Robotic Stretch Wrapper – Improve Efficiency and Productivity in Factory Automation

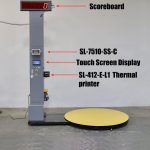

In today’s fast-paced industrial landscape, companies are constantly seeking ways to optimize their manufacturing processes and increase productivity. One such solution that has gained significant traction is the implementation of robotic stretch wrappers. These advanced machines, offered by Apex Automation and Robotics, an Australian company specializing in factory automation, revolutionize the packaging process by automating the wrapping of pallets with stretch film.

Robotic stretch wrappers are designed to streamline the packaging workflow in factories. With their precise and efficient operation, they eliminate the need for manual labor, reduce the risk of human error, and significantly increase productivity. This technology not only improves the overall efficiency of the packaging process but also ensures consistent and secure wrapping, leading to enhanced product protection during transit.

One of the key advantages of utilizing robotic stretch wrappers lies in their ability to adapt to various packaging requirements. These machines can handle a wide range of pallet sizes and shapes, making them suitable for diverse industries and applications. Whether it’s wrapping pallets of different heights or accommodating irregularly shaped loads, the robotic stretch wrapper can be easily programmed to meet specific packaging needs.

Moreover, robotic stretch wrappers offer a high level of flexibility and customization. The machines can be integrated seamlessly into existing production lines, enabling a smooth transition to automated packaging. By harnessing advanced software and control systems, manufacturers have the freedom to tailor the wrapping process to their unique requirements. This level of customization ensures optimal efficiency and minimizes wastage of stretch film, resulting in significant cost savings for businesses.

In addition to efficiency and customization, robotic stretch wrappers also excel in terms of safety. These machines are equipped with advanced safety features, including sensors and emergency stop buttons, to ensure the well-being of operators and other personnel working in the vicinity. With the automated wrapping process, workers are no longer exposed to potential hazards associated with manual wrapping, such as strains, slips, and falls. This not only reduces the risk of workplace accidents but also improves overall employee morale and job satisfaction.

The benefits of robotic stretch wrappers extend beyond immediate efficiency gains. These machines contribute to a more sustainable and eco-friendly packaging process. By automating the wrapping process, manufacturers can reduce the amount of stretch film used, minimize waste, and promote responsible resource management. This not only aligns with environmental goals but also enhances the brand image of companies committed to sustainability.

As the demand for efficient and reliable packaging solutions continues to grow, robotic stretch wrappers offer a compelling solution for businesses across various industries. Apex Automation and Robotics, with their expertise in factory automation, provide cutting-edge robotic stretch wrappers that deliver exceptional performance and efficiency. By embracing this technology, manufacturers can optimize their packaging processes, increase productivity, and stay ahead of the competition.

Check the coil packing solution with the leading manufacturer for the professional solution just here. Stretch Wrapping Machine

“Efficient Robotic Palletising and Stretch Wrapping Solution: Maximize Productivity With Advanced Automation”