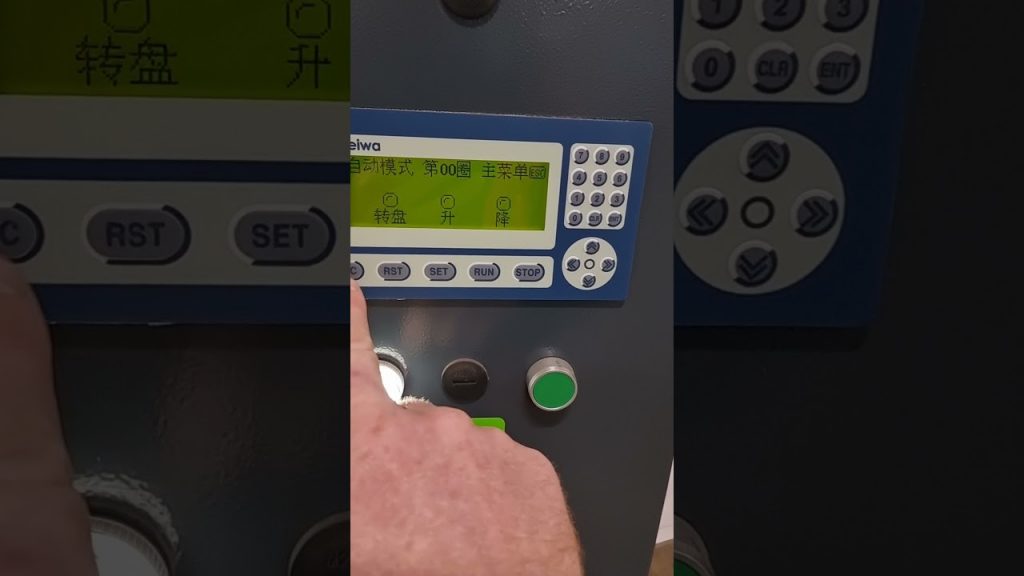

– Step-by-step guidance on setting up and operating a pallet wrapping machine.

– Detailed instructions on loading pallets, adjusting machine settings, and initiating the wrapping process.

4. Troubleshooting and Maintenance:

– Identify common issues that may occur during operation, such as film breakage or improper wrapping.

– Proven troubleshooting techniques to resolve these issues and ensure uninterrupted workflow.

– Essential maintenance tips to prolong the lifespan of your pallet wrapping machine and optimize its performance.

5. Safety Precautions:

– Highlight crucial safety measures to adhere to while operating a pallet wrapping machine.

– Ensure the well-being of operators and the surrounding environment.

Call to Action:

If you found this video informative and helpful, please give it a thumbs up, subscribe to our channel for more insightful content, and share it with others in your industry. Your support is greatly appreciated!

Additional Tags and Keywords:

pallet wrapping machine, malfunctioning pallet wrapping machine, pallet wrapper, pallet stretch wrapping, pallet wrapping process, troubleshooting pallet wrapping machine, maintenance tips, pallet wrapping machine operation, pallet stability, packaging efficiency.

Hashtags:

#PalletWrappingMachine #WrappingMachineTroubleshooting #PalletWrapper #PackagingEfficiency #PalletStability #MaintenanceTips

Title: Troubleshooting Guide for a Malfunctioning Pallet Wrapping Machine

Introduction:

A pallet wrapping machine is an essential tool for efficiently securing and protecting palletized loads. However, like any machinery, it may encounter malfunctions that require immediate attention. This troubleshooting guide aims to assist you in identifying and resolving common issues with a malfunctioning pallet wrapping machine.

Disclaimer:

Please note that this guide is for informational purposes only. Always prioritize safety and refer to the manufacturer’s manual or consult a professional technician if you are uncertain about performing any troubleshooting steps.

Table of Contents:

1. Safety Precautions

2. Initial Checks

3. Common Malfunctions and Troubleshooting Steps

a. Wrapping Film Breaks or Tears

b. Wrapping Film Slips or Doesn’t Hold

c. Machine Fails to Start or Operate

d. Wrapping Film Not Applied Properly

e. Wrapping Machine Produces Excessive Noise

f. Machine Does Not Cut the Wrapping Film

g. Wrapping Machine Jams

4. Preventive Maintenance

5. Conclusion

1. Safety Precautions:

Before attempting any troubleshooting steps, ensure that the machine is powered off and disconnected from the power source. Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, when working with the machine.

2. Initial Checks:

– Inspect the power cord and ensure it is securely connected to a functional outlet.

– Confirm that the emergency stop button is not engaged.

– Check the control panel for any error codes or indicators that might provide clues about the malfunction.

3. Common Malfunctions and Troubleshooting Steps:

a. Wrapping Film Breaks or Tears:

– Ensure that the wrapping film roll is properly mounted with its tension adjusted correctly.

– Inspect the film carriage for any obstructions or irregularities that could cause the film to tear.

– Verify that the film tension brake is not too tight, as excessive tension can cause film breakage.

b. Wrapping Film Slips or Doesn’t Hold:

– Check for any debris on the rollers or the turntable that might affect film adherence.

– Adjust the film tension to ensure it is neither too loose nor too tight.

– Inspect the film clamp and ensure it is gripping the film securely.

c. Machine Fails to Start or Operate:

– Verify that the power source is functioning correctly.

– Check the control panel for any error messages and follow the manufacturer’s instructions for resetting or clearing them.

– Inspect the machine’s fuses and circuit breakers, replacing or resetting them if necessary.

d. Wrapping Film Not Applied Properly:

– Ensure that the load is centered and positioned correctly on the turntable.

– Adjust the machine’s settings, such as the number of rotations or pre-stretch factor, to optimize film application.

– Verify that the film carriage moves smoothly without any mechanical obstructions.

e. Wrapping Machine Produces Excessive Noise:

– Inspect the machine’s moving parts, including the turntable and film carriage, for any loose or damaged components.

– Lubricate the machine’s bearings or other appropriate parts according to the manufacturer’s recommendations.

– Contact a professional technician if the noise persists, as it may indicate a more complex mechanical issue.

f. Machine Does Not Cut the Wrapping Film:

– Ensure that the cutting mechanism is not obstructed by debris or excess film.

– Adjust the cutting blade’s position and verify that it is sharp enough to cut through the film.

– Consult the machine’s manual for instructions on adjusting or replacing the cutting blade if necessary.

g. Wrapping Machine Jams:

– Power off and disconnect the machine from the power source.

– Gently remove any obstructions or tangled film from the machine’s components, such as the rollers or turntable.

– Inspect the sensor mechanisms to ensure they are clean and functioning correctly.

4. Preventive Maintenance:

Regular preventive maintenance is crucial to keep your pallet wrapping machine in optimal condition. Consult the manufacturer’s manual for recommended maintenance schedules and procedures. This may include cleaning, lubrication, and inspection of various components.

5. Conclusion:

By following this troubleshooting guide, you should be able to identify and resolve common malfunctions in a pallet wrapping machine. However, if the issue persists or if you are unsure about performing any troubleshooting steps, it is advisable to contact a professional technician or the machine’s manufacturer for further assistance. Remember to prioritize safety at all times and refer to the manufacturer’s manual for specific instructions relevant to your machine model. pallet wrapping machine

#Malfunctioning #pallet #wrapping #machine